A kind of preparation method of mercapto-ene polymer flame retardant system

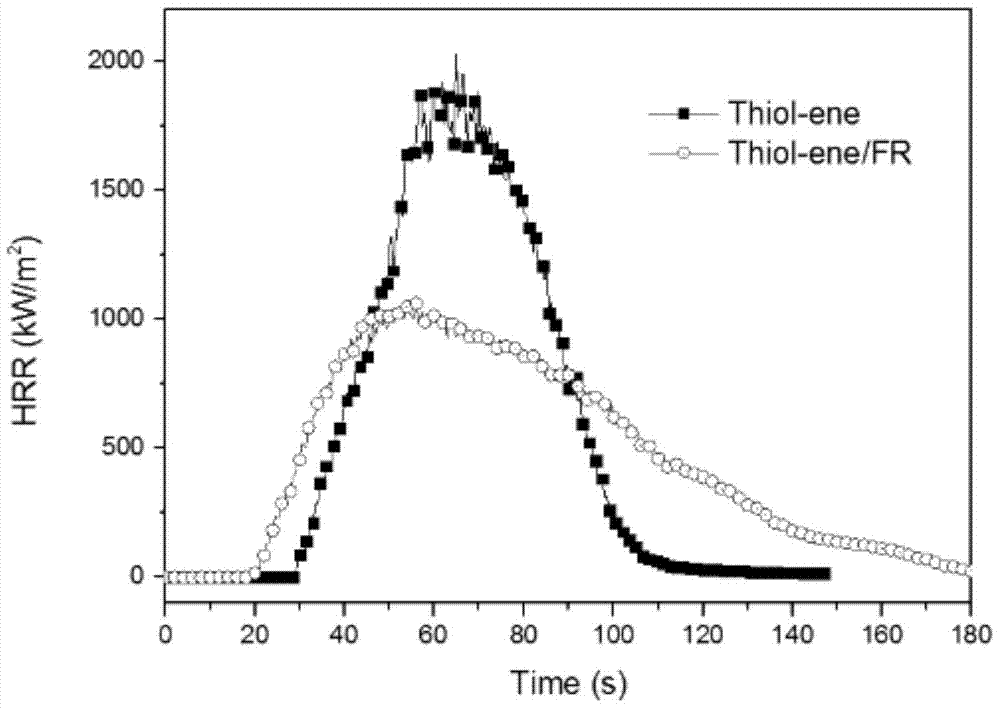

A technology of mercapto compounds and polymers, which is applied in the field of preparation of mercapto-ene polymer flame retardant systems, can solve problems such as flame retardant and heat resistance defects, and achieve the effects of being environmentally friendly, harmless and structurally stable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation method of mercapto-ene polymer flame retardant system in the present embodiment comprises the following steps:

[0034] (1) Preparation of polysiloxane

[0035] Measure 15mL of ethanol and 5mL of deionized water, add 0.2g of aminopropyltriethoxysilane, 0.2g of vinyltrimethoxysilane, and 2g of phenyltrimethoxysilane, and stir well; slowly add four Methylammonium hydroxide, control the pH value of the reaction solution to 8, stir and react at room temperature for 4h; after the reaction is completed, collect the product through a rotary evaporator, and finally dry it in vacuum at room temperature to obtain polysiloxane containing amino, vinyl, and phenyl alkyl;

[0036] (2) Carbon nanotube grafted polysiloxane

[0037] Mix 200 mg of carboxylated multi-walled carbon nanotubes with 20 mL of thionyl chloride and 1 mL of DMF, and perform ultrasonic treatment to fully disperse the carbon nanotubes into the solution, and react for 24 hours under magnetic stirri...

Embodiment 2

[0043] The preparation method of mercapto-ene polymer flame retardant system in the present embodiment comprises the following steps:

[0044] (1) Preparation of polysiloxane

[0045] Measure 30mL of ethanol and 10mL of deionized water, add 0.5g of aminopropyltrimethoxysilane, 0.2g of vinylmethyldimethoxysilane, and 1g of phenyltrimethoxysilane, and stir well; Add tetraethylammonium hydroxide, control the pH value of the reaction solution to 10, and stir the reaction at room temperature for 6 hours; after the reaction is completed, the product is collected by a rotary evaporator, and finally vacuum-dried at room temperature to obtain a polyamide containing amino groups, vinyl groups, and phenyl groups. Silicone;

[0046] (2) Carbon nanotube grafted polysiloxane

[0047] Mix 200 mg of carboxylated multi-walled carbon nanotubes with 20 mL of thionyl chloride and 1 mL of DMF and perform ultrasonic treatment to fully disperse the carbon nanotubes into the solution, and react for 3...

Embodiment 3

[0052] The preparation method of mercapto-ene polymer flame retardant system in the present embodiment comprises the following steps:

[0053] (1) Preparation of polysiloxane

[0054] Measure 30mL of ethanol and 10mL of deionized water, add 0.5g of aminopropyltrimethoxysilane, 0.2g of vinylmethyldimethoxysilane, and 1g of phenyltrimethoxysilane, and stir well; Add tetrabutylammonium hydroxide, control the pH value of the reaction solution to 10, and stir the reaction at room temperature for 6 hours; after the reaction is completed, collect the product through a rotary evaporator, and finally dry it in vacuum at room temperature to obtain polysiloxane containing amino, vinyl, and phenyl groups. alkyl;

[0055] (2) Carbon nanotube grafted polysiloxane

[0056] Mix 200 mg of carboxylated multi-walled carbon nanotubes with 20 mL of thionyl chloride and 1 mL of DMF and perform ultrasonic treatment to fully disperse the carbon nanotubes into the solution, and react for 30 h under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com