Continuous pump storage unit axis measuring and adjusting method

A pumped storage unit and axis measurement technology, which is applied to measuring devices, instruments, and electric devices, etc., can solve the problems of uneven rotational speed of the large shaft and reduce the working time of cranking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, so as to understand the essence of the present invention more clearly and intuitively.

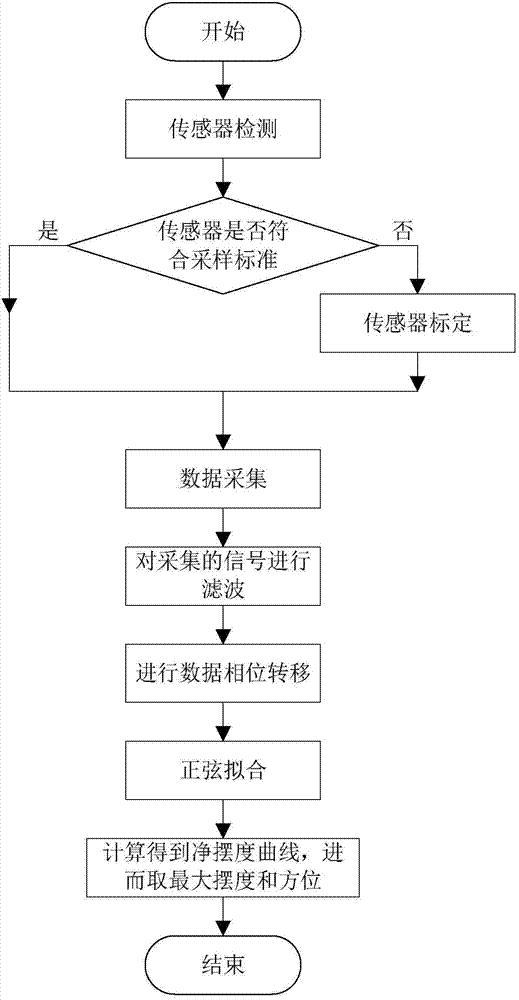

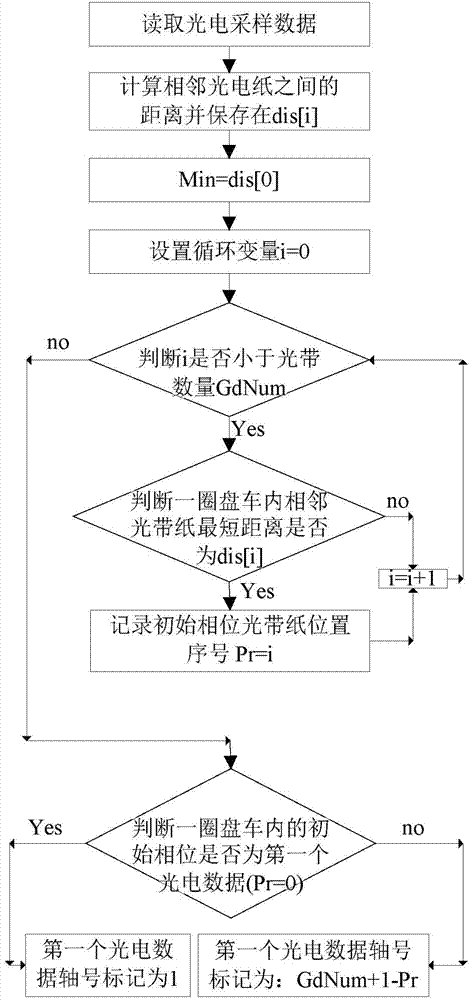

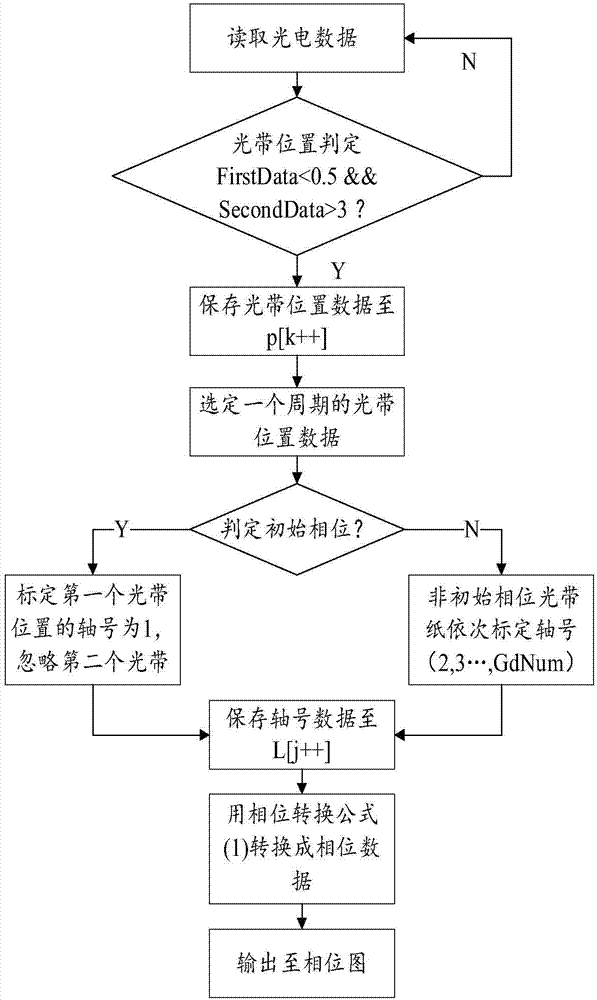

[0054] like figure 1 As shown, it is an embodiment of the method for adjusting the axis of the pumped storage unit according to the present invention, and the intelligent adjustment system for the axis of the pumped storage unit used in the method is as follows: Figure 5, including sequentially connected sensor system 1, data acquisition system 2, and data processing and analysis system 3, the data processing and analysis system includes three main modules, sequentially connected software filtering 31, phase recognition 32, and data sine fitting 33, for the present have technology.

[0055] This method comprises the following steps:

[0056] S1: Sensor calibration: calibrate the sensors of each channel before turning;

[0057] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com