Mechanical optical shutter device for laser

A laser and mechanical technology, applied in the direction of lasers, laser parts, laser parts, etc., can solve the problems that the laser cannot be turned off, the Q switch is expensive, and cannot be widely used, so as to achieve good response time and quick action Sex and reliability, cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

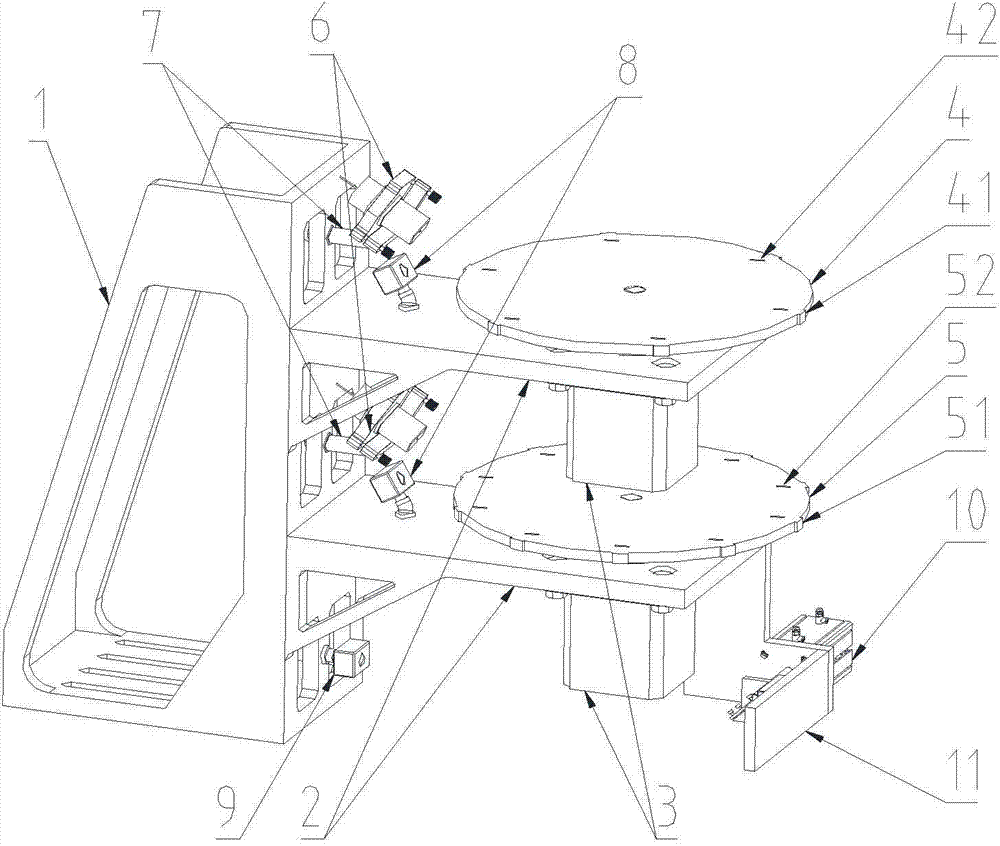

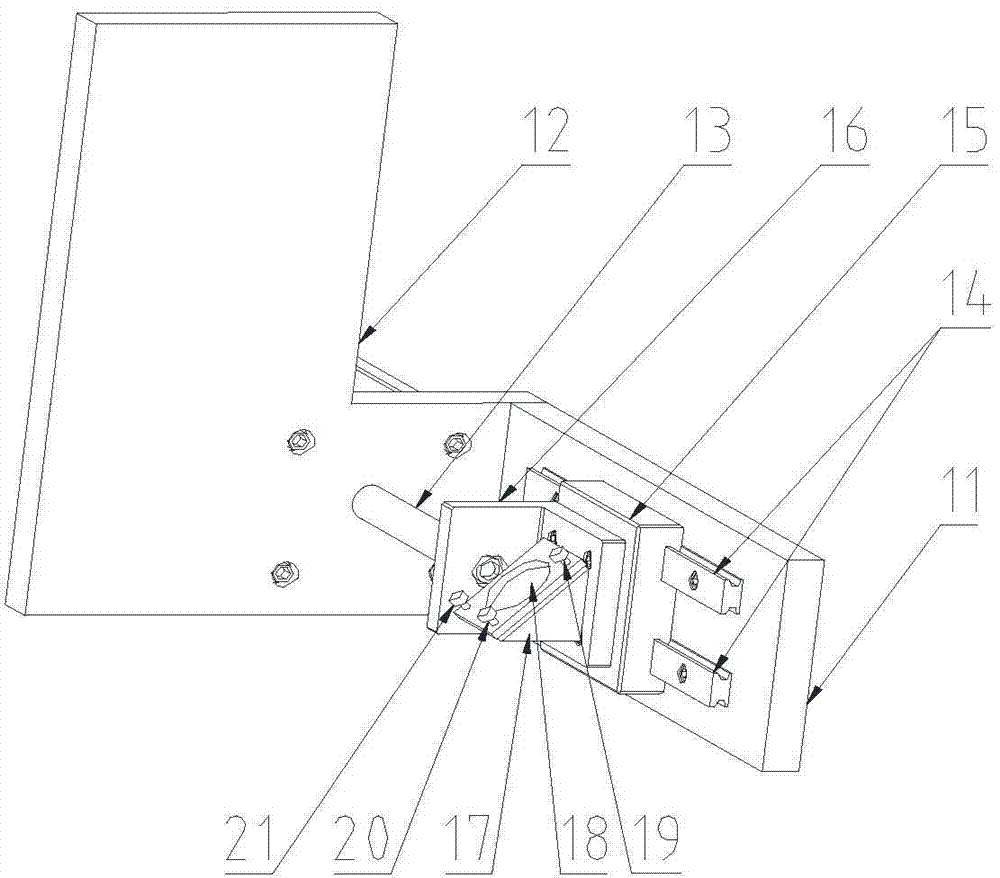

[0027] Such as Figure 1~4 As shown, the mechanical shutter device of the laser includes a pulse scanning mechanism, a pulse adjusting mechanism and a light output mechanism. Rotary disk 5, each processing has several through holes on it (there are N1 through holes 42 on the upper rotating disk 4 and N2 through holes 52 on the lower rotating disk 5), the upper rotating disk 4 and the lower rotating disk 5 pass through the rotation respectively The central hole of the disc is connected with the drive shaft of the servo motor 3, and the servo motor 3 is installed on the turntable fixing bracket 2.

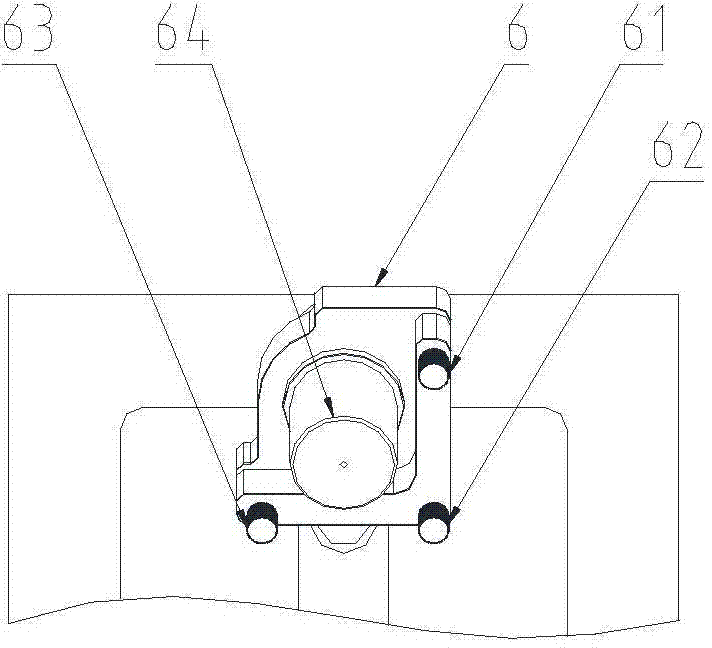

[0028] The pulse adjustment mechanism includes several mirrors 41 installed on the side of the upper rotating disk 4, several reflecting mirrors 51 installed on the side of the lower rotating disk 5, a semiconductor laser 64 and a rotating disk photoelectric detection device 8, and the semiconductor laser 64 is installed on the semiconductor laser. On the support 6 , the semiconduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com