A method for making chafing dish fuel by using gutter oil as raw material

A waste oil and fuel technology, applied in the fuel, solid fuel, petroleum industry, etc., can solve the problems of high processing cost, complex process, environmental pollution of waste oil, etc., to improve output and quality, simple treatment process, and improve combustion firepower Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for making chafing dish fuel with waste oil as raw material, comprising the following steps:

[0030] (1) Mix waste oil and alcohol in equal volumes, put it into a heater and heat it to a temperature of 45°C, keep the temperature constant, and then add 11ml of sodium hydroxide solution for every 20ml of waste oil, wherein the sodium hydroxide solution The mass fraction of the sodium hydroxide is 45%; and the stirrer is used to continuously stir the treatment, and the stirring speed is 60r / min. After the stirring treatment time reaches 30min, then add vinegar accounting for 0.5% of the volume of sodium hydroxide to it, continue the heat treatment, and wait for the reaction After the time reaches 3 hours, place it in cold water for 40 minutes in a cold water bath, then add 30ml of hot water for every 20ml of waste oil, the temperature of the hot water is 45°C, and stir for 5 minutes at a stirring speed of 60r / min. Continue to put it into the cold water bath for c...

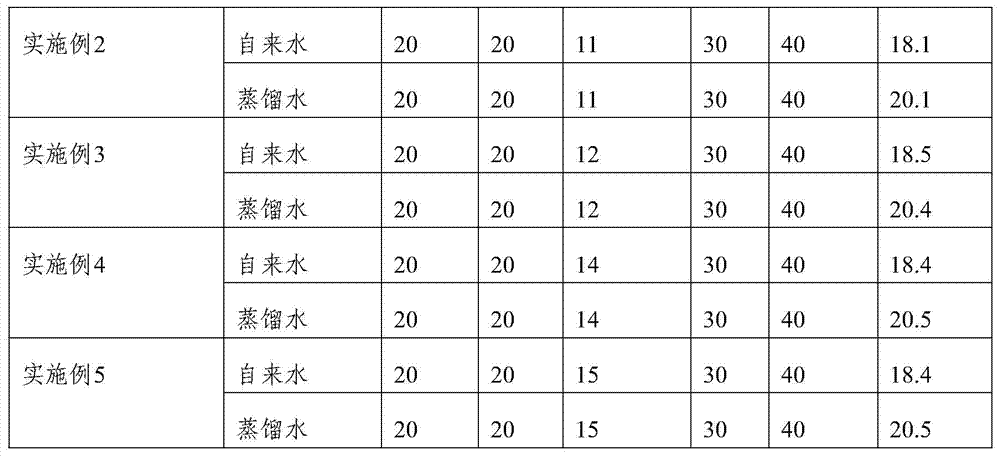

Embodiment 2

[0033] A method for making chafing dish fuel with waste oil as raw material, comprising the following steps:

[0034] (1) Mix waste oil and alcohol in equal volumes, put it into a heater and heat it to a temperature of 55°C, keep the temperature constant, and then add 14ml of sodium hydroxide solution for every 20ml of waste oil, wherein the sodium hydroxide solution The mass fraction of the sodium hydroxide is 55%; and the stirrer is used to continuously stir the treatment, and the stirring speed is 90r / min. After the stirring treatment time reaches 50min, then add vinegar accounting for 1% of the volume of sodium hydroxide to it, continue the heat treatment, and wait for the reaction After the time reaches 5 hours, place it in cold water for 70 minutes in a cold water bath, then add 30ml of hot water for every 20ml of waste oil, the temperature of the hot water is 50°C, and stir for 10min at a stirring speed of 80r / min. Continue to put it into the cold water bath for cooling...

Embodiment 3

[0037] A method for making chafing dish fuel with waste oil as raw material, comprising the following steps:

[0038] (1) Mix waste oil and alcohol in equal volumes, put it into a heater and heat it to a temperature of 50°C, keep the temperature constant, and then add 12ml of sodium hydroxide solution for every 20ml of waste oil, wherein the sodium hydroxide solution The mass fraction of the sodium hydroxide is 50%; and the stirrer is used to continuously stir the treatment, the stirring speed is 70r / min, after the stirring treatment time reaches 40min, then add vinegar which accounts for 0.7% of the volume of sodium hydroxide to it, continue the heat treatment, and wait for the reaction After the time reaches 4 hours, place it in cold water for 60 minutes in a cold water bath, then add 30ml of hot water for every 20ml of waste oil, the temperature of the hot water is 50°C, and stir for 9 minutes at a stirring speed of 70r / min. Continue to put it into the cold water bath for c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com