An open biomass gas combustion engine

A biomass and gas-fired engine technology, applied in the control of combustion, combustion method, combustion equipment, etc., can solve the problems of high airtightness, complex structure, high cost, and achieve the effect of convenient operation, easy movement and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

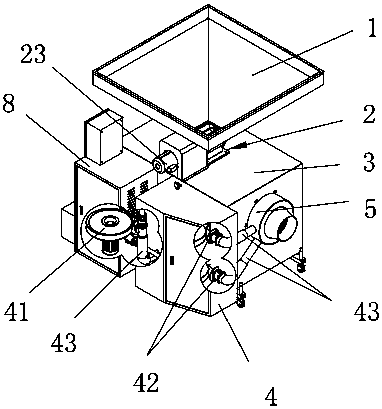

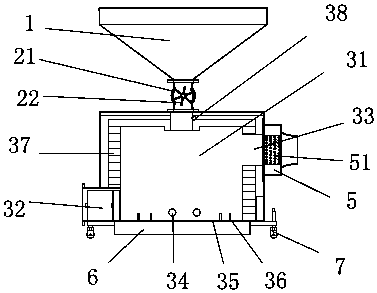

[0021] Such as figure 1 , figure 2 An open biomass gas combustion engine shown includes a furnace body 3, a furnace body 31 is provided inside the furnace body 3, a refractory insulating material layer 37 is poured on the furnace wall of the furnace 31, and an automatic ignition device 34 is provided at the bottom of the furnace 31 The upper part of the furnace 31 is provided with an in-chamber temperature sensor 38; the lower part of the side wall of the furnace body 3 is provided with a cleaning port 32 in communication with the furnace 31, and the upper part of the side wall of the furnace body 3 is provided with a fire port 33 in communication with the furnace 31. A silo 1 is provided above the furnace body 3, and the silo 1 is an open inverted cone structure; a feeding device 2 is provided between the silo 1 and the furnace body 3, and the feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com