Conductive high-molecular composite material with dendritic cellular structure, and preparation method thereof

A conductive polymer and composite material technology, applied in the field of conductive polymer composite materials, can solve problems such as hindering popularization and application, strong polymer selectivity, complex operation process, etc., and achieve easy popularization and application, stable electrical performance, and wide sources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The second technical problem to be solved in the present invention is to provide the preparation method of the above-mentioned conductive polymer composite material, the steps include:

[0044] a. Preparation of the mixed solution: dissolving and mixing the thermoplastic elastomer material, thermosetting resin, curing agent and conductive particles in a solvent to obtain a mixed solution;

[0045] b. Freeze-drying: the mixed solution obtained in step a is freeze-dried to obtain the conductive polymer composite material;

[0046] Wherein, the solvent is at least one of dioxane, water, acetone, toluene, xylene, tetrahydrofuran, dimethylformamide, methanol, ethanol, formic acid or methylene chloride; the amount of solvent is: per weight 20-100ml of solvent is added to one part of raw materials, namely thermoplastic elastomer material, thermosetting resin, curing agent and conductive particles.

[0047] Further, in the preparation method of the above-mentioned conductive c...

Embodiment 1

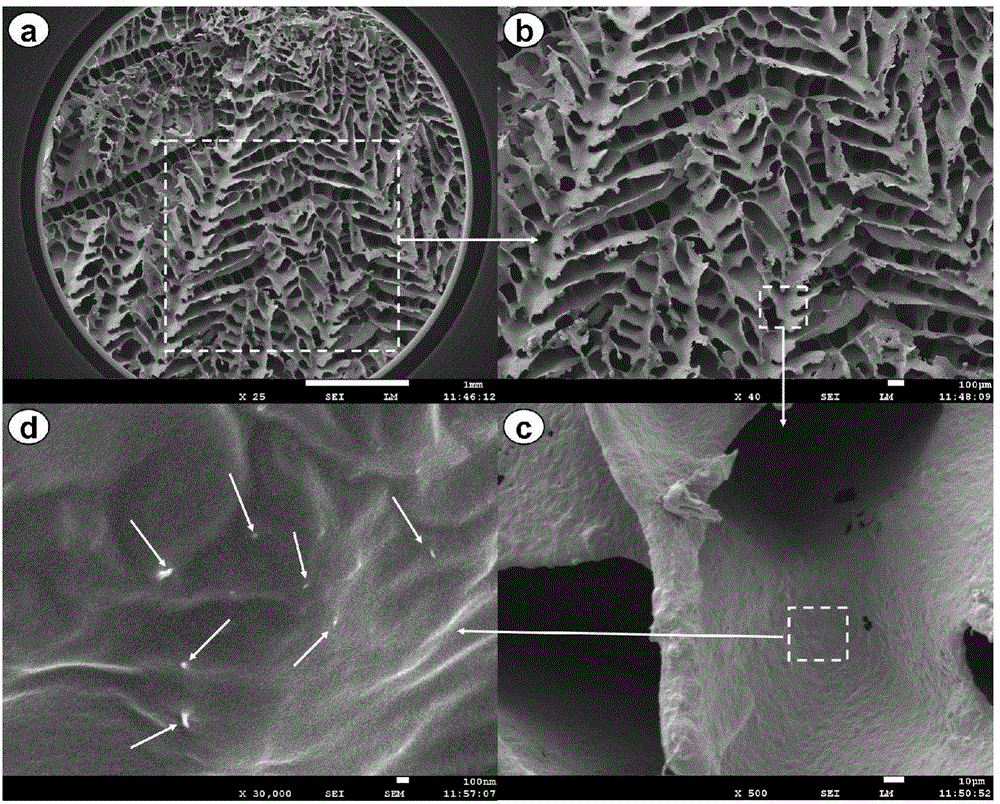

[0056] Example 1 Preparation of Conductive Polymer Composite Material with Dendritic Cell Structure

[0057] Concrete preparation steps are:

[0058] (1) Drying of raw materials: Dry TPU and MWCNTs in a vacuum oven for 8 hours at 80°C;

[0059] (2) Preparation of mixed solution: 1.2g epoxy resin (model: epoxy resin LT5078A), 0.4g curing agent (model: curing agent LT5078B), and 0.44g MWCNTs were added to 40ml of dioxane in sequence respectively. In a 100ml beaker, stir mechanically at room temperature for about 10 minutes, then ultrasonically disperse in a water bath at room temperature for 30 minutes to obtain a mixed solution a; at the same time, mix 2.4g of TPU pellets and 40ml of dioxane in a 100ml beaker, and heat Stir, the temperature is at 50°C, stir magnetically for about 1 hour, cool to room temperature, and obtain mixed solution b; then pour mixed solution b into mixed solution a, and magnetically stir for 30 minutes to obtain the final MWCNTs / TPU / epoxy resin / Curin...

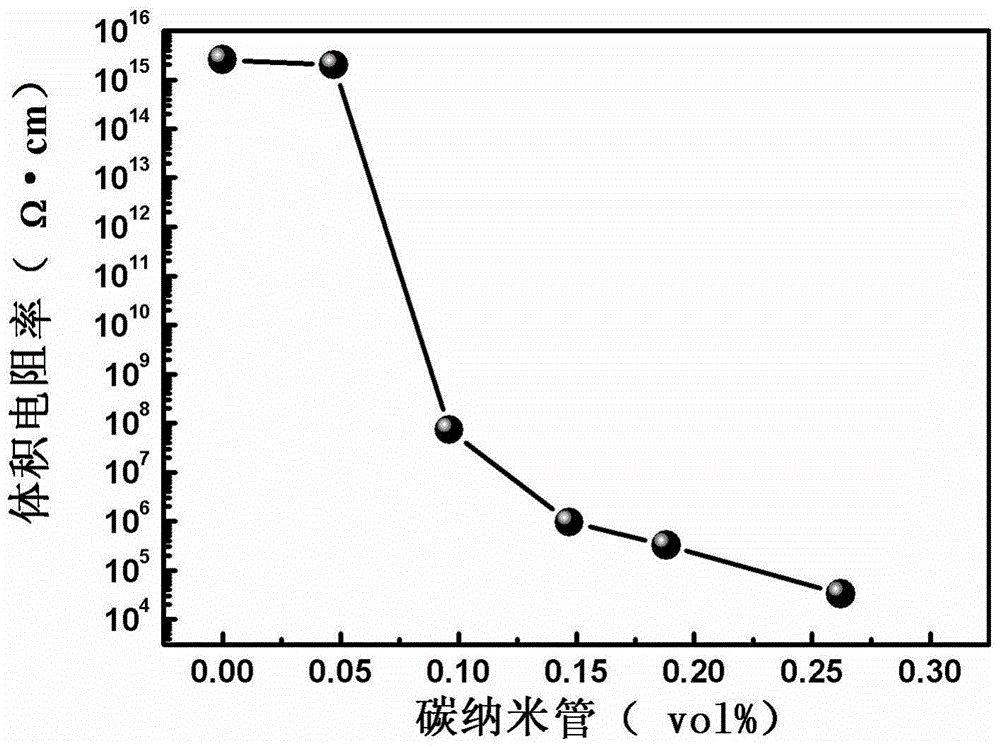

Embodiment 2-6

[0063] Example 2-6 Preparation of Conductive Polymer Composite Material with Dendritic Cell Structure

[0064] Each raw material ratio of embodiment 2-6 is as shown in table 1. The specific preparation methods are all the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com