Spring liquor brewed for nine times and preparation method of spring liquor

A technology of spring wine and alcohol content, which is applied in the field of Jiuyunchun wine and its semi-solid and liquid fermentation, which can solve the problems of low content of aroma substances, short fermentation cycle, and poor flavor of Xiaoqu wine, and achieve elegant honey flavor and comfortable aroma Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

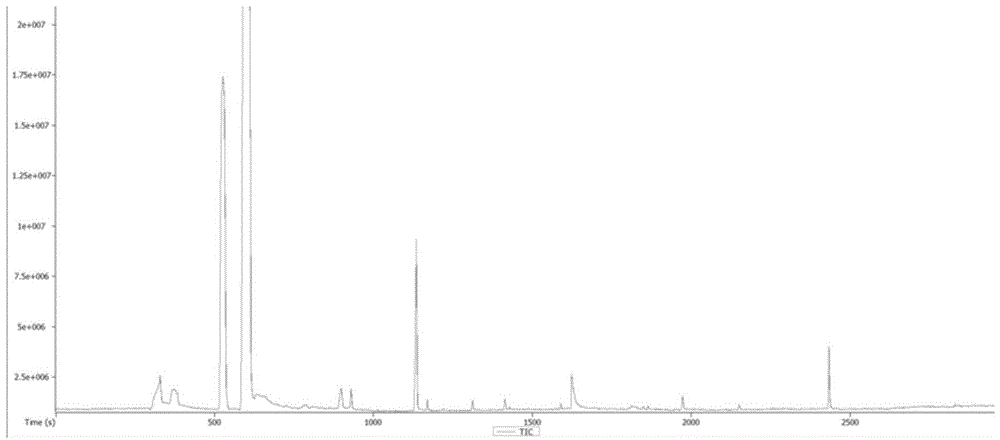

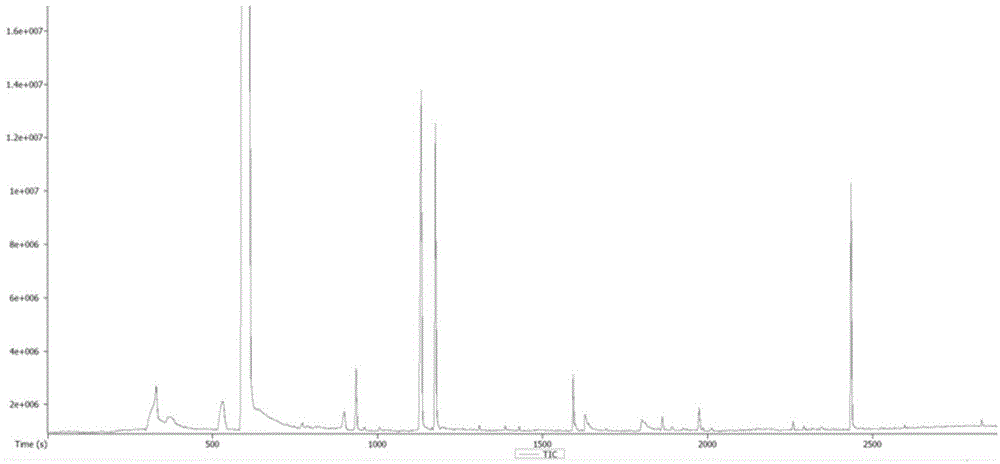

Image

Examples

Embodiment 1

[0027] In this embodiment, Jiuyunchun wine is prepared by semi-solid fermentation according to the following steps:

[0028] (1) Select 5 kg of high-quality rice and 1 kg of glutinous rice, wash them separately, soak the glutinous rice in water for 3 hours, and soak the rice in water for 1 hour, and cook until the rice grains are cooked and loose without white heart, and then rice and glutinous rice are obtained;

[0029] (2) Disperse and mix the steamed rice and glutinous rice with a rice loosening machine so as not to form a ball, spread it on the balcony and reduce the product temperature to 28°C to obtain 10kg of steamed rice ingredients;

[0030] (3) Add Xiaoqu and compound yeast liquid in the steamed rice material as a catalyst, stir evenly, and obtain the seasoning unstrained spirits; wherein: the total mass of Xiaoqu and compound yeast liquid is 4% of the quality of the steamed rice material; the quality of Xiaoqu and the compound yeast The ratio of the volume of the b...

Embodiment 2

[0035] In this embodiment, Jiuyunchun wine is prepared by liquid fermentation according to the following steps:

[0036] (1) Choose 5kg of high-quality rice and 2kg of glutinous rice as raw materials, crush and mix them, add 4 times the volume of warm water (80°C), put them in a stainless steel bucket, soak for 1h, and then gelatinize in a sterilizing pot at 110°C for 2h; Lower the temperature to 90°C and add amylase (2000U / g) accounting for 2% of the mass of the raw material, then incubate and hydrolyze at 88-90°C for 2 hours; lower the temperature to 60°C again and add glucoamylase (50000U / g) accounting for 1.5% of the mass of the raw material , heat preservation and saccharification for 2 hours to obtain rice milk;

[0037] (2) Regulate the sugar content of rice milk to 20BX to obtain the fermentation stock solution;

[0038] (3) Measure 10L of fermentation stock solution and cool it to 28°C, put it into a cleaned 50L pottery jar, add 30g of Xiaoqu and 20mL of compound yea...

Embodiment 3

[0043] In this embodiment, Jiuyunchun wine is prepared by liquid fermentation according to the following steps:

[0044] (1) Use 3kg of high-quality rice and 2kg of glutinous rice as raw materials, crush and mix them, add 4 times the volume of warm water (80°C), put them in a stainless steel bucket, soak for 1h, and then gelatinize in a sterilizing pot at 110°C for 1.5h ; Cool down to 90°C and add amylase (2000U / g) accounting for 2% of the mass of raw material, then insulate and hydrolyze at 88-90°C for 2 hours; cool down to 60°C again and add glucoamylase (50000U / g) accounting for 1.5% of the mass of raw material ), insulation and saccharification for 2h to obtain rice milk;

[0045] (2) adjust the sugar content of the rice milk to 21BX to obtain the fermentation stock solution;

[0046] (3) Measure 5L of fermentation stock solution and cool it to 28°C, put it into a cleaned 50L pottery jar, add 15g of Xiaoqu and 10mL of compound yeast liquid, and stir evenly; The ratio is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com