An In-Situ Measurement Method of Complex Curved Surface of Blade

A complex curved surface, in-situ measurement technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of unfavorable measurement accuracy stability, measurement accuracy depends on the movement accuracy of measurement equipment, etc., to avoid secondary clamping errors, Improve efficiency and accuracy, and evenly collect points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Include the following steps:

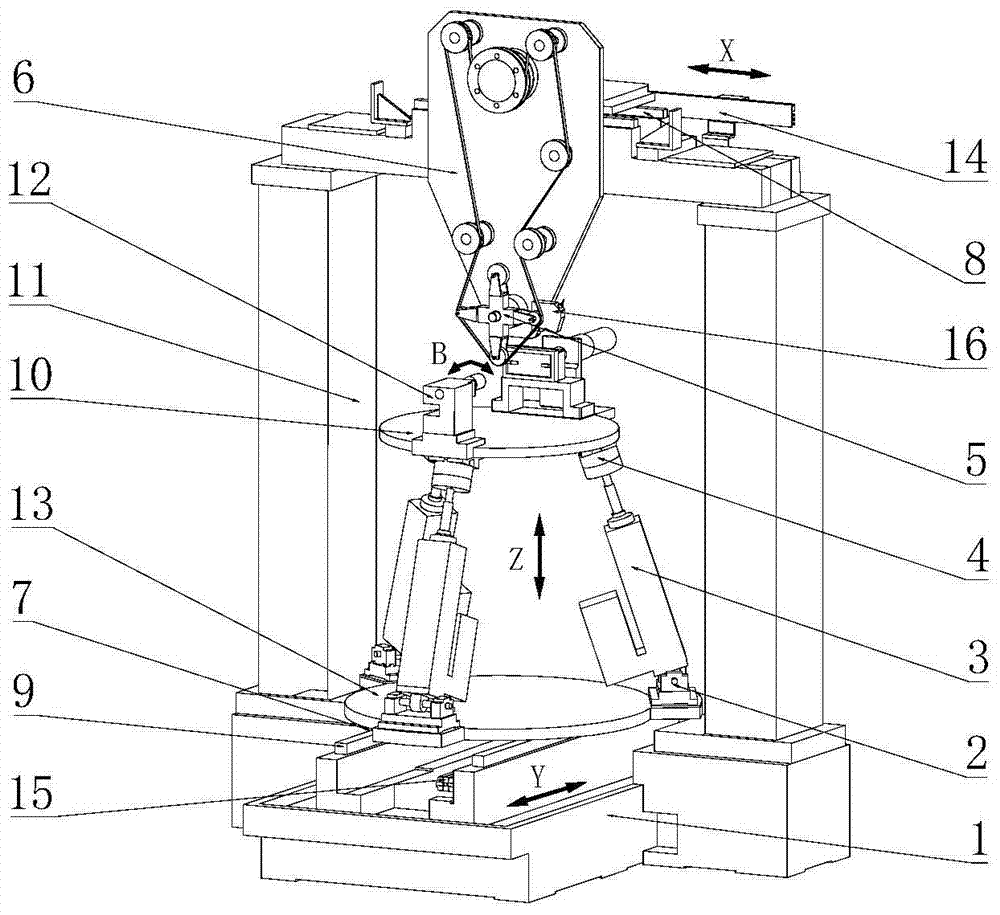

[0037] (1) Install the laser displacement sensor on the tool plate of the polishing machine to align the position of the measuring point;

[0038] (2) Adjust the height of the workbench to ensure that the blade does not interfere with the tool plate when it rotates, and determine the vertical distance Z between the top axis of the fixture and the sensor at this time;

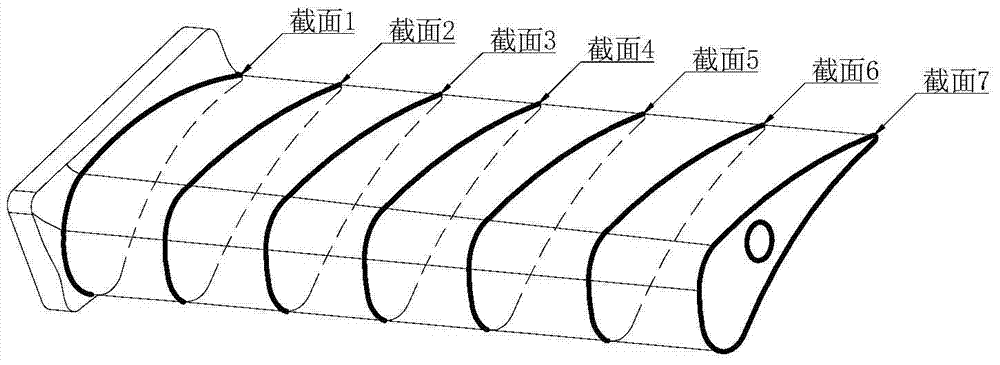

[0039] (3) Seven sections are selected at equal intervals along the length direction of the blade as the measurement section;

[0040] (4) Move the worktable through the longitudinal slideway so that the laser sensor is located directly above the initial section to be measured;

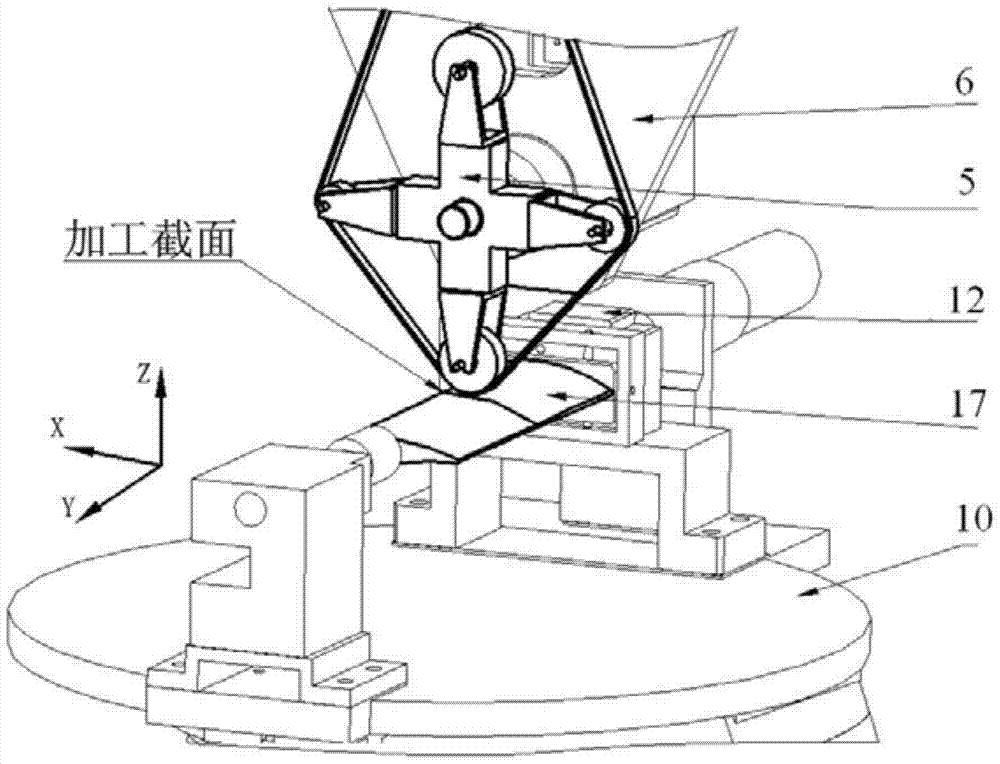

[0041] (5) In the section to be measured, establish a polar coordinate system;

[0042](6) Plan and partition the measurement section, control the flipping fixture motor, adopt the non-uniform rotation measurement method of the blade, and rotate one circle at a non-uniform speed according to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com