Method for preventing extracting mill frame driven shaft from shedding

A passive shaft and frame technology, applied in the direction of unloading mandrel, roll safety equipment, metal rolling, etc., can solve the problem that the frame cannot be pulled out, and achieve the effects of avoiding production stop accidents, increasing production, and simple and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The concrete steps of the method for preventing the passive shaft of the detached rack from falling off in the present invention are as follows:

[0019] 1. Make a protective frame

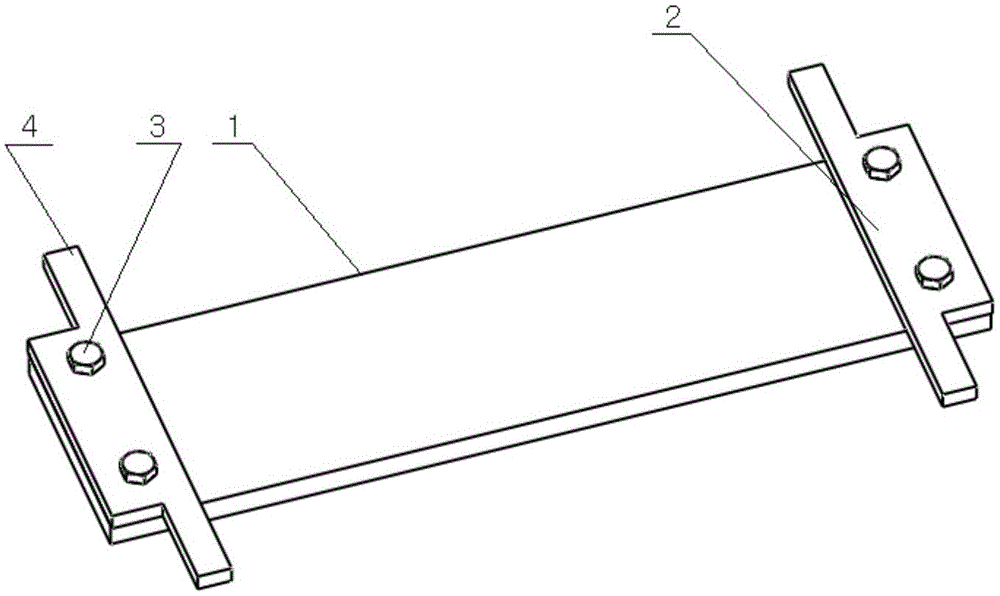

[0020] Depend on figure 1 It can be seen that the protective frame is composed of a baffle plate 1, a support plate 2 and a bolt 3. The size of the baffle plate 1 and the support plate 2 is designed according to the specific size of the groove 5 in the lower part of the frame 7. The baffle plate 1 is a rectangular plate with a length of 520mm, a width of 245mm, and a thickness of 26mm. Both ends of the baffle plate 1 are provided with bolt holes. The two support plates 2 are respectively vertically connected to the two ends of the baffle plate 1 through the bolts 3 , and at the same time, a protruding card platform 4 is respectively processed at the two ends of the two support plates 2 .

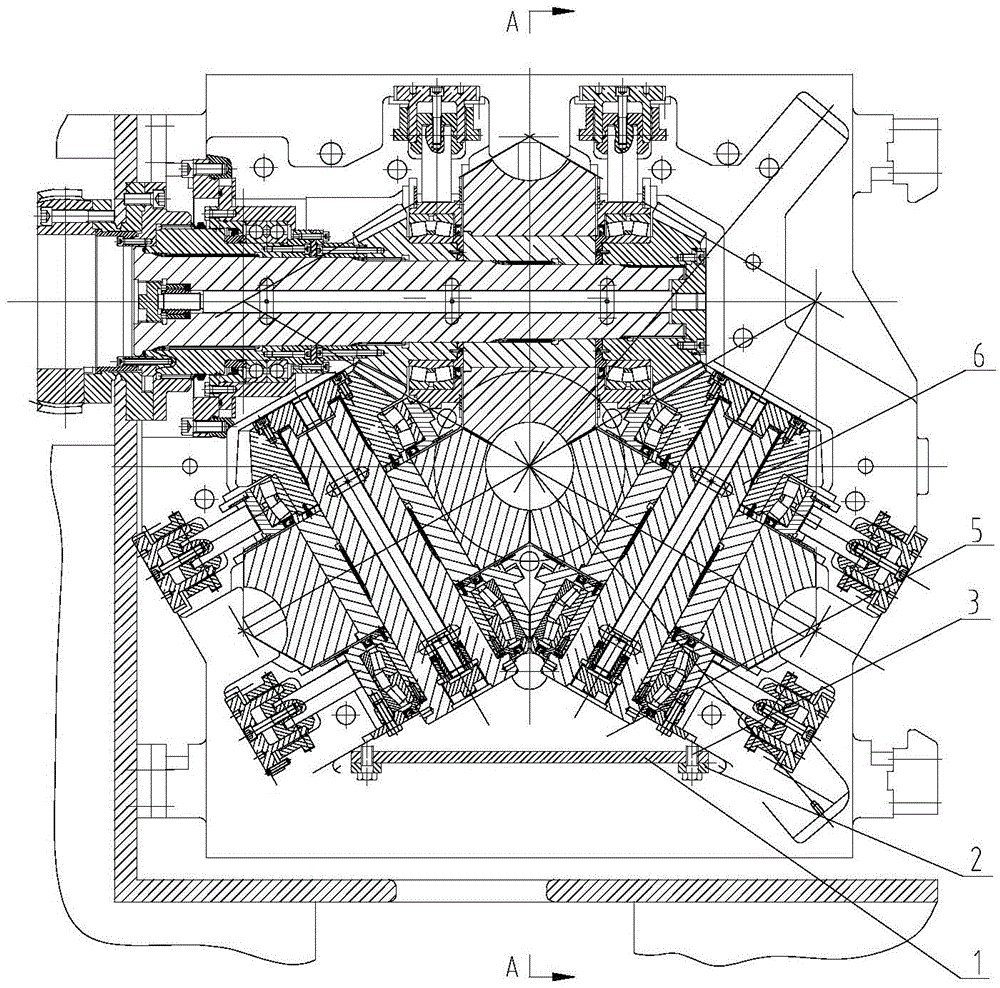

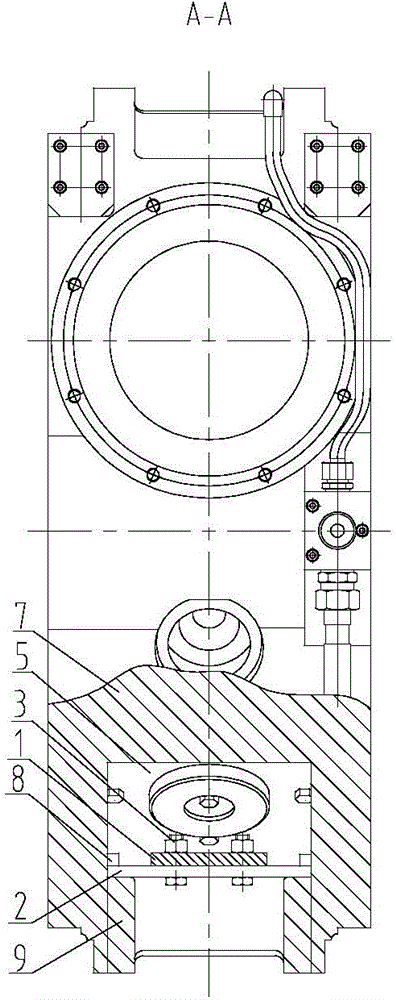

[0021] 2. Before installing the protective frame, first set the position on the convex edge 9 on bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com