Fabric with flame-retardant function and anti-bacterial function and manufacturing method of fabric

A fabric and functional technology, applied in the field of fabrics with flame retardant and antibacterial functions and its preparation, can solve the problems of difficulty in obtaining flame retardant effect, only flame retardant effect, limited flame retardant effect, etc., and achieve significant flame retardant effect, The effect of excellent antibacterial performance, good durability and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

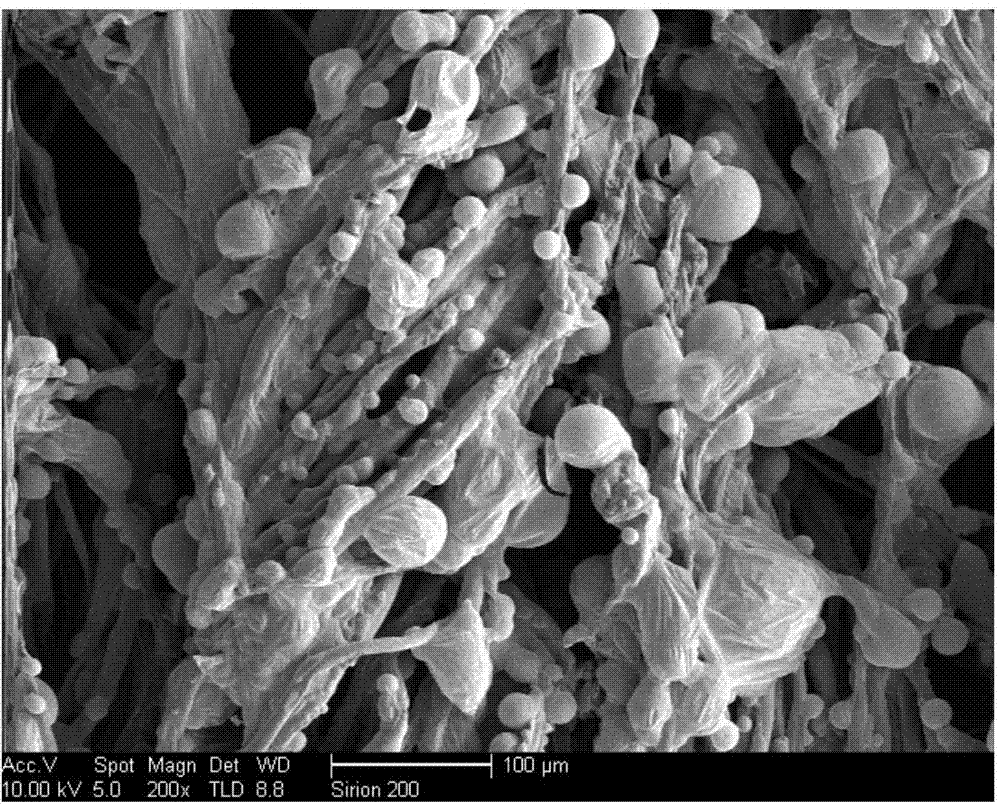

Image

Examples

Embodiment 1

[0033] The concrete steps of preparation are:

[0034] Step 1, adding polyhexamethylene guanidine salt and polyphosphate salt into deionized water respectively and stirring for 1 hour to obtain 0.05g / 100g polyhexamethylene guanidine salt aqueous solution and 5g / 100g polyphosphate aqueous solution; wherein, poly The hexamethylene guanidine salt is polyhexamethylene guanidine phosphate, and the polyphosphate is ammonium polyphosphate.

[0035] Step 2, first immerse the fabric in the polyhexamethyleneguanidine saline solution for 10 seconds, then take it out, rinse it with distilled water for 120 seconds, and then place it at 50°C for 60 minutes to obtain a fabric stained with polyhexamethyleneguanidine salt; , the fabric is cotton fabric. Then soak the fabric stained with polyhexamethylene guanidine salt in the polyphosphate aqueous solution for 10 seconds, take it out, rinse it with distilled water for 120 seconds, and then place it at 50°C for 60 minutes to obtain polyhexamet...

Embodiment 2

[0038] The concrete steps of preparation are:

[0039] Step 1, adding polyhexamethylene guanidine salt and polyphosphate salt into deionized water respectively and stirring for 1.5h to obtain 1.25g / 100g polyhexamethylene guanidine salt aqueous solution and 3.75g / 100g polyphosphate aqueous solution; wherein , polyhexamethylene guanidine salt is polyhexamethylene guanidine phosphate, and polyphosphate is ammonium polyphosphate.

[0040] Step 2, first immerse the fabric in the polyhexamethyleneguanidine saline solution for 35 seconds, then take it out, rinse it with distilled water for 95 seconds, and then place it at 58°C for 50 minutes to obtain a fabric stained with polyhexamethyleneguanidine salt; , the fabric is cotton fabric. Then soak the fabric stained with polyhexamethylene guanidine salt in the polyphosphate aqueous solution for 35s, take it out, rinse it with distilled water for 95s, and then bake it at 58°C for 50min to obtain polyhexamethylene Guanidine-salted and ...

Embodiment 3

[0043] The concrete steps of preparation are:

[0044] Step 1, adding polyhexamethylene guanidine salt and polyphosphate salt into deionized water respectively and stirring for 2h to obtain 2.5g / 100g polyhexamethylene guanidine salt aqueous solution and 2.5g / 100g polyphosphate aqueous solution; wherein, The polyhexamethylene guanidine salt is polyhexamethylene guanidine phosphate, and the polyphosphate is ammonium polyphosphate.

[0045]Step 2, first immerse the fabric in the polyhexamethyleneguanidine saline solution for 65 seconds, then take it out, rinse it with distilled water for 70 seconds, and then dry it at 65°C for 40 minutes to obtain a fabric stained with polyhexamethyleneguanidine salt; , the fabric is cotton fabric. Then soak the fabric stained with polyhexamethylene guanidine salt in the polyphosphate aqueous solution for 65 seconds, take it out, rinse it with distilled water for 70 seconds, and then bake it at 65°C for 40 minutes to obtain polyhexamethylene gua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com