Production method of flat plate type VIP with groove and refrigerator applying flat plate type VIP

A production method and technology for refrigerating cabinets, which are used in household refrigeration devices, applications, household appliances, etc., can solve problems such as affecting energy-saving effect and product quality, low thermal conductivity of aluminized film, and increased thermal conductivity, and achieve stable quality. Control, expansion and long life, high tensile strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

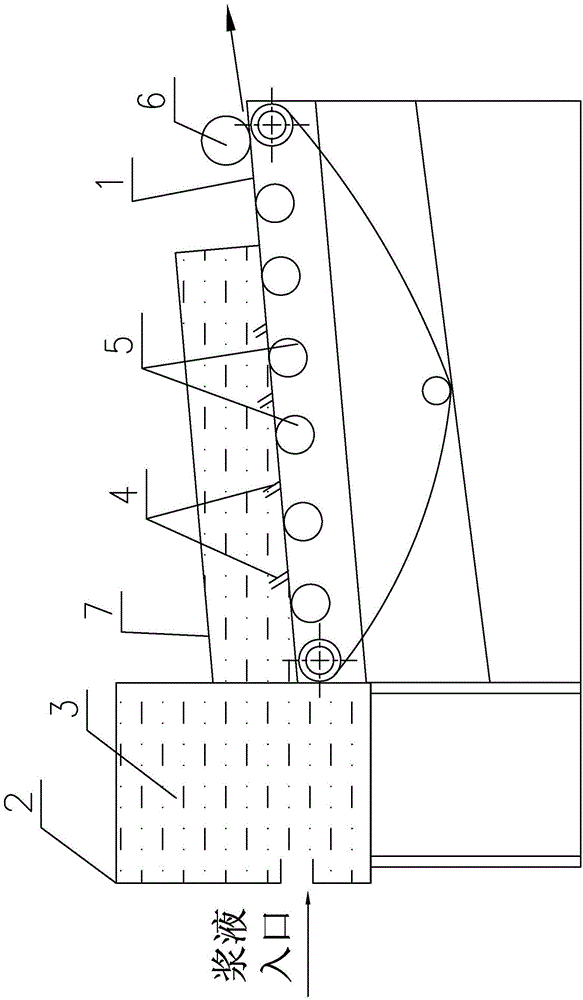

[0064] The production method of the vacuum heat insulation panel of this embodiment includes: putting the core material whose upper and lower sides are flat into the packaging film bag, and then putting it into the cavity of the vacuum device, and placing the core material on the upper side or the lower side of the packaging film bag. Place a compact on the side for pressing grooves or protrusions on the core material during vacuuming, then close the vacuuming device and implement vacuuming; wherein, during vacuuming, in the cavity , pressing the briquetting block or a pressing plate to one side of the packaging film bag (when applying pressure, the pressing plate is on the back of the briquetting block, or the pressing block and the pressing plate are respectively on the upper and lower sides of the packaging film bag), To press the groove or protrusion on the core material through the pressing block; when the vacuum is completed, the opening of the packaging film bag is heat-...

Embodiment 2

[0069] On the basis of Embodiment 1, the production method of the vacuum insulation panel of this embodiment has the following modifications:

[0070]The production method of the vacuum heat insulation panel in this embodiment includes: putting the core material whose upper and lower sides are flat into the packaging film bag, and then putting it into the cavity of the vacuum pumping device for vacuuming, and then putting the core material of the packaging film bag The opening is heat-sealed; then, place a briquetting block for pressing a groove or a protrusion on the core material when vacuuming on the upper side or the lower side of the packaging film bag, and place the briquetting block or a pressing plate toward the One side of the packaging film bag is pressed to press the groove or protrusion on the core material through the pressing block; then, the vacuum insulation panel is taken out from the cavity, and then Manual folding, that is, the finished product.

[0071] As...

Embodiment 3

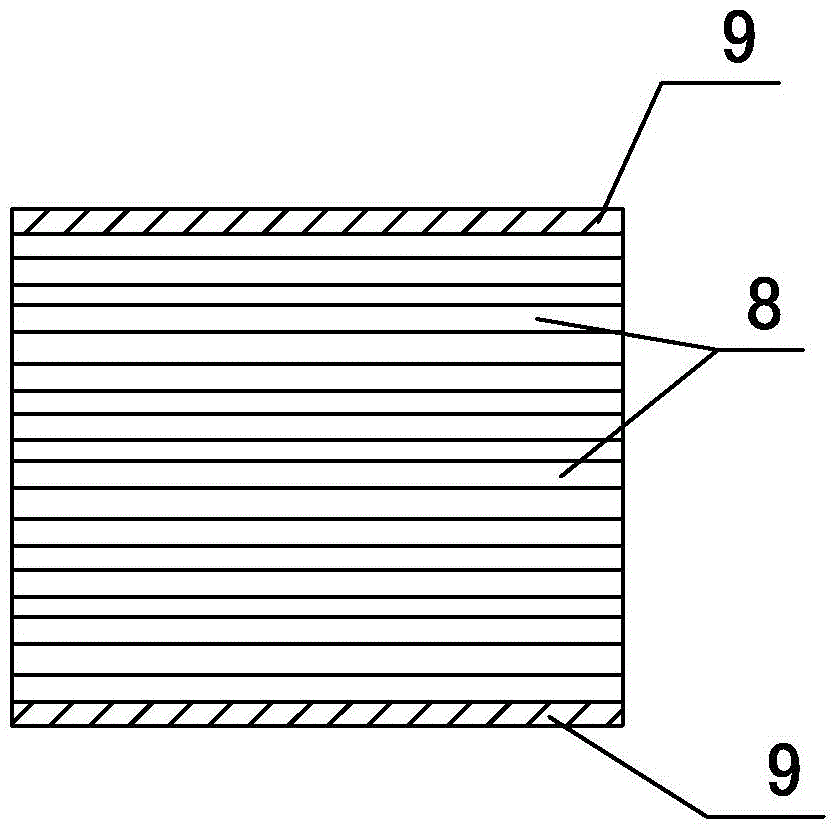

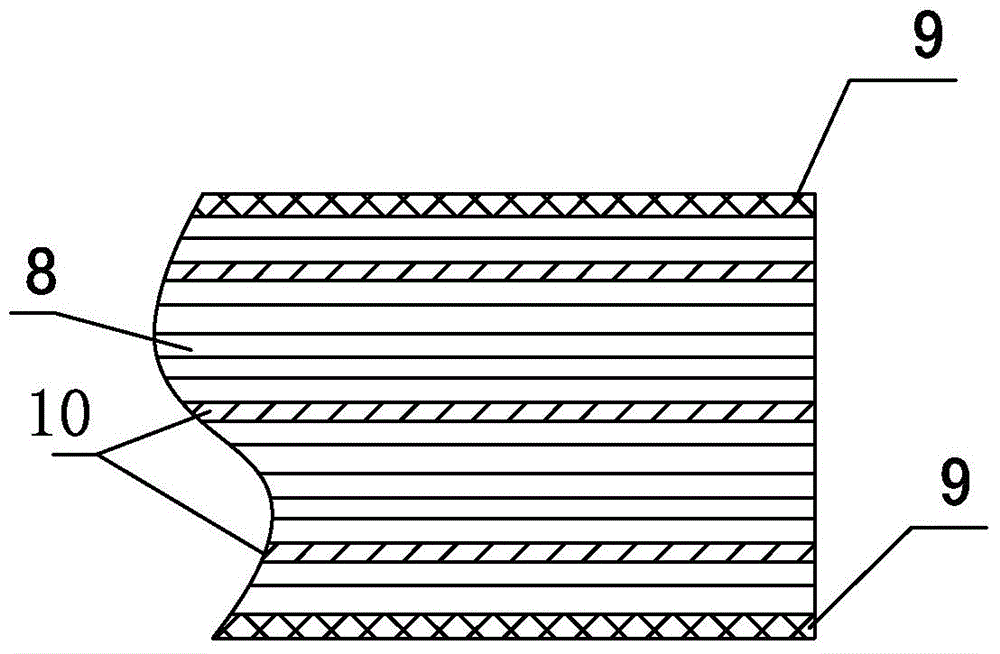

[0073] The packaging film for vacuum insulation panels of the above-mentioned embodiment 1 or 2 has the characteristics of a large temperature resistance range and flame retardancy, and includes: a protective layer, a gas barrier layer and a heat-welding layer, and the heat-sealing layer is an ETFE material layer, Its thickness is 15-95 μm.

[0074] As the protective layer, a coextruded stretched film (hereinafter referred to as a coextruded stretched film) obtained by sequentially laminating a nylon-based resin, an ethylene-vinyl alcohol copolymer, and a nylon-based resin is used. This co-extruded stretched film does not use an adhesive, but by co-extruding, a flexible nylon-based resin is laminated on both sides of the gas-barrier ethylene-vinyl alcohol copolymer to give it flexibility. and gas barrier properties.

[0075] As the gas barrier layer, a metal foil, a plastic film formed with a thin film layer of metal or metal oxide, or a combination of these can be used.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com