Construction method for carrying out sea reclamation with sand in shallow sea area through cutter suction dredger

A cutter-suction dredger, land reclamation technology, applied in land reclamation, mechanically driven excavators/dredgers, climate change adaptation, etc., can solve problems such as damage to marine ecological environment, reduction of coastline resources, etc., to achieve Reduce construction costs, improve construction efficiency, and protect the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

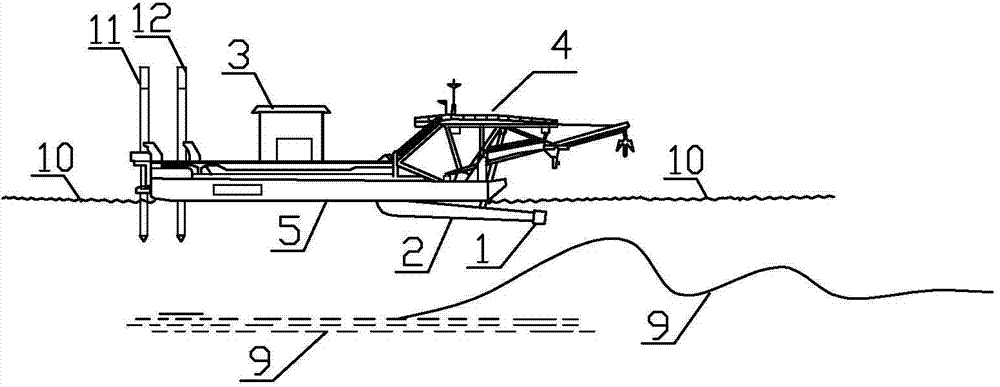

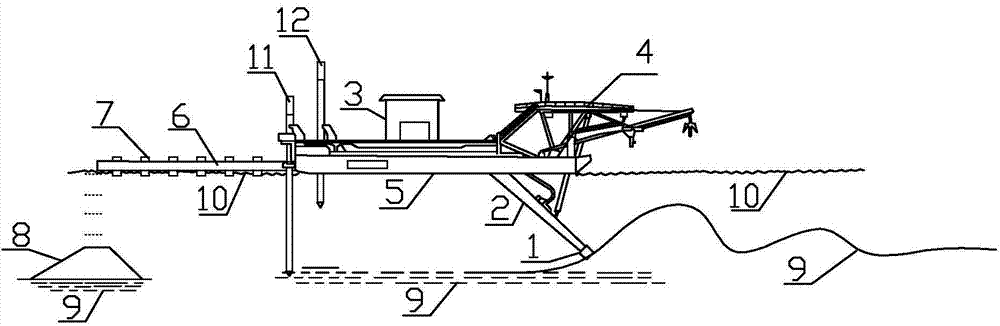

[0080] A construction method for land reclamation by sand blowing in shallow sea areas using a cutter suction dredger, the cutter suction dredger comprising a cutter suction head 1, a suction pipe 2, a power system 3, a bow 4 and a hull 5;

[0081] The twisted suction head 1 is used to suck the seabed sand, and the suction pipe 2 is used to transport the sucked seabed sand to the sand blowing conduit 6 through the power system 3;

[0082] The power system 3 mud pump; the mud pump of the power system provides power for the cutter suction head 1 to absorb the seabed sand and the suction pipe 2 to transport the seabed sand. At the same time, the power system 3 also provides power for the movement of the cutter suction dredger hull;

[0083] The bow 4 is the bow mechanical assembly, which is used for fixing the suction pipe 2 and the twisting suction head 1, and positioning the hull;

[0084] The hull 5 provides a working surface for sand blowing reclamation;

[0085] The present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com