Concrete crack electrolytic deposition repair system capable of realizing self-supply of electrolyte

A crack system and concrete technology, applied in the field of repair systems, can solve the problems of limited field of electrodeposition repair cracks, and achieve the effects of wide application range, simple construction and good repair effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

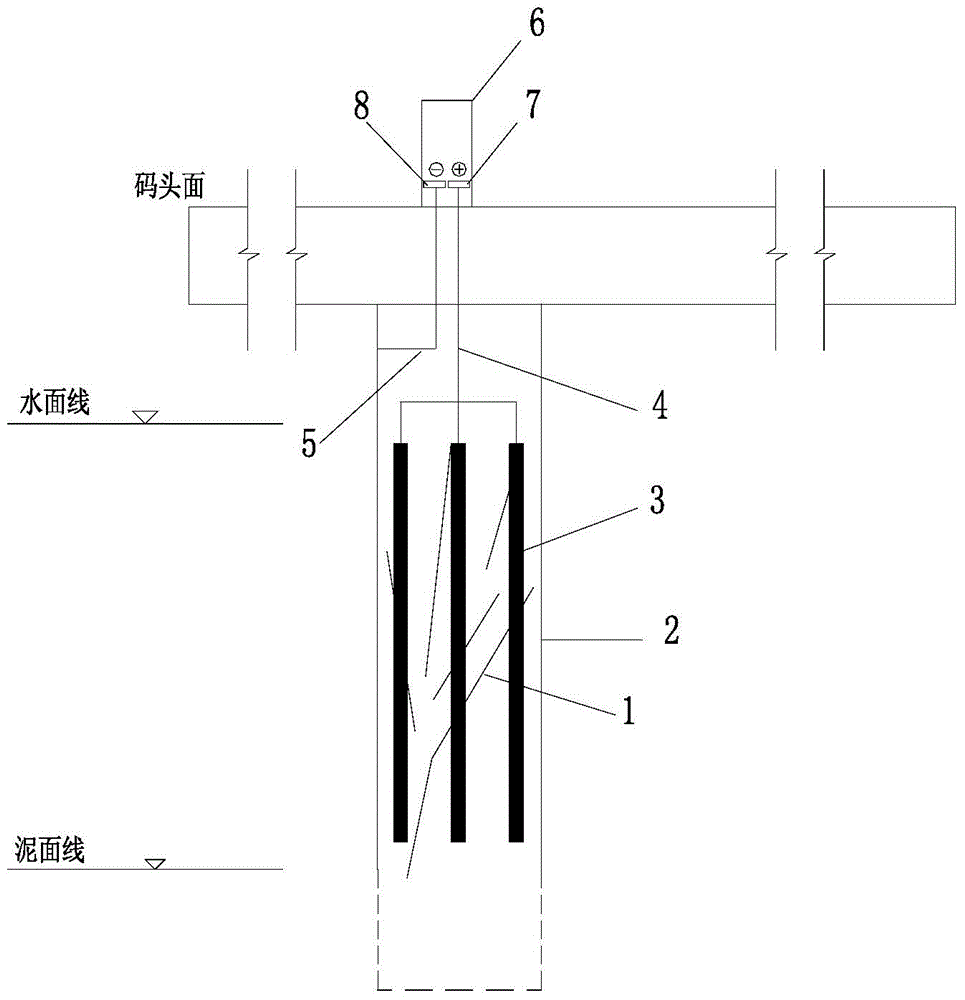

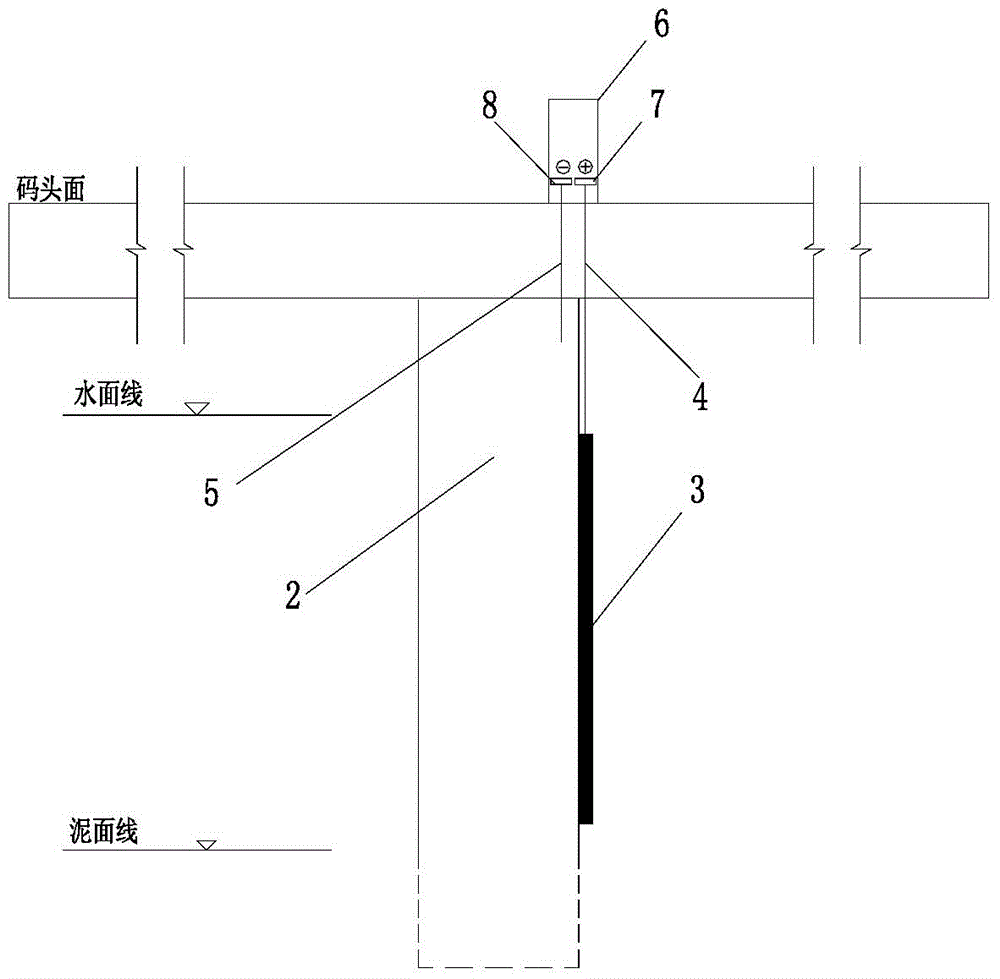

[0019] Taking the repair of the concrete square pile 2 of the inland wharf as an example, the electrodeposition repairing concrete crack system with self-providing electrolyte is illustrated. The concrete square pile is inserted below the water surface and stands on the mud surface.

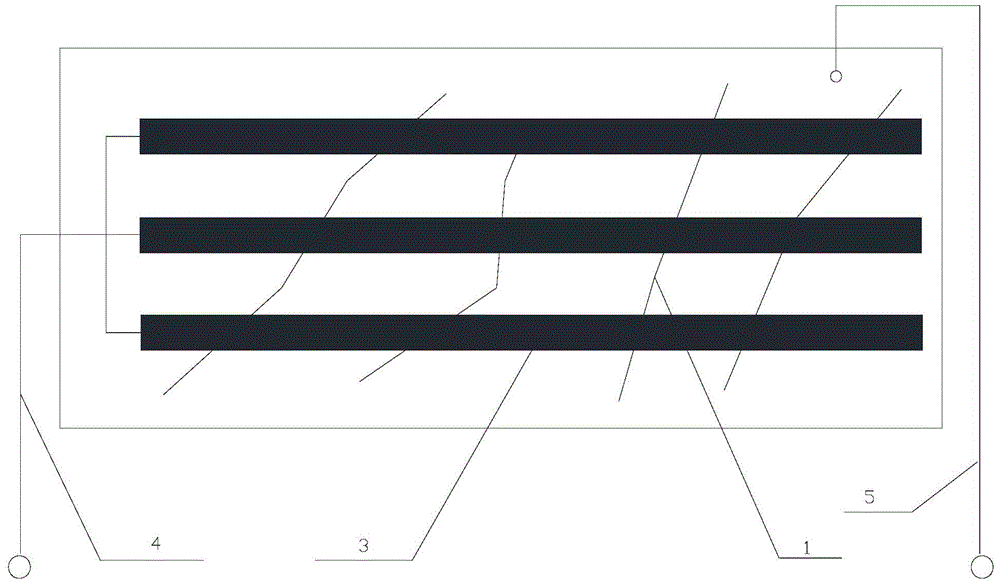

[0020] refer to figure 1 , 2, give the front view and side view of the repaired concrete square pile crack respectively. The cross-sectional size of the concrete square pile is 500mm×500mm, and there are cracks 1 and holes on the surface of the structure.

[0021] The system for repairing concrete cracks by electrodeposition according to the present invention is set: the cathode is the steel bar in the concrete member to be repaired. Draw a cable from the steel bar in the concrete member to be repaired as the cathode lead wire 5, and seal the cathode lead wire position with insulating materials such as mortar or epoxy resin.

[0022] A magnesium or zinc anode is used as the anode 3, the anode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com