A production method for producing autoclaved lime-sand bricks from copper tailings

An autoclaved lime-sand brick and production method technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of high utilization cost and inappropriateness, and achieve large production capacity and high work efficiency , ingeniously designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

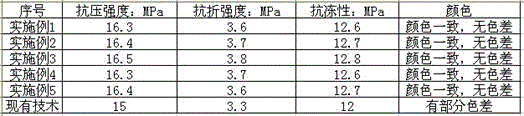

Examples

Embodiment 1

[0014] Example 1 : A kind of production method of producing autoclaved lime-sand brick with copper tailings, according to mass percentage, described copper ore tailings sand content is 36%, carbide slag 10%, stone dust 20%, fine sand 34%, wherein carbide slag The effective calcium oxide content is ≥65%, the silica content of copper ore tailings is ≥35%, the moisture content of stone chips is ≤3%, and the moisture content of fine sand is ≤7%; the fineness and particle size of the copper ore tailings are as follows, The particle size ≤ 10 μm accounts for 100%, of which the particle size ≤ 2.0 μm accounts for 50%, and the moisture content is 18%. The particle size of the stone chips and fine sand is 0.10mm-3.0mm; the method is as follows, 1) Copper ore Tailings sand pretreatment: Spread the wet and agglomerated tailings sludge transported to the stockyard to dry, and collect them for later use when the moisture content drops below 17%. The tailings sand is transported to the ma...

Embodiment 2

[0015] Example 2 : A kind of production method of producing autoclaved lime-sand brick with copper tailings, according to mass percentage, described copper ore tailings sand content is 38%, carbide slag 11%, stone dust 18%, fine sand 33%, wherein calcium carbide slag The effective calcium oxide content is ≥65%, the silica content of copper ore tailings is ≥35%, the moisture content of stone chips is ≤3%, and the moisture content of fine sand is ≤7%; the fineness and particle size of the copper ore tailings are as follows, The particle size ≤ 10 μm accounts for 100%, of which the particle size ≤ 2.0 μm accounts for 50%, the water content is 18%-23%, and the particle size of the stone chips and fine sand is 0.10mm-3.0mm. The method is as follows: 1) Copper ore tailing sand pretreatment: spread out the wet and agglomerated tailing mud transported to the stockyard to dry, and collect it for later use when the moisture content drops below 17%; 2) Put stone chips and carbide slag ...

Embodiment 3

[0016] Example 3: A kind of production method of producing autoclaved lime-sand brick with copper tailings, according to mass percentage, described copper ore tailings sand content is 40%, carbide slag 12%, stone dust 16%, fine sand 32%, wherein carbide slag The effective calcium oxide content is ≥65%, the silica content of copper ore tailings is ≥35%, the moisture content of stone chips is ≤3%, and the moisture content of fine sand is ≤7%; the fineness and particle size of the copper ore tailings are as follows, The particle size ≤ 10 μm accounts for 100%, of which the particle size ≤ 2.0 μm accounts for 50%, the water content is 18%-23%, and the particle size of the stone chips and fine sand is 0.10mm-3.0mm. The method is as follows: 1) Copper ore tailing sand pretreatment: spread out the wet and agglomerated tailing mud transported to the stockyard to dry, and collect it for later use when the moisture content drops below 17%; 2) Put stone chips and carbide slag , fine sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com