Preparation method of chitosan modified starch impregnating compound

A starch-type sizing agent and chitosan modification technology, which is applied in the preparation of chitosan-modified starch-type sizing agent and the field of sizing agent preparation, can solve the problem of chitosan-modified starch-type sizing agent, solid The human skin of the colorant has problems such as irritation and complicated preparation process, and achieves the effects of superior chemical and thermal stability, effective diffusion and spreading, and easy availability of raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

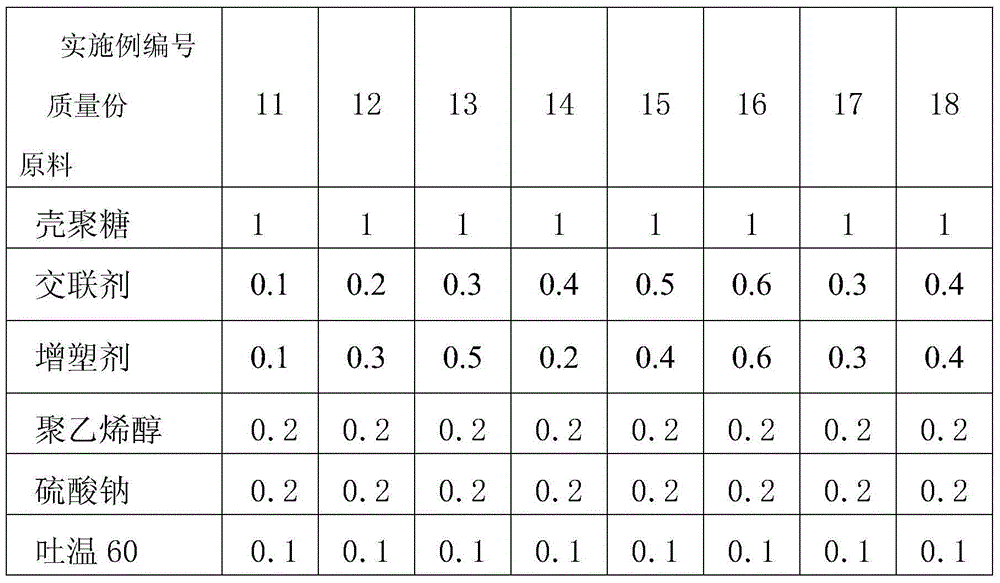

Examples

Embodiment 1

[0024] A kind of preparation method of chitosan modified starch type sizing agent, the steps are as follows:

[0025] a. Put 9 parts by mass of raw starch into a reaction container, add 300 parts by mass of water, heat up to 90° C. under stirring, and perform a gelatinization reaction for 1 hour to obtain a starch paste;

[0026] b, get 1 mass part of chitosan and join in the starch paste, and slowly add 0.2 mass part of crosslinking agent, 0.2 mass part of plasticizer, 0.2 mass part of polyvinyl alcohol, 0.2 mass part of Sodium sulfate, the Tween 60 of 0.1 mass part, obtains mixed material;

[0027] c. React the mixed material at 90° C. for 1 hour, cool to room temperature, let it stand for 2 hours, and defoam to obtain a chitosan-modified starch-type sizing agent.

Embodiment 2

[0029] A kind of preparation method of chitosan modified starch type sizing agent, the steps are as follows:

[0030] a. Put 12 parts by mass of raw starch into a reaction container, add 300 parts by mass of water, stir, heat up to 90° C., and perform a gelatinization reaction for 1 hour to obtain a starch paste;

[0031] b, get 1 mass part of chitosan and join in the starch paste, and slowly add 0.2 mass part of crosslinking agent, 0.2 mass part of plasticizer, 0.2 mass part of polyvinyl alcohol, 0.2 mass part of Sodium sulfate, the Tween 60 of 0.1 mass part, obtains mixed material;

[0032] c. React the mixed material at 90° C. for 1 hour, cool to room temperature, let it stand for 2 hours, and defoam to obtain a chitosan-modified starch-type sizing agent.

Embodiment 3

[0034] A kind of preparation method of chitosan modified starch type sizing agent, the steps are as follows:

[0035] a. Put 15 parts by mass of raw starch into a reaction container, add 300 parts by mass of water, stir, heat up to 90° C., and perform a gelatinization reaction for 1 hour to obtain a starch paste;

[0036] b, get 1 mass part of chitosan and join in the starch paste, and slowly add 0.2 mass part of crosslinking agent, 0.2 mass part of plasticizer, 0.2 mass part of polyvinyl alcohol, 0.2 mass part of Sodium sulfate, the Tween 60 of 0.1 mass part, obtains mixed material;

[0037] c. React the mixed material at 90° C. for 1 hour, cool to room temperature, let it stand for 2 hours, and defoam to obtain a chitosan-modified starch-type sizing agent.

[0038] The sizing performance test results of Examples 1, 2 and 3 are shown in Table 1 and Table 2 below:

[0039] Table 1: Performance parameters of the wetting agent prepared in Examples 1, 2 and 3

[0040] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com