Brake cooling method and brake cooling device

A technology of a cooling device and a cooling method, applied in the directions of brakes, cooling brakes, transportation and packaging, etc., can solve the problems of uneven thermal deformation, low cooling efficiency, affecting vehicle safety, etc., to avoid large temperature differences and improve cooling efficiency. , to avoid the effect of slippery road

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

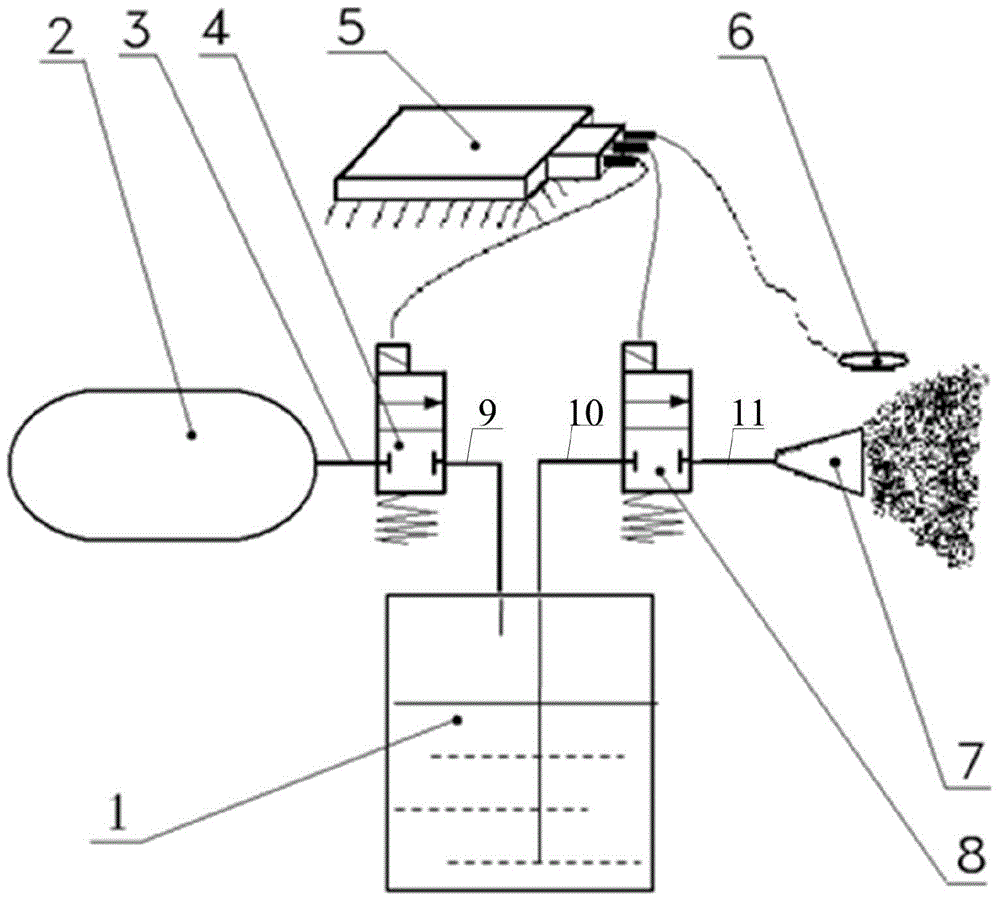

[0043] Please refer to figure 1 , figure 1 It is a schematic structural diagram of the brake cooling device provided in Embodiment 1 of the present invention, and the brake cooling device specifically includes:

[0044] Gas storage tank 2, used to store high-pressure gas;

[0045] It should be noted that the high-pressure gas stored in the air storage tank 2 refers to the air that can make the cooling water in the water tank 1 reach the spray nozzle 7 and be sprayed out. The specific value of the air pressure is not specified in this embodiment. Strictly limited, the same is true for other embodiments of the present invention;

[0046] One end is connected to the air storage tank 2, and the other end is connected to the first electromagnetic valve 4 of the water tank 1;

[0047] The water tank 1 with one end connected to the first electromagnetic valve 4 and the other end connected to the second electromagnetic valve 8;

[0048] What needs to be specially explained here is...

Embodiment 2

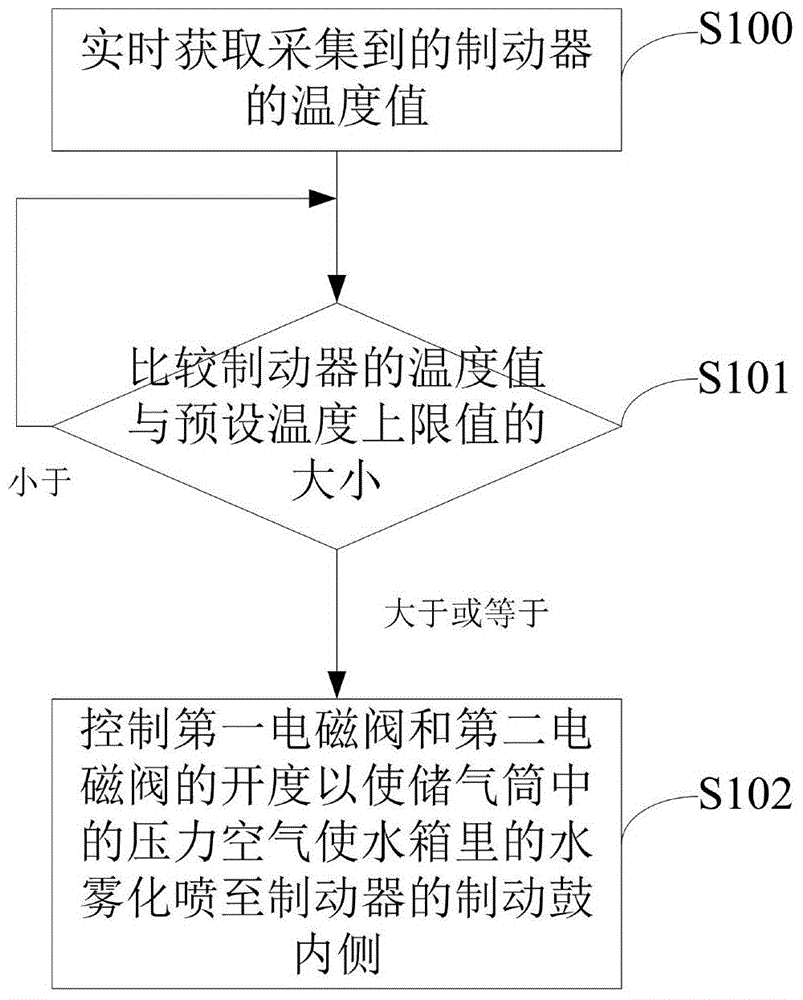

[0075] Based on the brake cooling device disclosed in the above embodiments and figure 1 The schematic diagram of the structure of the brake cooling device is shown, and the second embodiment of the present invention provides a corresponding brake cooling method, such as figure 2 Said, the method specifically includes the following steps:

[0076] Step S100, acquiring the collected temperature value of the brake in real time;

[0077] Specifically, the controller acquires the temperature value of the brake drum of the brake collected by the temperature collector 6 in real time;

[0078] It should be noted that the execution subject of the execution steps in each embodiment of the present invention is the controller, that is to say, unless otherwise specified, the execution steps in each embodiment are all completed by the controller;

[0079] Step S101, comparing the temperature value of the brake with the preset temperature upper limit value, and when the comparison result...

Embodiment 3

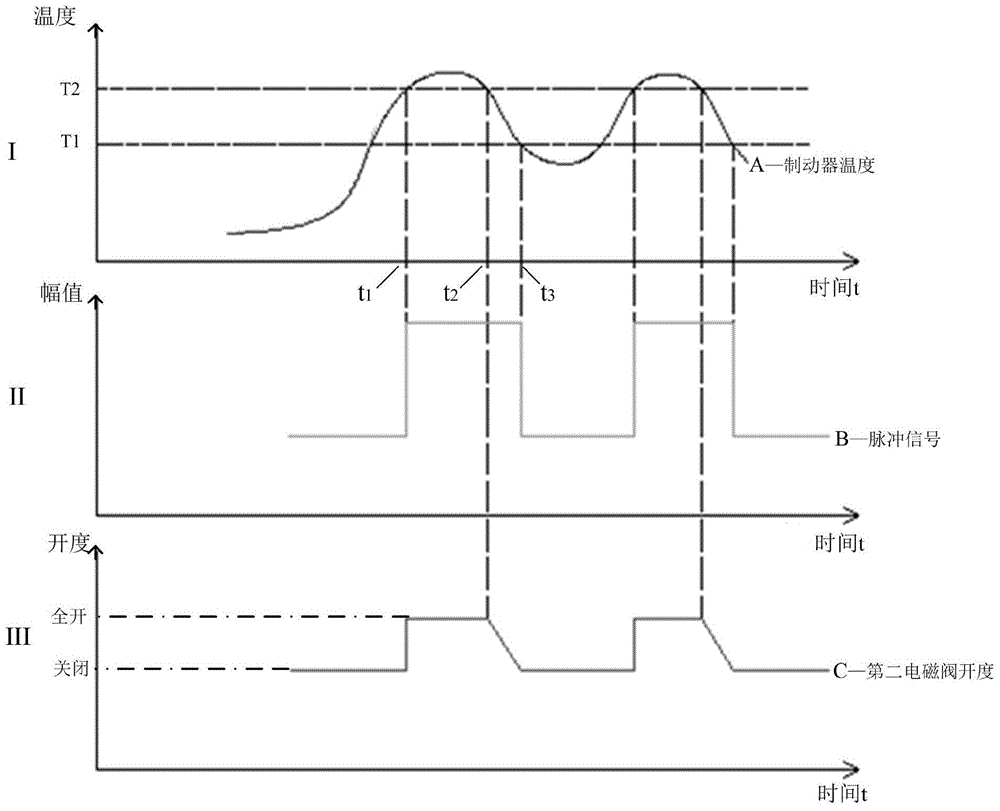

[0094] Based on the brake cooling method disclosed in the second embodiment above, it executes step S102, controlling the openings of the first electromagnetic valve 4 and the second electromagnetic valve 8 so that the pressure air in the air storage tank 2 makes the water in the water tank 1 The water is atomized and sprayed to the inner side of the brake drum of the brake through the spray nozzle 7, including:

[0095] Step S200, controlling the opening degree of the first solenoid valve 4 to be fully open, so that the pressurized gas in the air storage tank 2 enters the water tank 1;

[0096] Step S201, controlling the opening degree of the second solenoid valve 8 to be fully open, and performing a logical subtraction operation on the current temperature value of the brake and the preset temperature lower limit value, and according to the operation result obtained by the logical subtraction operation The opening degree of the second solenoid valve 8 is controlled to adjust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com