Wall decorative panels with upvc material

A wall decoration, LFUPV-001 technology, applied in covering/lining, building, building construction, etc., can solve the problems of long preparation and construction time, complicated manufacturing process, complicated construction, etc., and achieve easy cleaning and maintenance, flow ratio Suitable, good melting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

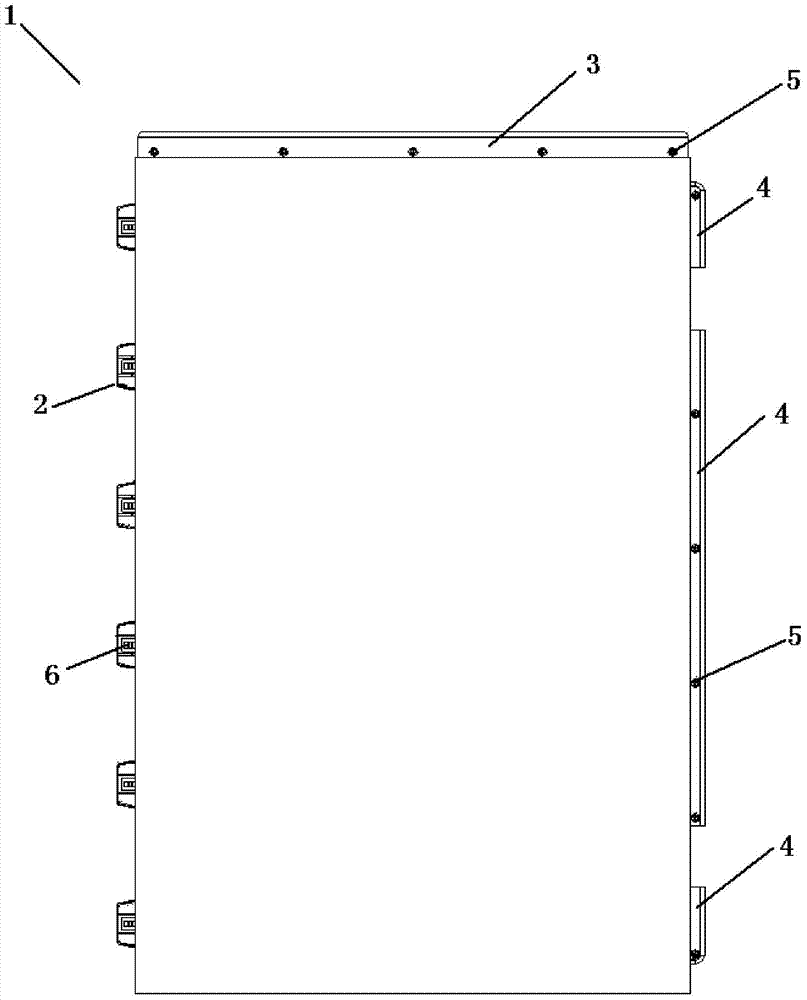

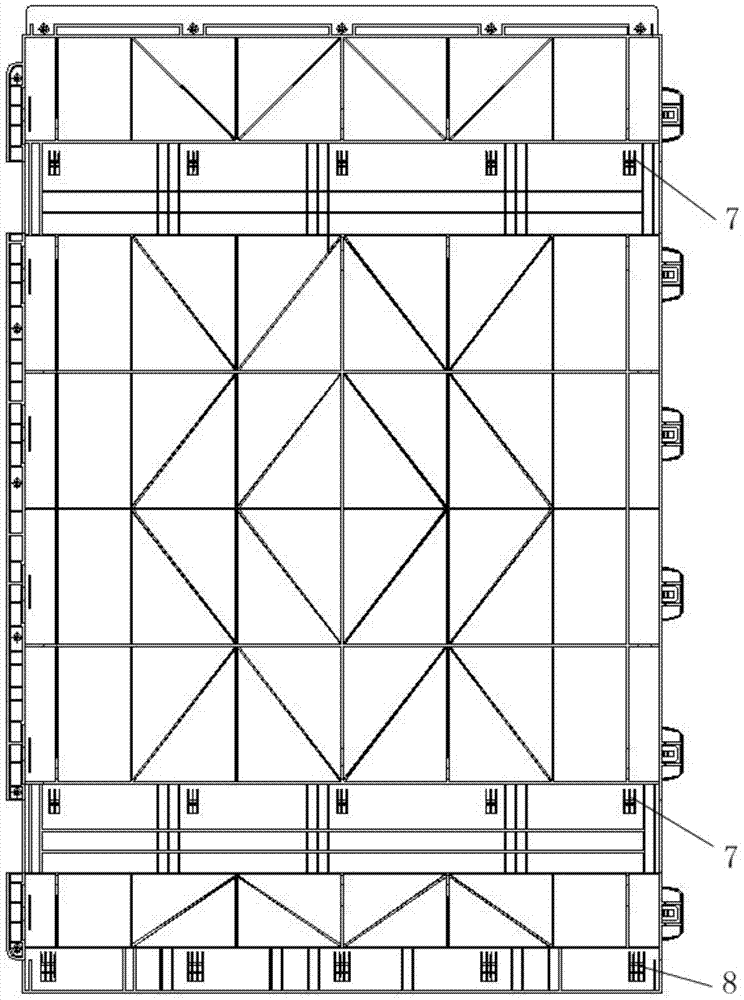

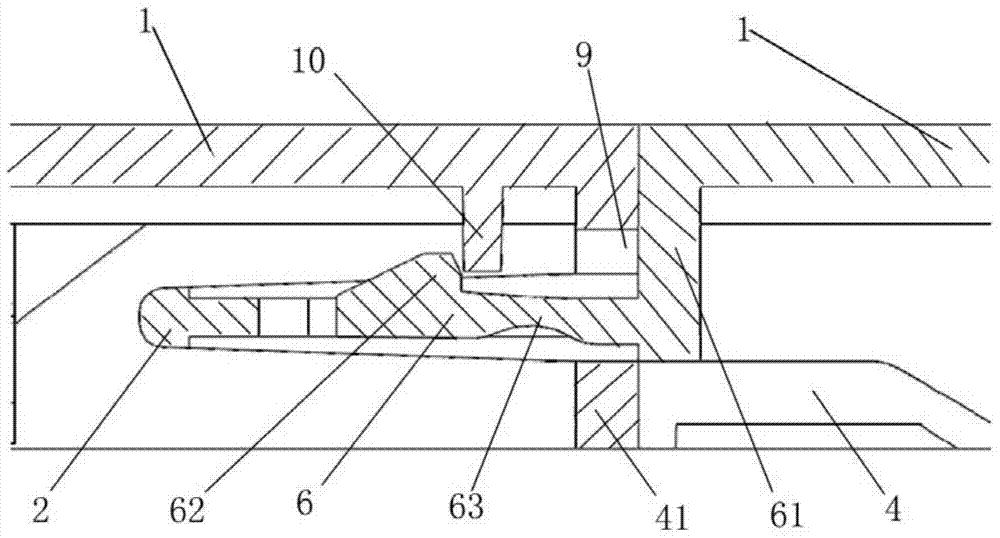

[0039] Such as Figure 1-7 As shown, the present invention provides a wall decoration board using UPVC material.

[0040] Among them, UPVC material adopts LFUPV-001 type, and its density is 1.4g / cm 3, the melt index is 215 at 390-400 degrees Fahrenheit, the heat distortion temperature is 70-74 below 264Pa, the oxidation index is 36%, the combustion level is V-O / 5VA, the weather resistance level is F-1, and the burning speed index is RP- 42. The UPVC material adopts an injection molding process, wherein: the range of molding shrinkage is 0.2-0.6%, the range of injection pressure is 60-150mPa, the range of injection temperature is 165°-205°, and the range of mold temperature is 40°- 50°, injection speed is 20-50cm 3 / min. Compared with traditional materials such as raw wood, stone, ceramics, and glass, UPVC materials are easy to form, high in productivity, low in cost, and easy to make into various colors; they are light in weight, easy to cut, and flexible in construction. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com