Preparation method of tin-doped cuprous oxide

A cuprous oxide and tin doping technology, which is applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc., can solve complex preparation processes, low photocatalytic efficiency, Raw materials have toxicity and other problems, to achieve the effect of simple preparation process, rich and non-toxic, rich raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

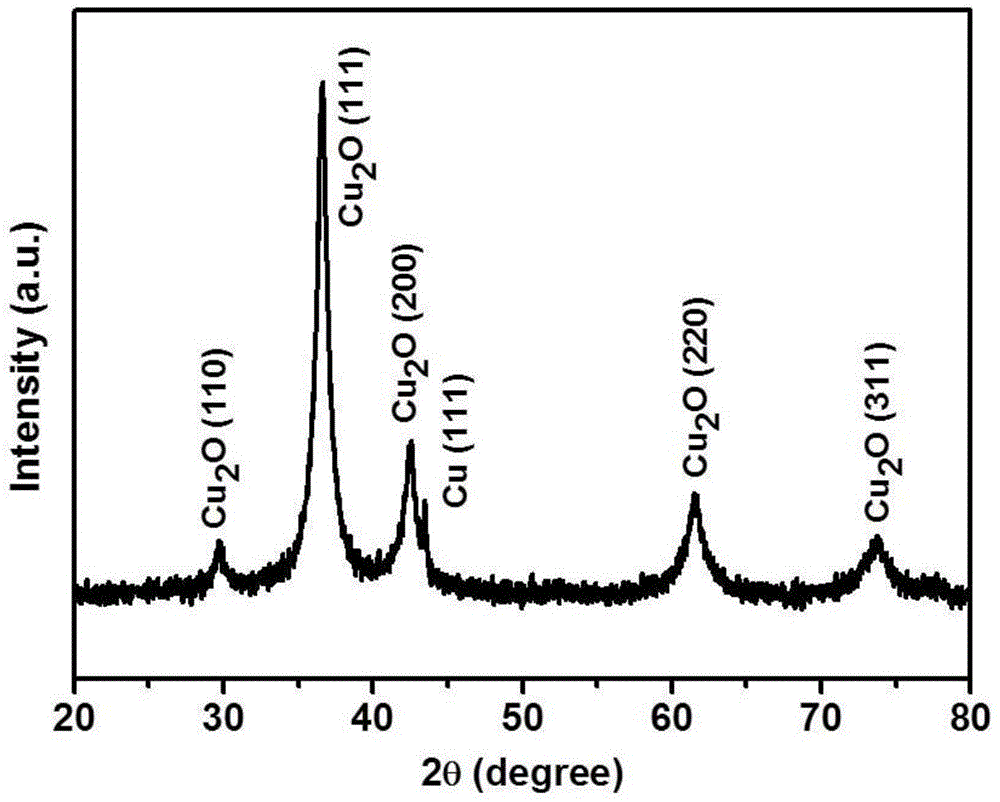

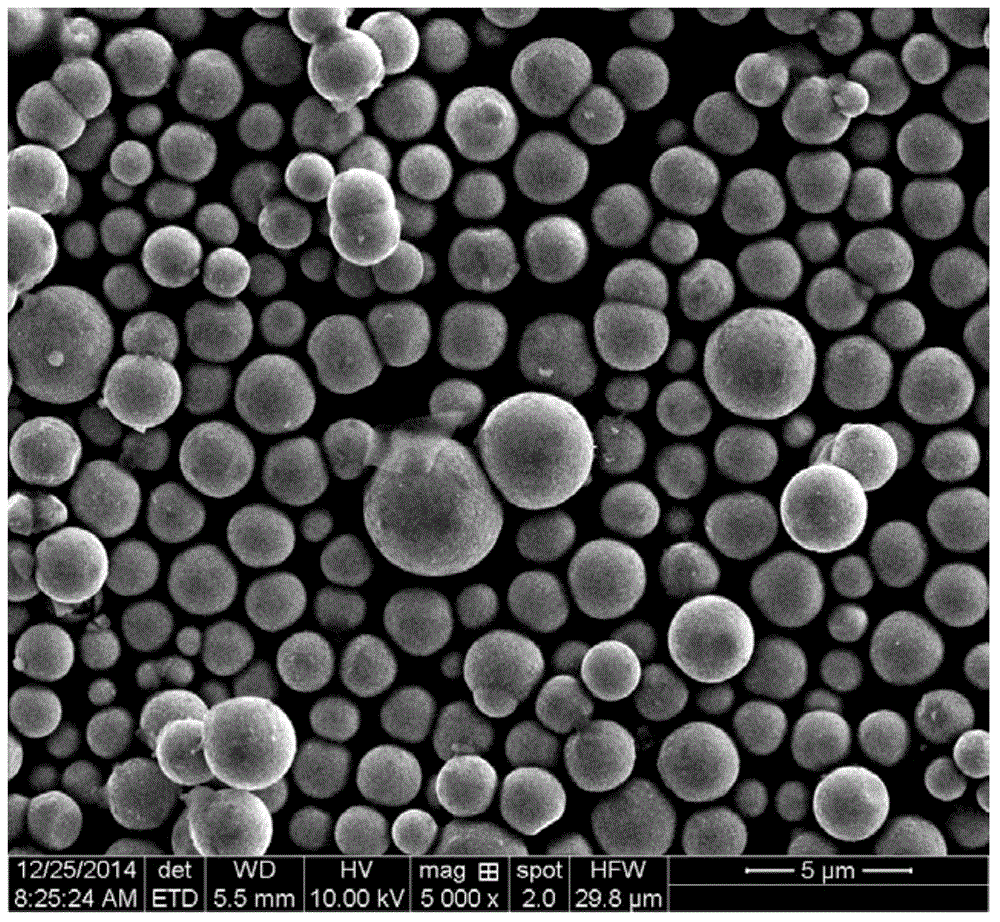

[0030] A method for preparing tin-doped cuprous oxide, first weigh 0.9664g copper nitrate (Cu(NO3)2·3H2O) and 0.0379g stannous chloride, add them to 80ml of ethylene glycol, and rotate at 600-800rpm Stir vigorously for 1 hour, then transfer to a 100ml autoclave, react at 140°C for 10 hours to obtain a precipitate; then wash 3 times with deionized water and absolute ethanol, and put it in a vacuum drying oven at 60°C for 12 hours Get the final product, see attached figure 1 , 3 , 4, and 7.

Embodiment 2

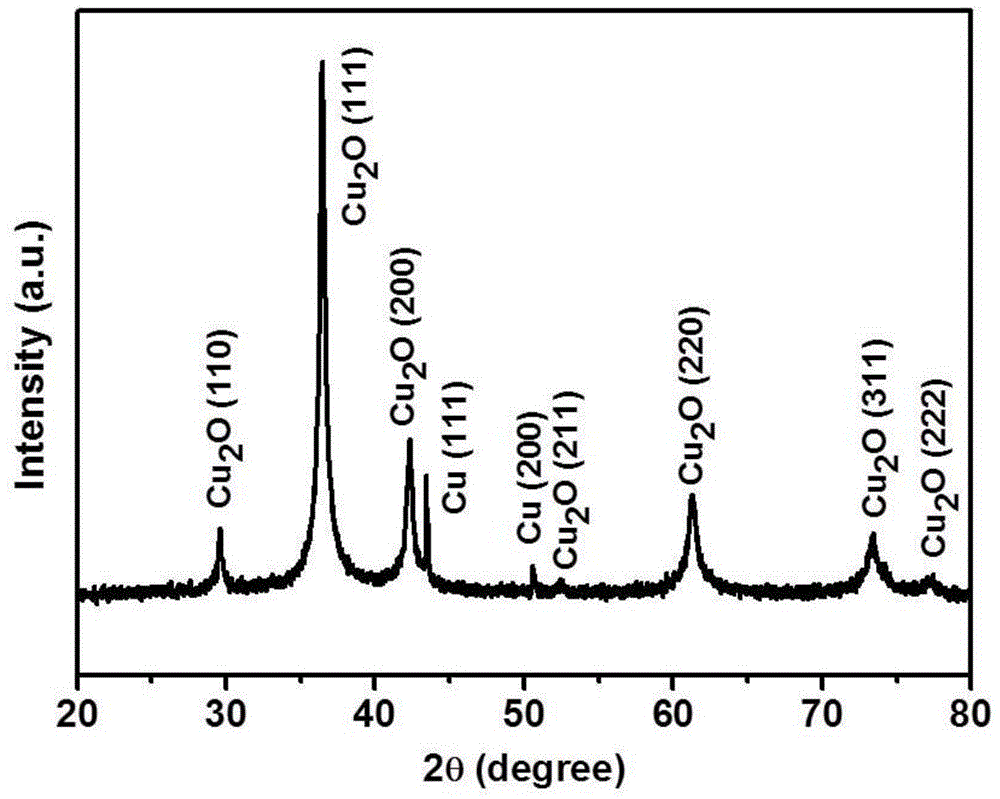

[0032] A preparation method of tin-doped cuprous oxide, first weigh 0.9664g copper nitrate (Cu(NO3)2·3H2O) and 0.0379g stannous chloride or 0.0701g tin chloride pentahydrate, and add them to 80ml of ethylene dichloride In alcohol, stir vigorously at 600-800rpm for 1 hour, then transfer to a 100ml autoclave, react at 140°C for 10 hours to obtain a precipitate; then wash with deionized water and absolute ethanol for 3 times, and put it into vacuum The final product is obtained in a drying oven at 60℃ for 12 hours, see attached figure 2 , 5 , 6 and 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com