Recyclable food phase transition heating bag

A phase change heater and heating bag technology, applied in food heating containers, packaged food, sustainable manufacturing/processing, etc., can solve the problems of irritating gas generation, unsafe, non-reusable, etc., to reduce the probability of discovery , the effect of reducing temperature and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

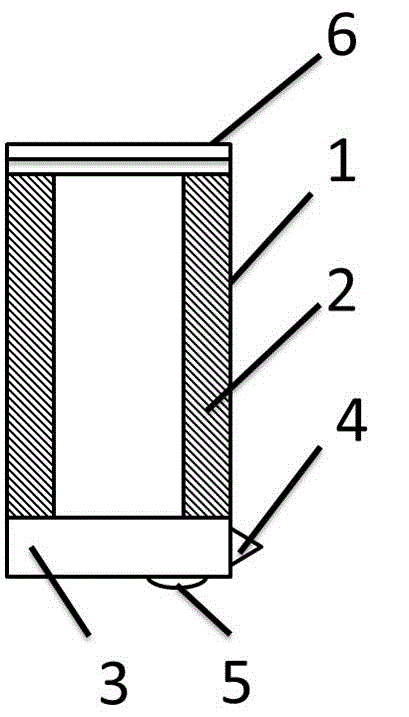

Image

Examples

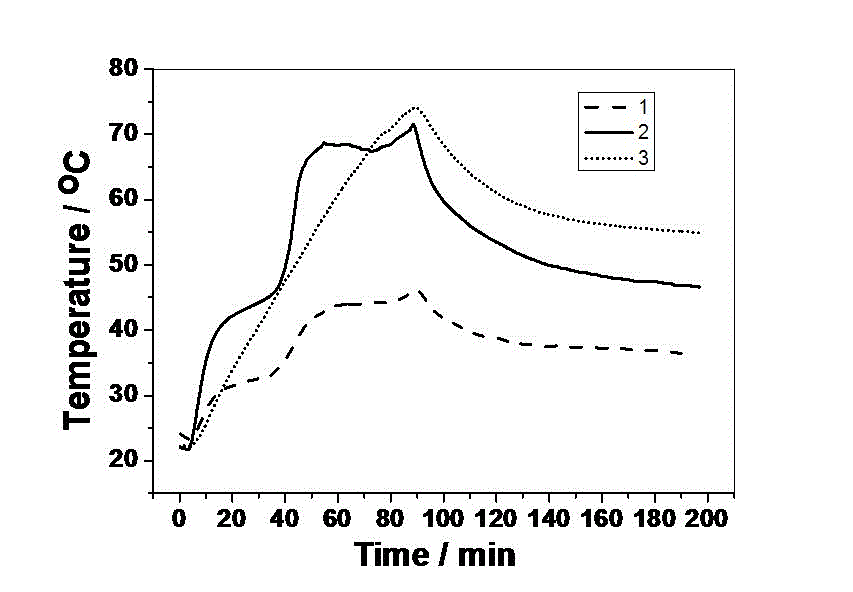

Embodiment 1

[0020] The phase change temperature of the phase change material used in this embodiment is 40° C., and the heating power source is a 12V storage battery.

[0021] The implementation process of the present embodiment is: encapsulating 300 grams of cooled boiled rice in the bag, the outside of the rice encapsulation bag ( figure 2 Curve 1), inside the rice ( figure 2 curve 2), and the outside of the insulated bag ( figure 2 Curve 3) Place three temperature probes to test the temperature change curve.

[0022] It can be seen from the curve change that when the heating time is 90 minutes, the internal temperature of the rice can reach 70°C, and the temperature outside the heat-insulating bag is only 43°C.

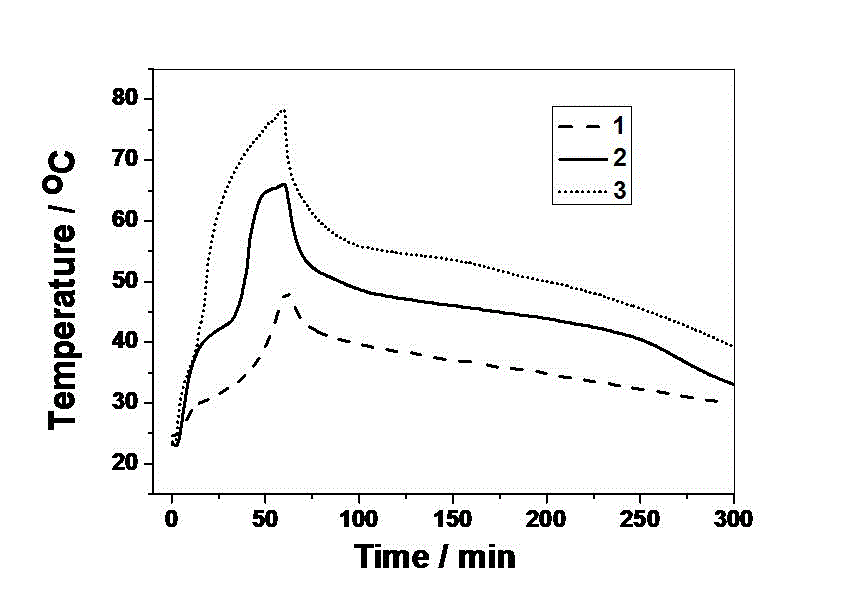

Embodiment 2

[0024] The phase change temperature of the phase change material used in this embodiment is 45° C., and the heating power is a 12V external power supply.

[0025] The implementation process of the present embodiment is: encapsulating 300 grams of cooled egg fried rice in a bag, and the outside of the egg fried rice packaging bag ( image 3 Curve 1), inside the egg fried rice ( image 3 curve 2), and the outside of the insulated bag ( image 3 Curve 3) Place three temperature probes to test the temperature change curve.

[0026] It can be seen from the change of the curve that when the heating time is 60 minutes, the temperature inside the egg and rice can reach 66°C, and the temperature outside the heat-insulating bag is only 46°C. At the same time, it can keep the food above 45°C for about 3 hours.

Embodiment 3

[0028] The phase change temperature of the phase change material used in this embodiment is 43° C., and the power source for heating is a 24V storage battery.

[0029] The implementation process of the present embodiment is: encapsulating 400 grams of military convenience food in the bag, the outside of the food packaging bag ( Figure 4 curve 1), the interior of the food ( Figure 4 curve 2), and the outside of the insulated bag ( Figure 4 Curve 3) Place three temperature probes to test the temperature change curve.

[0030] It can be seen from the change of the curve that when the heating time is 45 minutes, the temperature inside the food can reach 58°C, and the temperature outside the heat-insulating bag is only 47°C. At the same time, it can keep the food above 45°C for about 4 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com