Rotating disk microfluidic concentration measurement device and method based on photometric detection

A concentration measurement and detection device technology, which is applied in the direction of color/spectral characteristic measurement, etc., can solve the problems that the optimal optical path value is difficult to judge in advance, the concentration value of the object to be detected cannot be known in advance, and cannot be applied, so as to make up for the detection accuracy defect , easy to be portable, and reduce the effect of detection error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

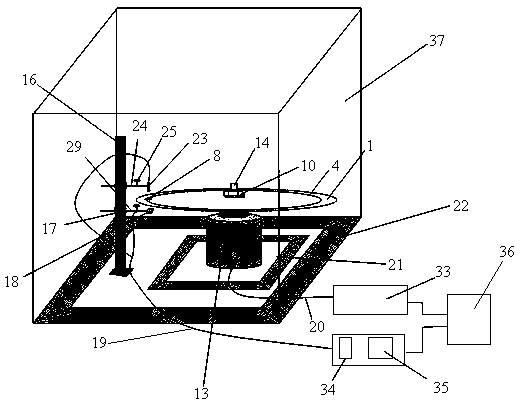

[0024] see figure 1 , is the overall structure diagram of a rotating disk microfluidic concentration measuring device based on photometric detection in the present invention. Inside a sealed darkroom 37, components such as a rotating disk microfluidic chip 1, an experimental device base 22, a photometric detection device bracket 16, and an AC servo motor 13 are arranged. Wherein, the experimental device base 22 is fixed on the bottom wall of the sealed darkroom 37, the photometric detection device support 16 is perpendicular to the experimental device base 22, and is also perpendicular to the bottom surface of the sealed darkroom 37, and the bottom of the photometric detection device support 16 is vertically welded and fixed In the center of the experimental device base 22 and the sealed dark room 37 near the left edge. The base 22 of the experimental device and the bracket 16 of the photometric detection device constitute the most basic supporting frame of the whole device....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com