Material mixing device

A material mixing and storage tank technology, which is applied to mixers, mixers with rotating stirring devices, dissolution, etc., can solve the problems of physical injury of workers, excessive mixing drum residue, indoor environmental pollution, etc., and reduce indoor environment. Pollution, improve material mixing efficiency, improve the effect of working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

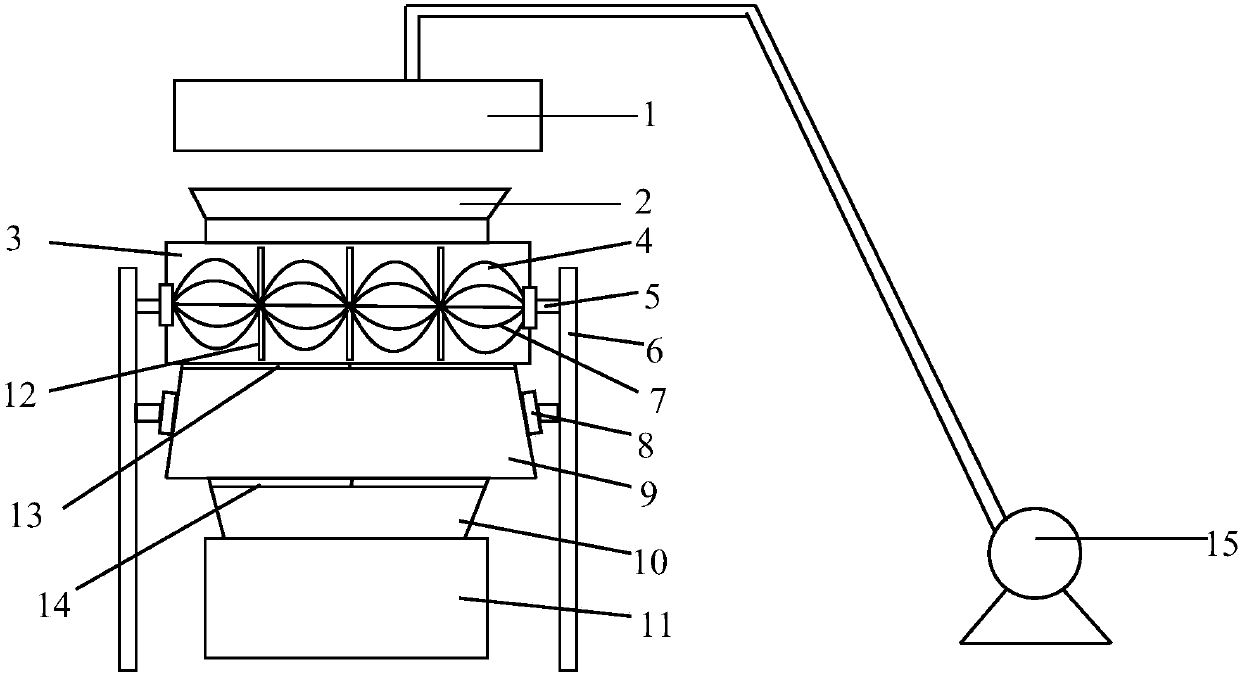

Embodiment

[0013] A material mixing device, comprising a bracket 6, a feed port 2, a mixing drum 3 and a material storage drum 9, the mixing drum 3 is connected to the upper end of the support 6 through a bearing 5, a feeding port 2 is arranged above the mixing drum 3, and the feeding port 2. A dust removal cover 1 is provided above, and the dust removal cover 1 is connected to the induced draft fan 15 through a ventilation pipe. A storage tank 9 is provided under the mixing drum 3. A discharge port 10 is provided below the storage tank 9. A second An electric rotating baffle 13, a second electric rotating baffle 14 is provided at the bottom of the material storage cylinder 9, an electromagnetic vibrator 8 is provided on both sides of the material storage cylinder 9, a rotating shaft is arranged inside the mixing drum 3, and the rotating shaft is connected to the motor through a circuit , there are four outer helical coil groups and four inner helical coil groups on the rotating shaft. C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com