Flexible controlled-release microsphere disperse system formed by natural water-soluble polymer and preparation thereof and application of system in reinforcement of oil extraction

A technology of water-soluble polymers and dispersion systems, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve problems such as poor biodegradability and hidden dangers in application, achieve good stability, reduce oil-water interfacial tension, and improve The effect of recovery factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A flexible controlled-release microsphere dispersion system formed by a natural water-soluble polymer, including an aqueous solution of a natural water-soluble polymer containing carboxyl and hydroxyl groups, an aqueous solution of an inorganic salt, and an octane emulsion dispersed by a surfactant;

[0044] The surfactant-dispersed octane emulsion is obtained by adding octane to an aqueous surfactant solution and dispersing it uniformly;

[0045] The mass ratio of the natural water-soluble polymer aqueous solution containing carboxyl and hydroxyl groups, inorganic salt solution and surfactant-dispersed octane emulsion is 12:50:2.4;

[0046]The mass concentration of the described natural water-soluble polymer aqueous solution is 0.6%, the concentration of the described inorganic salt solution is 8000ppm, the mass concentration of the described surfactant aqueous solution is 0.1%, and the described surfactant aqueous solution and octane The mass ratio of alkane is 2:1; ...

experiment example 1

[0055] The flexible controlled-release microspheres prepared in Example 1 were placed in a flowing mineralized aqueous solution with a salinity of 2000ppm, the temperature of the constant mineralized water was 40°C, and the formation environment was simulated to observe the size change of the flexible controlled-release microspheres and degradation.

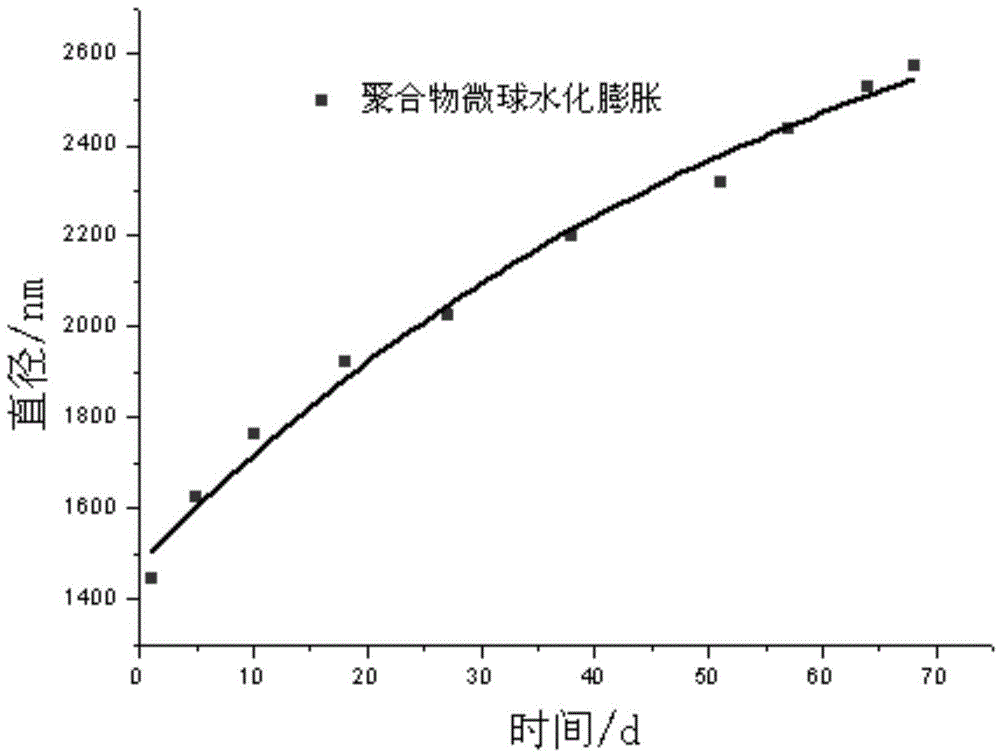

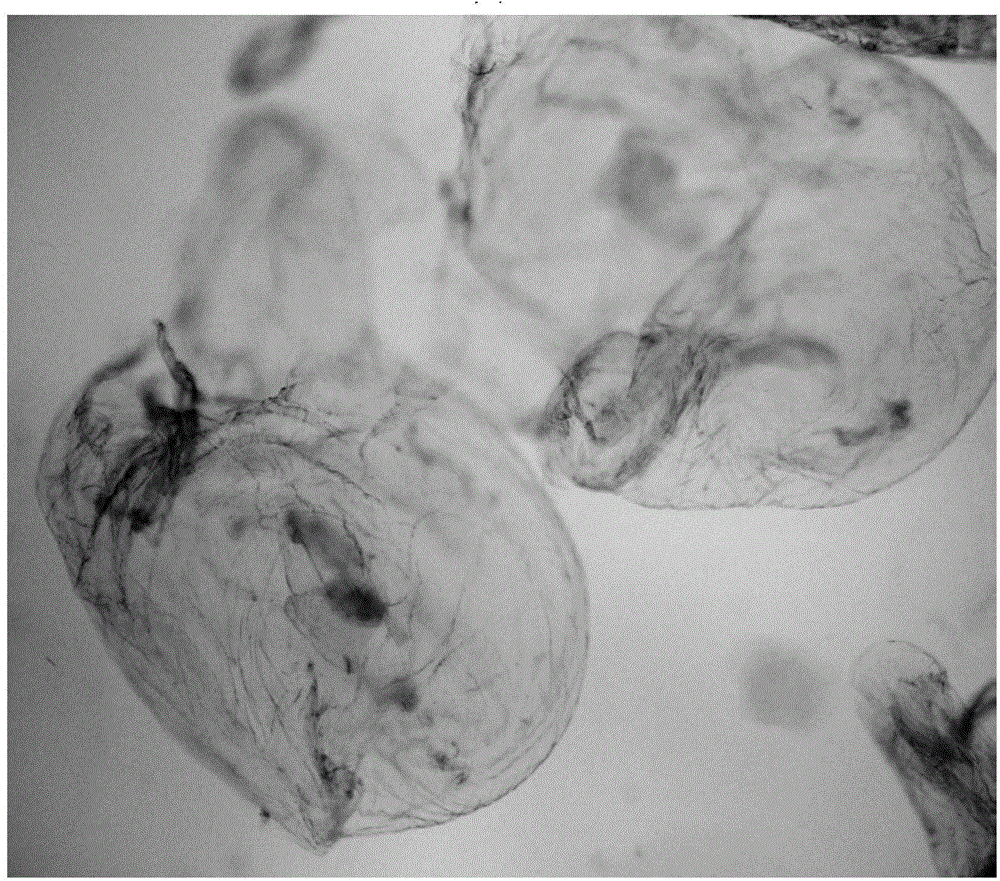

[0056] The hydration expansion law of the flexible controlled-release microspheres in the process of free migration in the formation was monitored by a microscope, and the size of the flexible controlled-release microspheres changed with time as follows: figure 1 shown. From figure 1 It can be seen that, with the increase of time, the flexible controlled-release microspheres gradually expanded. Therefore, during the formation migration process, the flexible controlled-release microspheres will hydrate and expand until the plugging effect occurs.

[0057] After 300 days, the flexible controlled-release microspheres ruptured and...

experiment example 2

[0059] In Experimental Example 1, the surfactant will be released gradually during the expansion process of the flexible controlled-release microspheres. The external solution of the flexible controlled-release microspheres was collected by filtration, and the ability of the released surfactant to reduce the interfacial tension was measured by a spinning drop interfacial tensiometer. The model of the interfacial tensiometer used is TEXAS-500, and the experimental temperature is adjusted to 50°C. The oil phase used is Shengtuokou Outer Oil, and the rotational speed is adjusted to 6000r / min. It was found that the surfactant released by the flexible controlled-release microspheres Can reduce the oil-water interfacial tension to 10 within 15 minutes -2 mN.m -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com