Plastic clamping buckle type safety air bag integrated with ringing structure

A technology for airbags and plastic cards, applied in vehicle safety arrangement, pedestrian/occupant safety arrangement, transportation and packaging, etc., can solve the problems of high material cost, low assembly efficiency, easy to produce abnormal noise, etc. Simple, noise-removing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

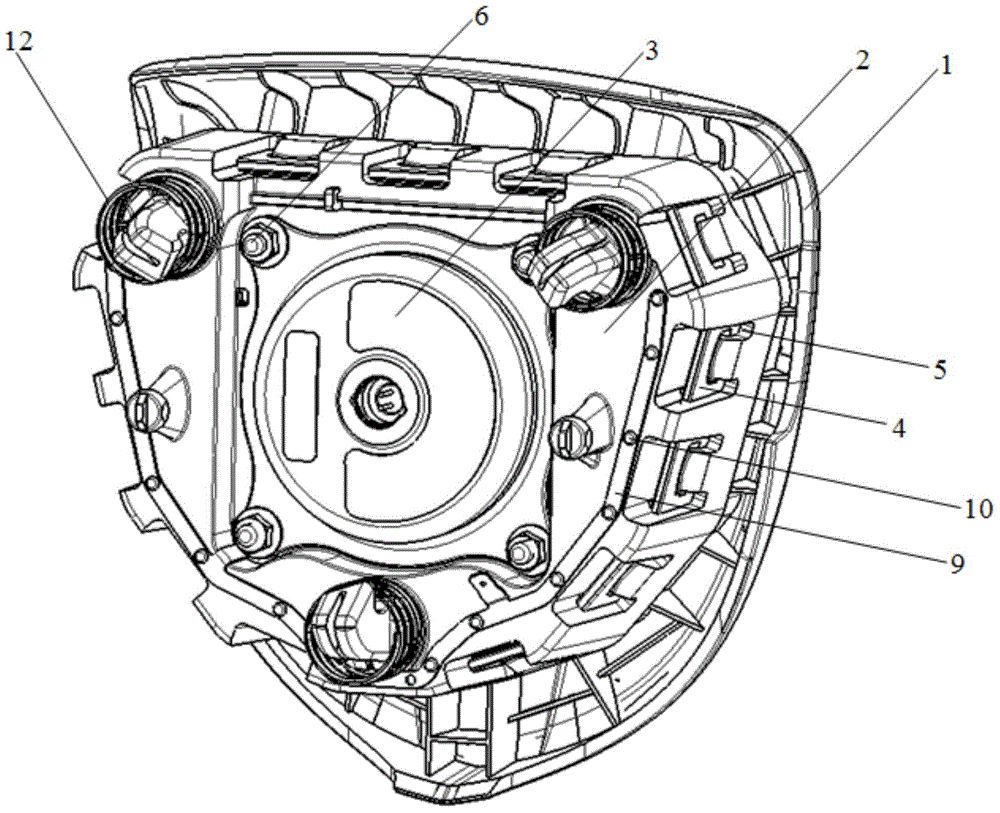

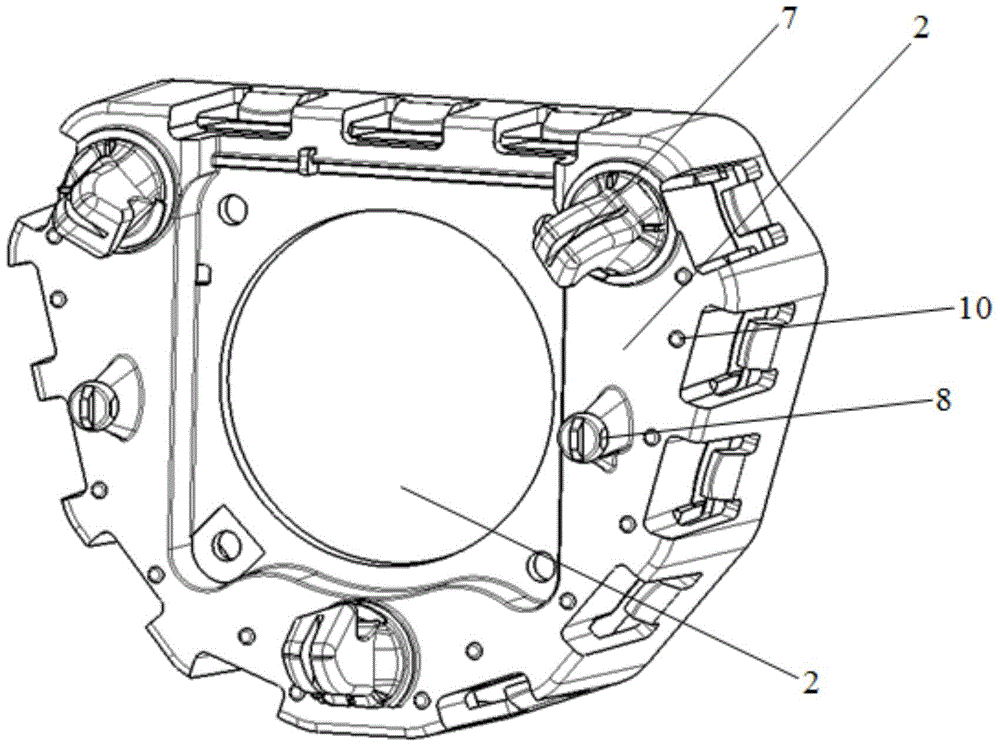

[0016] See attached Figure 1-2 As shown, a plastic buckle-type airbag integrating a click structure, it includes a cover plate 1, a housing 2 and a generator 3, the cover plate 1 is provided with an undercut 4, and the shell The body 2 is provided with a buckle groove 5 matching the undercut 4, and the undercut 4 is assembled into the buckle groove 5 to complete the fixed connection between the cover plate 1 and the housing 2; The generator 3 is fixed in the through hole 10 in the center of the housing 2 through the bolt 6; the housing 2 is injection molded from a plastic material, and the housing 2 is also provided with a hook 7 and a fixing column 8. Horn copper sheet 9, the hook 7 is used for assembly connection with the steering wheel, the fixed column 8 is used to limit the assembly position with the steering wheel, and the horn copper sheet 9 is heated by heat The melting column 11 is fixed on the shell 2 by heating.

[0017] In order to further optimize the airbag, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com