A device and method for continuous production of polyoxydimethyl ether

A polyoxydimethyl ether and paraformaldehyde technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as failure to achieve substantial breakthroughs, and achieve wide adaptability and shortened reactions. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

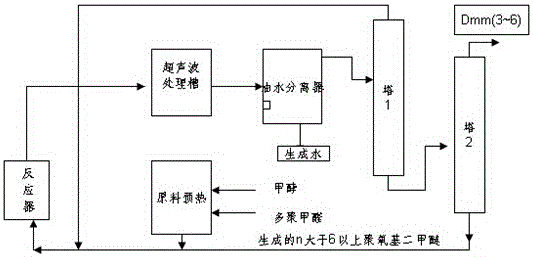

Image

Examples

Embodiment 1

[0047] According to this technology, methanol and paraformaldehyde are fed at a ratio of 1:1, respectively 2.5 tons, and CH 3 (CH 2 O) 3-5 OCH 3 Mixed products. A 0.5-ton interlayer reactor is used, the heating method is electric heating rod heat-conducting oil, the operating temperature is 120°C, and the pressure is 0.15Mpa; the later refining adopts double towers and normal pressure. Catalyst preparation: 355kg of 98% sulfuric acid, 295kg of 85% phosphoric acid.

[0048] Specific steps:

[0049] 1. After the final inspection of equipment function, performance and safety status is completed, the prepared multifunctional catalyst is added to the reactor at one time, and the pressure stabilization, pressure maintenance and pressure relief valves of the reactor are adjusted to 0.15Mpa, and nitrogen is sealed.

[0050] 2. Send electricity to heat up to the set temperature and keep it relatively stable.

[0051] 3. According to the set flow rate, start to evenly feed materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com