Horizontal type continuous intensive mixing pelletizer with double functions

A dual-function, pelletizing machine technology, applied in the direction of extrusion granulation of raw materials, granulation in a rotating tank, etc., can solve the problems of continuous production of pellets, poor quality of pelletized products, low work efficiency, etc. The effect of low energy consumption, high production efficiency and improved material mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

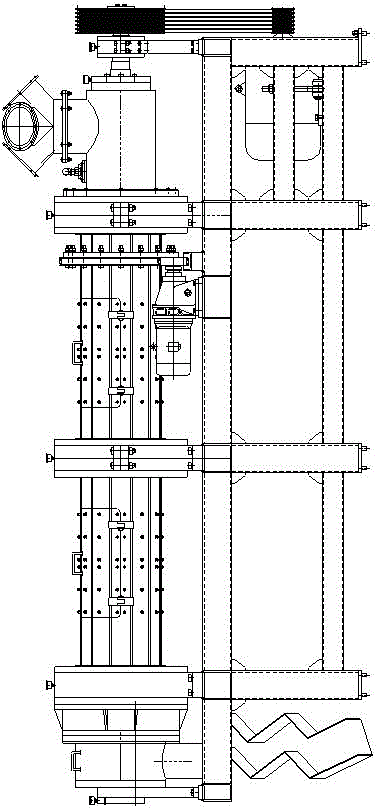

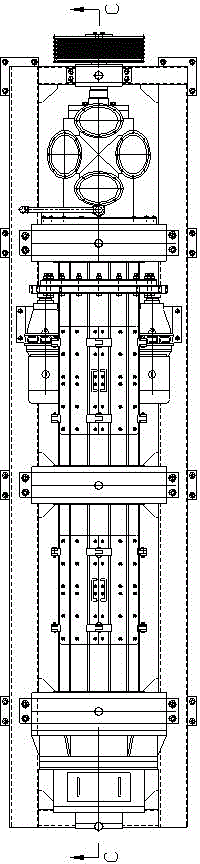

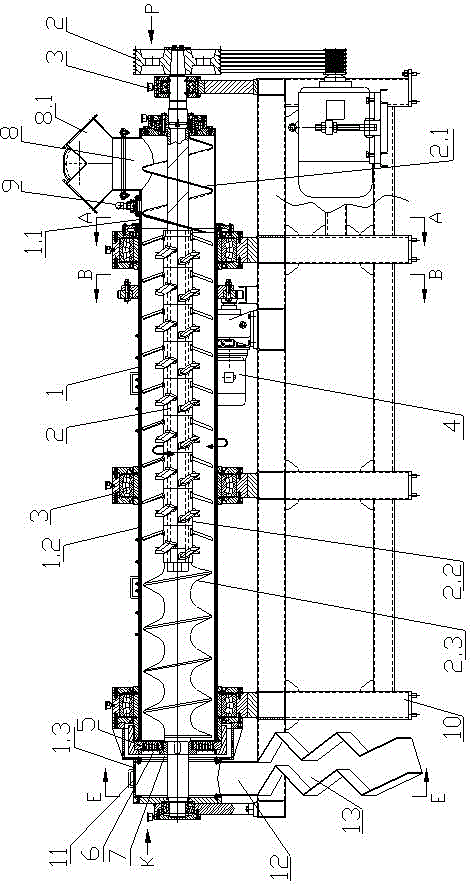

[0041] see Figure 1~Figure 12 , the present invention relates to a horizontal continuous dual-function strong mixing pelletizer, which includes a cylinder 1 and a rotating shaft 2.

[0042] Cylinder 1 includes the feeding cylinder 1.1 at the right end, the rotating cylinder 1.2 at the middle, and the discharging cylinder 1.3 at the left end. The left and right ends of the rotating cylinder 1.2 are mounted on three rotating cylinder bearing seats arranged in the left, middle and right respectively. 3, the rotating cylinder 1.2 can rotate in the rotating cylinder bearing seat 3, the outer edge of the left end of the feeding cylinder 1.1 is fixed with a rotating cylinder bearing seat 3 on the right through a mounting flange, and the discharging cylinder 1.3 The outer edge of the right end of the cylinder is fixed with a rotating cylinder bearing seat 3 on the left side by a mounting flange. The inner wall of the cylinder body 1 is provided with a wear-resistant lining.

[0043...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com