Titanium dioxide slurry transmittance measurement and test method

A technology of titanium dioxide and testing methods, applied in the direction of measuring devices, analytical materials, instruments, etc., can solve the problems of inconvenient technical exchange and technical improvement, large difference in measurement results, poor repeatability of measurement results, etc., and achieve easy promotion, convenient operation, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

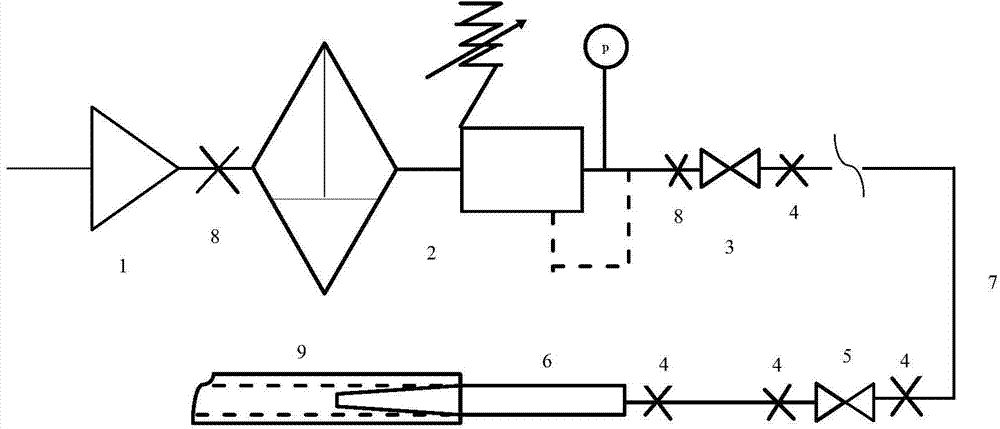

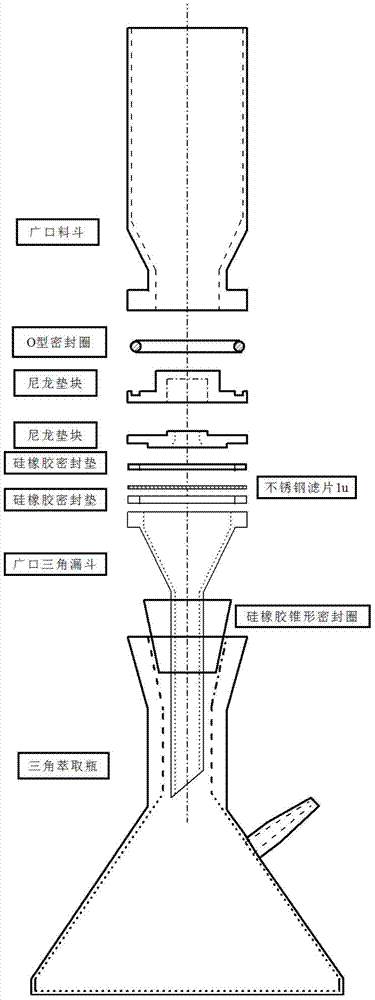

[0026] Please see attached figure 1 , a device for measuring the transmittance of titanium dioxide slurry, which includes a pressure control system; it is characterized in that the size conversion joint is connected to the factory's instrument compressed air, and the small end of the size conversion joint passes through the double thread of the size joint G1 / 4 The joint is connected with the filter pressure reducing valve group, the filter pressure reducing valve group is connected with the ball valve of the large and small joint G1 / 4 through the double threaded joint of the large and small joint G1 / 4, the plug-in threaded joint is connected with the ball valve and then connected to the plastic air pipe, and the other end is inserted The plug-in threaded joint is connected to the stop valve, the stop valve is connected to the plug-in threaded joint and connected to the L-shaped plug-in threaded joint through a plastic air pipe, and finally the L-shaped plug-in threaded joint is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com