III-nitride semiconductor/quantum dot hybrid white light LED device and preparing method thereof

A technology of nitride semiconductors and LED devices, which is applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of low conversion efficiency and long-term decay of yellow fluorescent pink, and achieve the effect of overcoming rough surfaces and improving luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

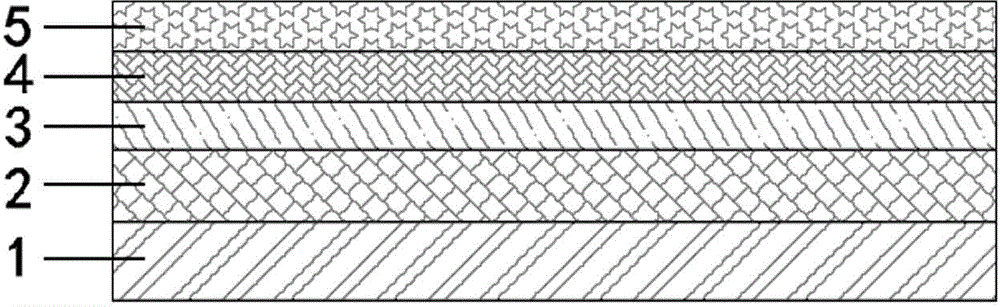

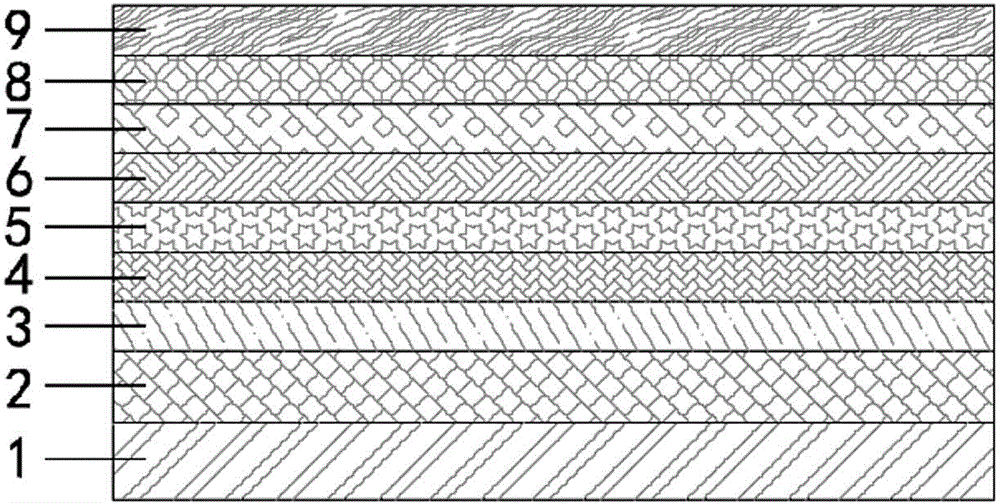

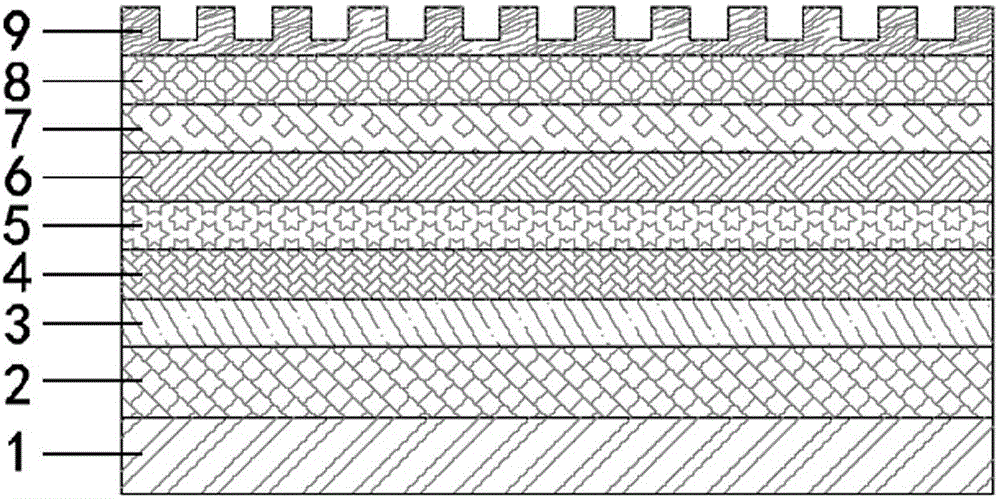

[0064] like Figure 1-11 Shown, the preparation method of this white light LED device, its step comprises:

[0065] 1) Select an InGaN / GaN quantum well LED substrate with x as 0.12, luminous wavelength as 430nm, period number of quantum well as 10, and thickness of p-type GaN as 300nm, and deposit a layer of ITO on it by electron beam evaporation technology , the thickness is 100nm, and then the sample is annealed at a high temperature in a rapid annealing furnace (RTA), the annealing temperature is 450°C, and the time is 2min;

[0066] 2) A layer of SiO was grown on the surface of the ITO layer by plasma-enhanced chemical vapor deposition 2 layer, with a thickness of 30 nm, was deposited on SiO by physical vapor deposition 2 A layer of Ni metal film layer is grown on the surface of the layer, the thickness is 10nm, and 200nm thick SU8 glue and 30nm thick UV curing glue are sequentially spin-coated on the surface of the Ni metal film layer;

[0067] 3) Using UV-NIL technolo...

Embodiment 2

[0078] like Figure 1-11 Shown, the preparation method of this white light LED device, its step comprises:

[0079] 1) Choose an InGaN / GaN quantum well LED substrate with x as 0.25, luminous wavelength as 480nm, period number of quantum well as 15, and thickness of p-type GaN as 500nm, and deposit an ITO layer on it by electron beam evaporation technology , the thickness is 200nm, and then the sample is annealed at a high temperature in a rapid annealing furnace (RTA), the annealing temperature is 600°C, and the time is 10min;

[0080] 2) A layer of SiN is grown on the surface of the ITO layer by plasma-enhanced chemical vapor deposition x layer, with a thickness of 300nm, was deposited on Si by physical vapor deposition 3 N 4 A layer of Cr metal film layer is grown on the surface of the layer, and the thickness is 50nm. The SU8 glue with a thickness of 600nm and the UV curing glue with a thickness of 300nm are spin-coated on the surface of the Cr metal film layer in turn; ...

Embodiment 3

[0092] like Figure 1-11 Shown, the preparation method of this white light LED device, its step comprises:

[0093] 1) Choose an InGaN / GaN quantum well LED substrate with x as 0.18, luminous wavelength as 450nm, period number of quantum well as 12, and thickness of p-type GaN as 400nm, and deposit a layer of ITO on it by electron beam evaporation technology , the thickness is 150nm, and then the sample is annealed at a high temperature in a rapid annealing furnace (RTA), the annealing temperature is 500°C, and the time is 6min;

[0094] 2) A layer of SiN is grown on the surface of the ITO layer by plasma-enhanced chemical vapor deposition x layer, with a thickness of 160 nm, was deposited on Si by physical vapor deposition 3 N 4 A layer of Al metal film layer is grown on the surface of the layer, the thickness is 30nm, and 450nm thick SU8 glue and 160nm thick UV curing glue are sequentially spin-coated on the surface of the Al metal film layer;

[0095] 3) Using UV-NIL tec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Luminous wavelength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com