Secondary battery composite membrane, preparation method thereof and secondary battery

A composite diaphragm and secondary battery technology, which is applied in secondary battery manufacturing, secondary batteries, battery pack components, etc., can solve the problems of inability to intercept falling off electrode materials, inability to improve battery cycle performance, etc., to prevent capacity decline, Stable structure and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

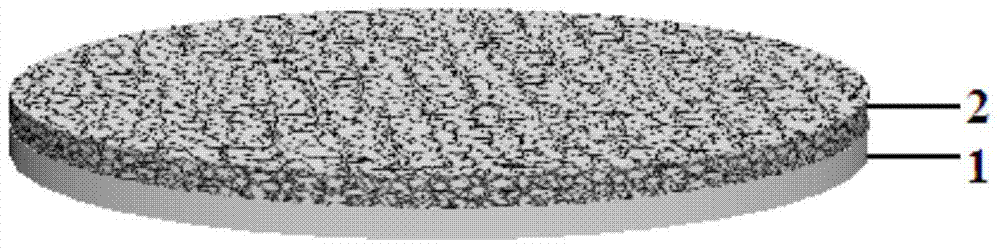

[0036] Correspondingly, the embodiment of the present invention also provides a preparation method of the secondary battery composite separator described above. For the process flow of the preparation method of the secondary battery composite diaphragm, please refer to figure 2 , see also the figure 1 , which includes the following steps:

[0037] Step S01. Prepare a dispersion or slurry containing a conductive material:

[0038] Dispersing conductive materials and surfactants into liquid solvents to prepare conductive material dispersions, or adding conductive materials and binders to solvents to prepare conductive material slurries;

[0039] Step S02. Apply the dispersion or slurry containing the conductive material to the conductive layer on the surface of the electrically insulating substrate:

[0040] The conductive material dispersion prepared in step S01 is formed on the surface of the electrical insulating substrate 1 to form a conductive layer 2 to form a first co...

Embodiment 1

[0065] A composite diaphragm for a secondary battery and a preparation method thereof. The structure of the secondary battery composite separator is as follows figure 1 shown. It comprises an electrically insulating matrix layer 1 and a conductive layer 2 combined on the surface of the electrically insulating matrix layer 1 . Wherein, the material of the electrically insulating matrix layer 1 is Celgard 2400 lithium-ion battery polymer diaphragm; the thickness of the conductive layer 2 is 20 μm, which includes carbon nanotubes as the conductive material.

[0066] The preparation method of the secondary battery composite diaphragm is as follows:

[0067] S11. Conductive material and povidone are added in dehydrated alcohol according to the ratio of mass ratio 5:1, carry out sufficient dispersion, be mixed with uniform conductive material dispersion liquid;

[0068] S12. The conductive material dispersion prepared in step S11 is filtered to flow through the electrical insulat...

Embodiment 2

[0072] A composite diaphragm for a secondary battery and a preparation method thereof. The structure of the secondary battery composite separator is as follows figure 1 shown. It comprises an electrically insulating matrix layer 1 and a conductive layer 2 combined on the surface of the electrically insulating matrix layer 1 . Wherein, the material of the electrically insulating matrix layer 1 is selected from Celgard 2400 polymer diaphragm; the thickness of the conductive layer 2 is 30 μm, which includes graphene as the conductive material and polyvinylidene fluoride as the binder, and the conductive material and the binder The mass ratio is 4:1.

[0073] The preparation method of the secondary battery composite diaphragm is as follows:

[0074] S21. Add the conductive material and the binder into the nitrogen methyl pyrrolidone according to the mass ratio of 4:1, carry out sufficient mixing treatment, and prepare a uniform conductive material slurry;

[0075] S22. Coating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com