Full-dry nonmetal self-supporting skeleton-type optical cable

A skeleton type optical cable, non-metallic technology, applied in the field of optical communication, can solve the problems of increasing construction difficulty and cost, reducing tensile strength, small volume ratio of optical fiber, etc., to facilitate construction connection and maintenance, facilitate divergence and disk retention, high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

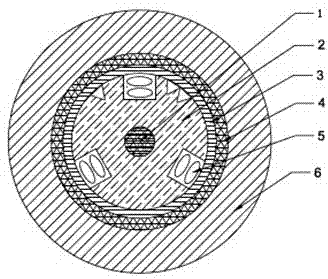

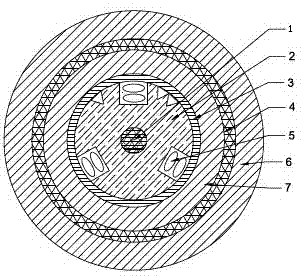

[0018] The first example is figure 1 As shown, it includes the outer sheath 6 and the skeleton 2. The skeleton is made of high-density polyethylene, which has good lateral pressure resistance and has a good protective effect on the optical communication unit. Convenience of connection; 3~12 longitudinal fiber grooves are set at intervals on the outer circumference of the frame, the transverse section of the longitudinal fiber grooves is U-shaped, the longitudinal fiber grooves are helically twisted or SZ twisted, and optical communication units are filled and installed in the longitudinal fiber grooves 5. The optical communication unit is an optical fiber or an optical fiber ribbon, and the optical fiber ribbon can be a 4-core, 6-core, 8-core or 12-core ribbon; the center of the skeleton is equipped with a non-metallic center reinforcement 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com