A structure for reducing internal force of tunnel lining structure and its construction method

A technology of structural internal force and construction method, which is applied in the construction of the structure, the structure that reduces the internal force of the tunnel lining structure, and the field of tunnel support design, can solve the problems of large internal force of the support structure, large surface settlement and deformation, etc., and achieve the support strength. The effect of weakening, reducing surface subsidence deformation, and reducing the amount of surface subsidence deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

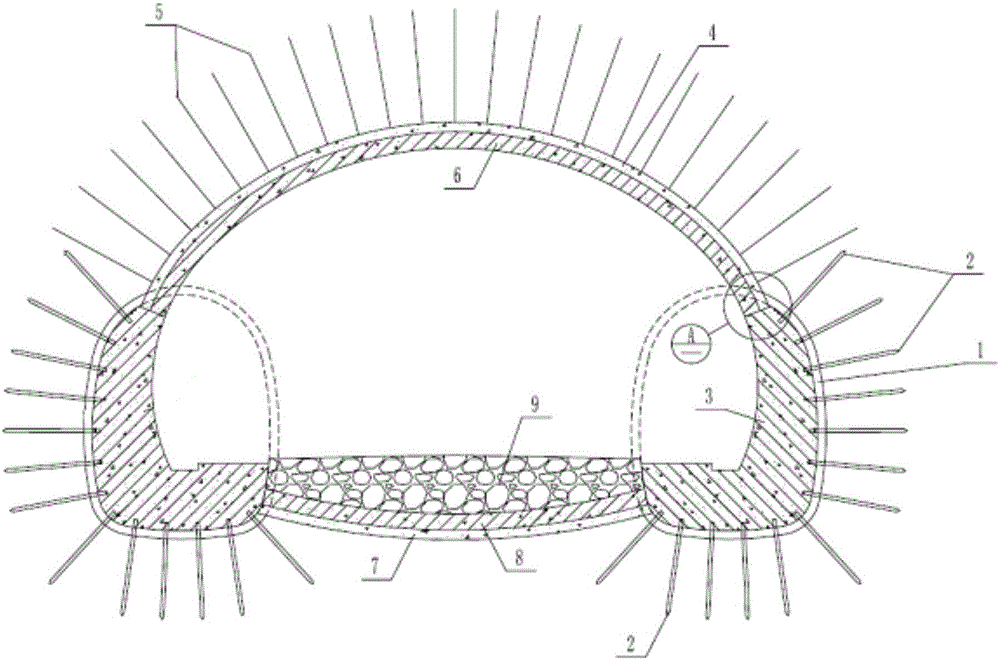

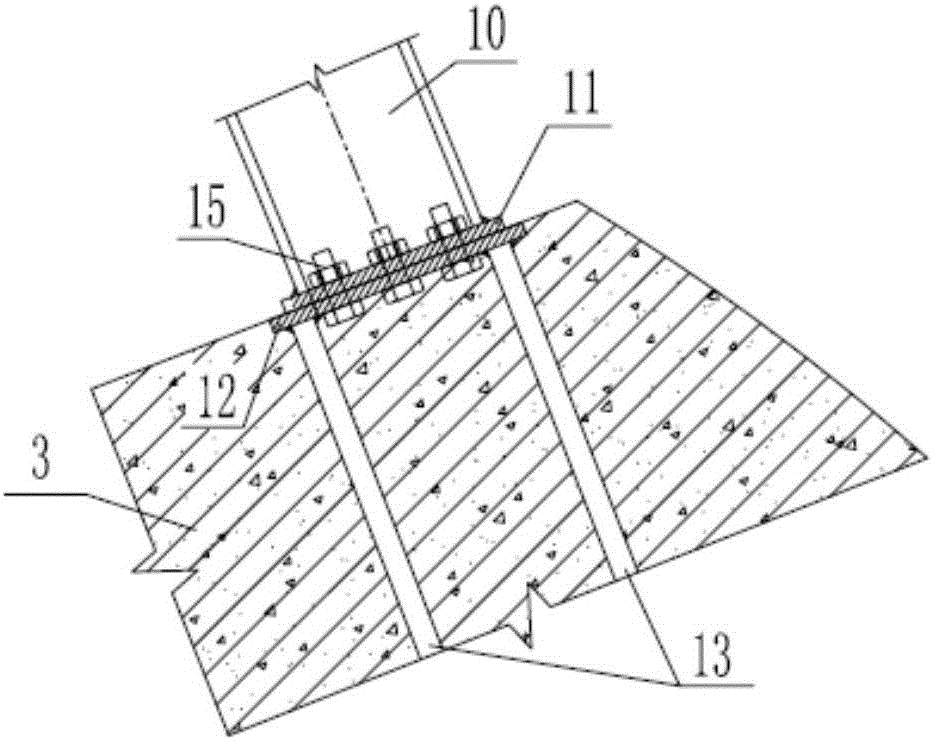

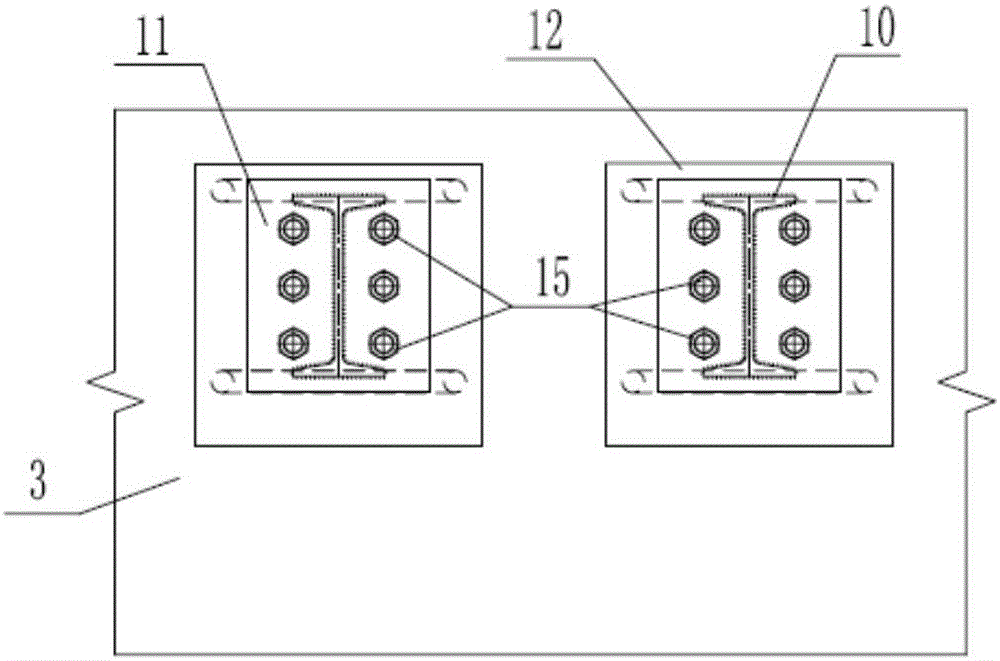

[0039] The structure of the structure for reducing the internal force of the tunnel lining structure provided by this embodiment is as follows figure 1 As shown, the structure at least includes the initial support of the pilot pit 1, the initial support of the arch 4, the initial support of the invert 7, the second arch lining 6, the second invert lining 8 and the invert backfill 9. The initial arch support includes at least an arch frame 10, and anchor rods 5 are evenly distributed on the arch initial support. The initial support of the pilot pit 1 includes the initial support of the left pilot pit and the initial support of the right pilot pit. Small conduits 2 are evenly provided on the side walls of the left pilot pit initial support and the right pilot pit initial support in contact with the surrounding rock. The left side wall lining is provided on the inner side of the side wall where the initial support of the left pilot pit is in contact with the surrounding rock, and ...

Embodiment 2

[0043] The structure of the structure for reducing the internal force of the tunnel lining structure provided by this embodiment is as follows figure 1 As shown, the structure includes at least the initial support 1 of the pilot pit, the initial support 4 of the arch, the initial support 7 of the invert, the second lining of the arch 6, the second lining of the invert 8 and the backfill 9 of the invert. The initial arch support includes at least an arch frame 10, and anchor rods 5 are evenly distributed on the arch initial support. The initial support of the pilot pit 1 includes the initial support of the left pilot pit and the initial support of the right pilot pit. Small conduits 2 are evenly provided on the side walls of the left pilot pit initial support and the right pilot pit initial support in contact with the surrounding rock. The left side wall lining is provided on the inner side of the side wall where the initial support of the left pilot pit is in contact with the s...

Embodiment 3

[0062] 1) Excavate the pilot pits on both sides of the tunnel, and implement the initial support of the left pilot pit and the initial support of the right pilot pit. Small pipes are uniformly applied on the side walls where the initial support of the left pilot pit and the initial support of the right pilot pit are in contact with the surrounding rock, and the surrounding rock is reinforced by grouting through the small pipes on both sides. The small conduit should be a seamless steel tube with a diameter of 30-50mm and a length of 25-400mm. The grouting material can be cement single-liquid slurry, cement-water glass double-liquid slurry, etc. according to the geological conditions. The selection, proportion and grouting pressure of grouting materials should be determined by experiments.

[0063] 2) Construct the left thick side wall lining on the inner side of the side wall where the initial support of the left pilot pit is in contact with the surrounding rock, and construct th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com