Three-dimensional working table for contact pin type three-dimensional roughness measurement instrument

A technology of workbench and measuring instrument, which is applied in the direction of mechanical roughness/irregularity measurement, etc., can solve the problems of restricting the promotion of instruments and affecting the accuracy of measurement results, etc., and achieve the problems of insufficient accuracy, enhanced adaptability, and improved measurement accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

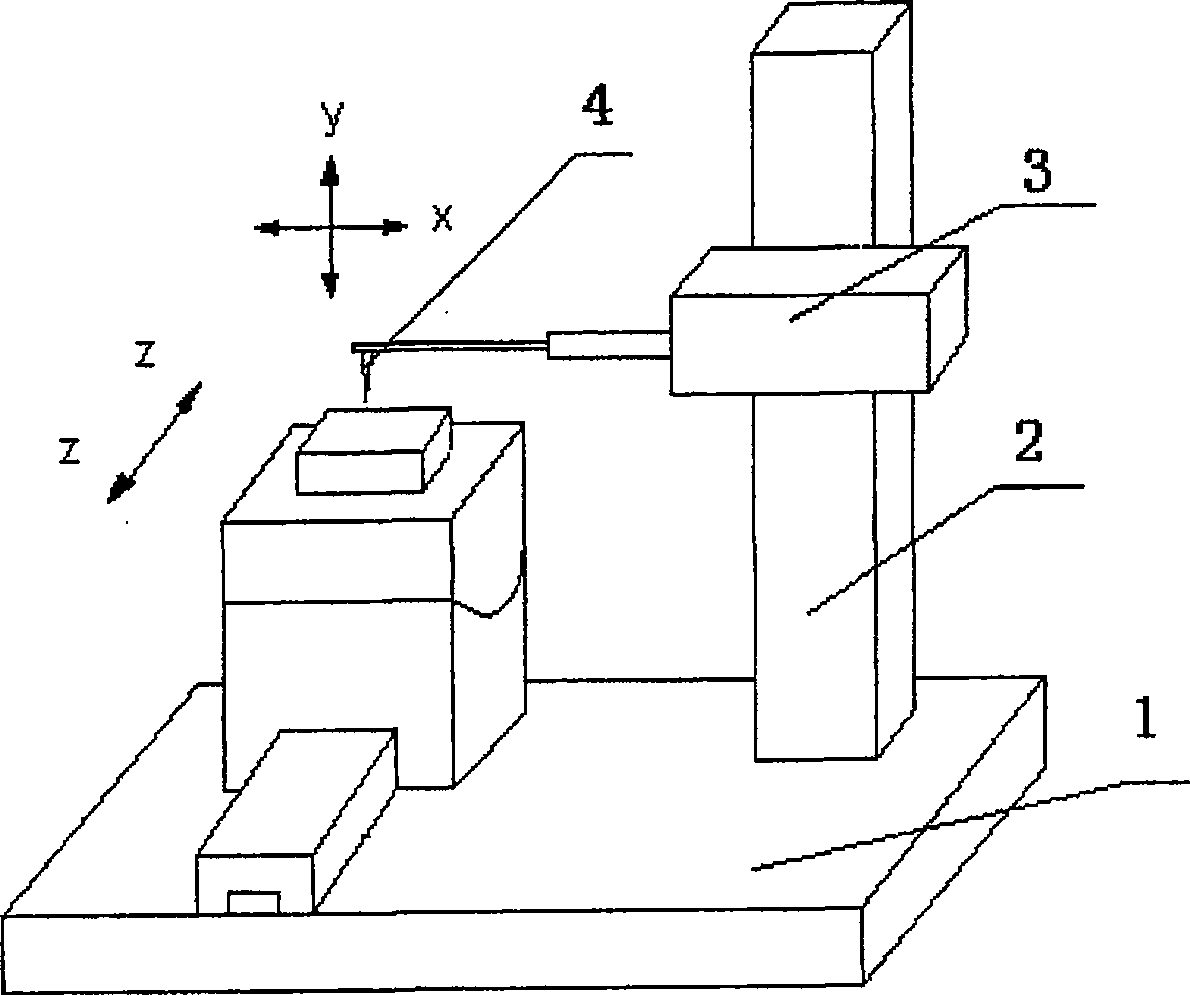

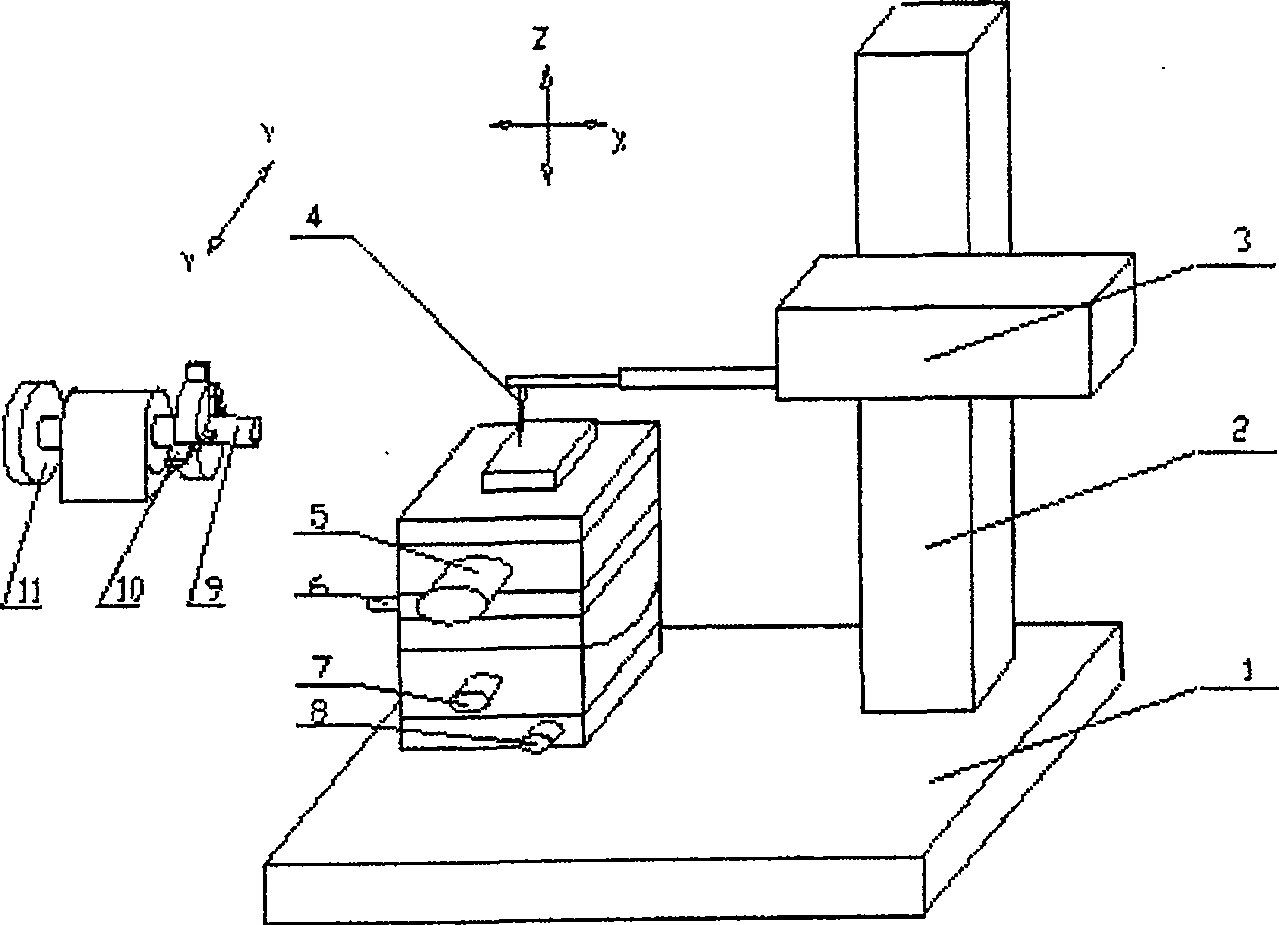

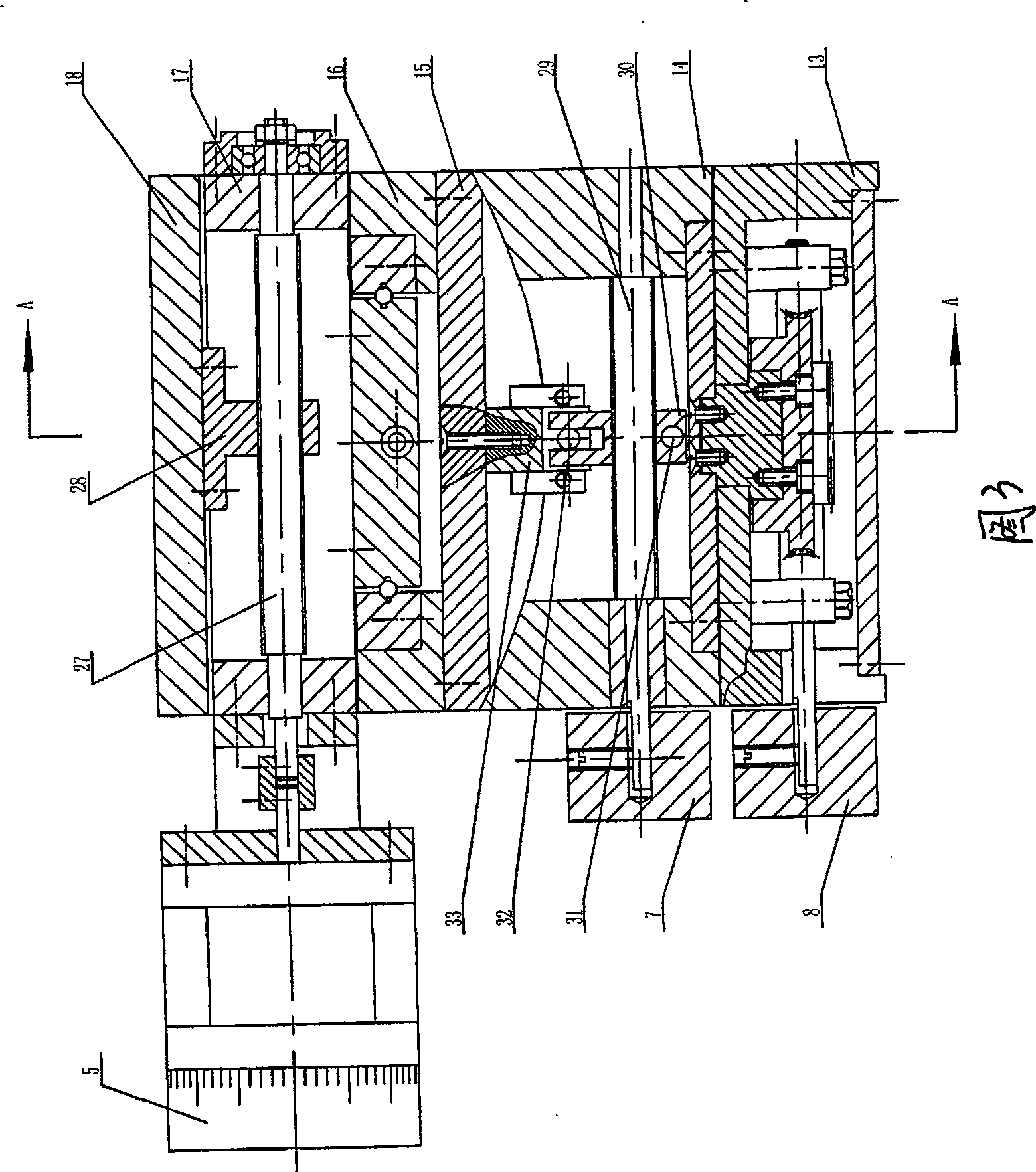

[0040] Such as figure 2 As shown in to 6, the measuring instrument is composed of a basic platform 1, a three-dimensional workbench 21, a stylus 4, a driving and sensing device 3, and a column 2. The column 2 is installed on the basic platform 1, and the driving and sensing device 3 is connected with the nut through a nut. The lead screw in the column 2 is connected to the column 2, the contact pin 4 is connected to the driving and sensing device 3, and the three-dimensional workbench is installed on the basic platform 1. The first floor 13, the second floor 14, the third floor 15, the fourth floor 16, the fifth floor 17 and the sixth floor 18, the sixth floor 18 Located on the top of the three-dimensional workbench, the first-layer workbench 13 is located at the bottom of the three-dimensional workbench; the No. The T-shaped bolts are fixed on the T-shaped groove of the foundation platform 1, and the worm gear and worm connection mechanism is installed between the workbench...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com