Preparing method of graphene/waterborne polyurethane composite material

A technology of water-based polyurethane and composite materials, which is applied in the field of preparation of graphene/water-based polyurethane composite materials, can solve the problems of unsuitability for large-scale industrial production and complicated processes, and achieve good heat resistance, good compatibility, and good water Dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

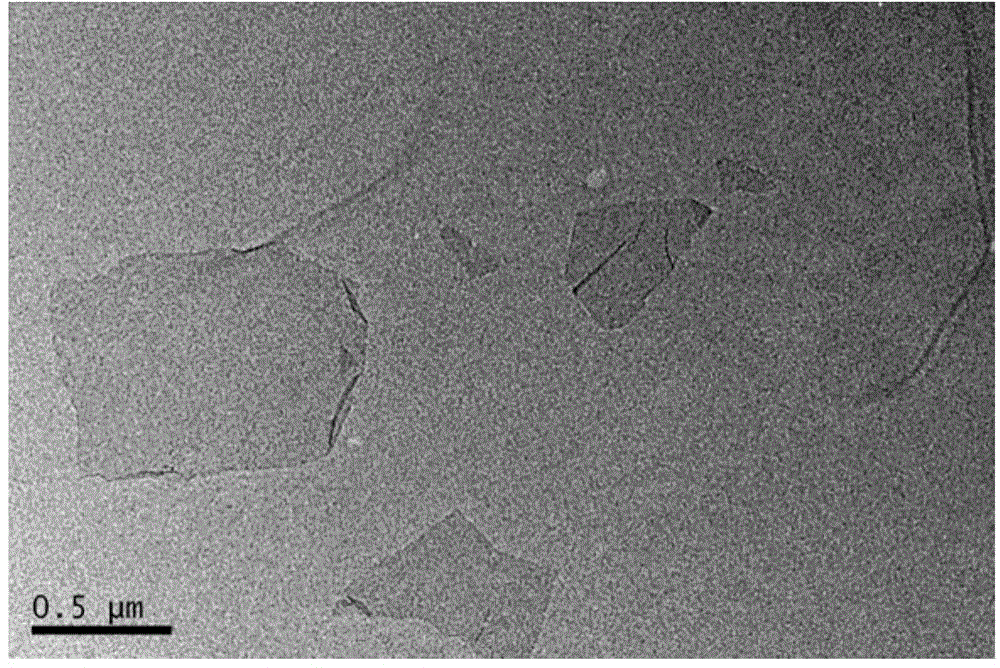

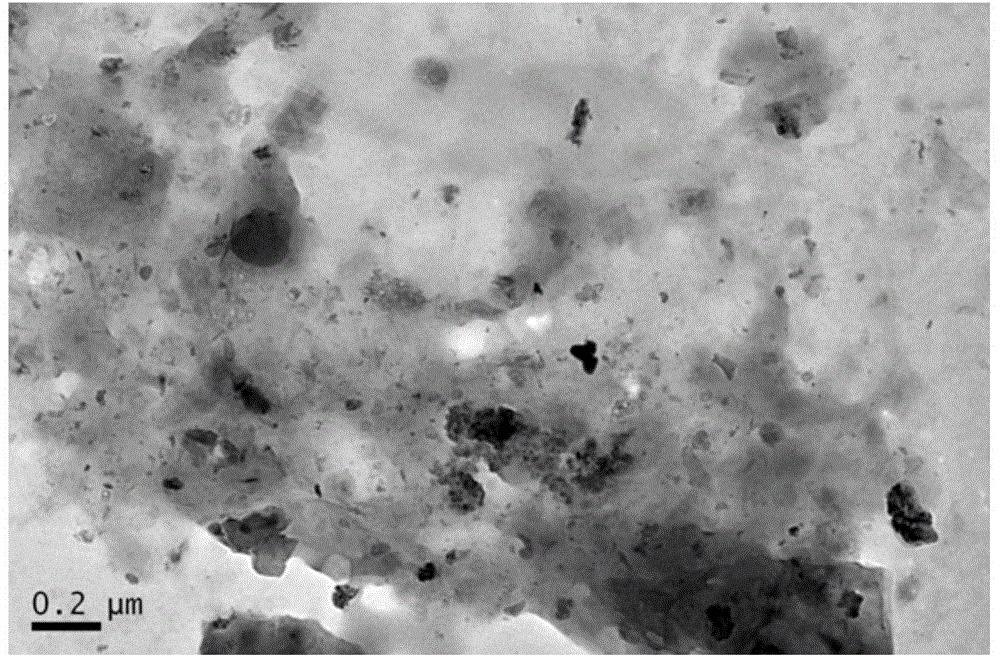

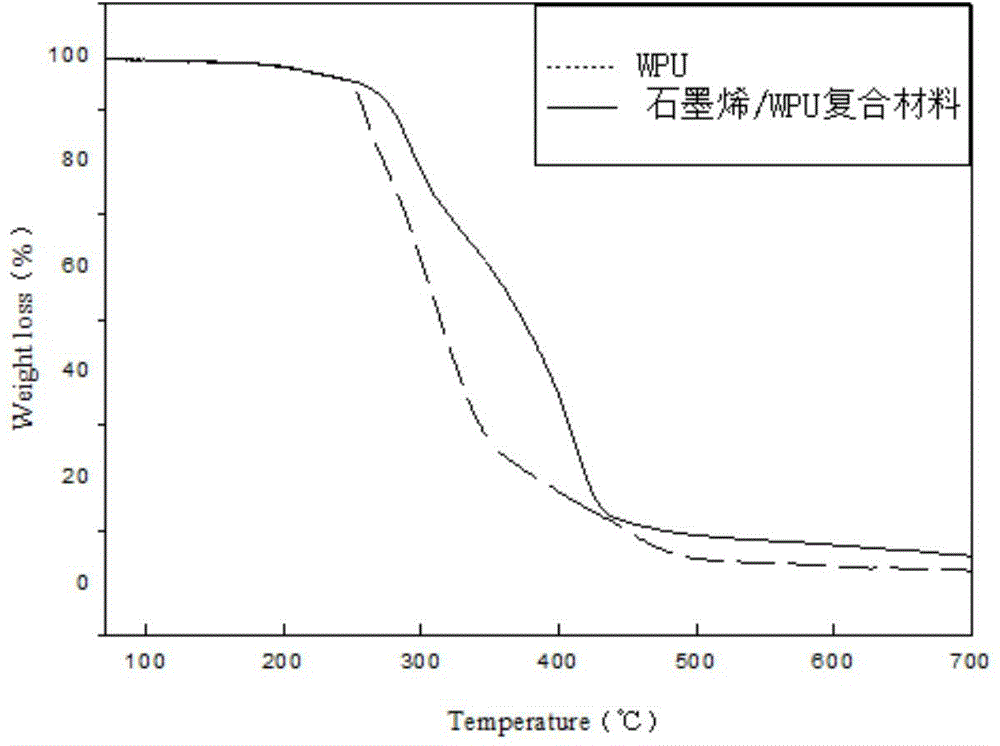

Image

Examples

Embodiment 1

[0037] The present embodiment prepares graphene / waterborne polyurethane composite material according to the following steps:

[0038] 1. Preparation of graphene oxide

[0039] Graphite (3.0g), H 2 SO4 (70 mL), NaNO 3 (1.5g) was mixed in a 250mL Erlenmeyer flask under an ice-water bath, stirred evenly by magnetic force, slowly added potassium permanganate (9.0g) and continued to stir in an ice-water bath for 2 hours, and then stirred overnight at 35°C Slowly add 100mL deionized water to stir and dilute; then transfer to a 1000mL beaker, add distilled water to dilute to obtain a mixed solution; slowly stir and add 20mL 30% hydrogen peroxide dropwise to the mixed solution until the color of the mixed solution turns golden yellow, Stand still until the foam disappears, stir and add 200mL, 1.0mol / L HCl solution, and stand still to obtain a precipitate. The precipitate is centrifuged and washed repeatedly, and washed several times to weak acidity, that is, graphite oxide.

[004...

Embodiment 2

[0054] The present embodiment prepares graphene / waterborne polyurethane composite material according to the following steps:

[0055] 1. Preparation of graphene oxide

[0056] Graphite (3.0g), H 2 SO 4 (70 mL), NaNO 3 (1.5g) was mixed in a 250mL Erlenmeyer flask under an ice-water bath, stirred evenly by magnetic force, slowly added potassium permanganate (9.0g) and continued to stir in an ice-water bath for 2 hours, and then stirred overnight at 35°C Slowly add 100mL deionized water to stir and dilute; then transfer to a 1000mL beaker, add distilled water to dilute to obtain a mixed solution; slowly stir and add 20mL 30% hydrogen peroxide dropwise to the mixed solution until the color of the mixed solution turns golden yellow, statically Set aside until the foam disappears, stir and add 200mL, 1.0mol / L HCl solution, and let it stand still to obtain a precipitate. The precipitate is centrifuged and washed repeatedly, and washed several times to weak acidity, that is, graph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com