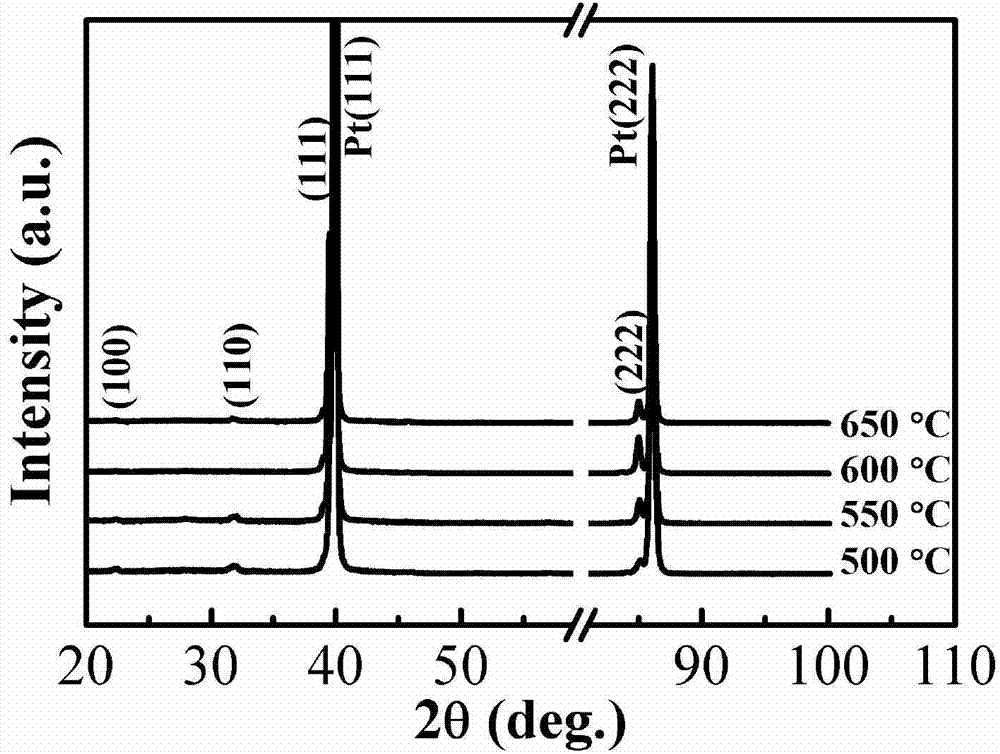

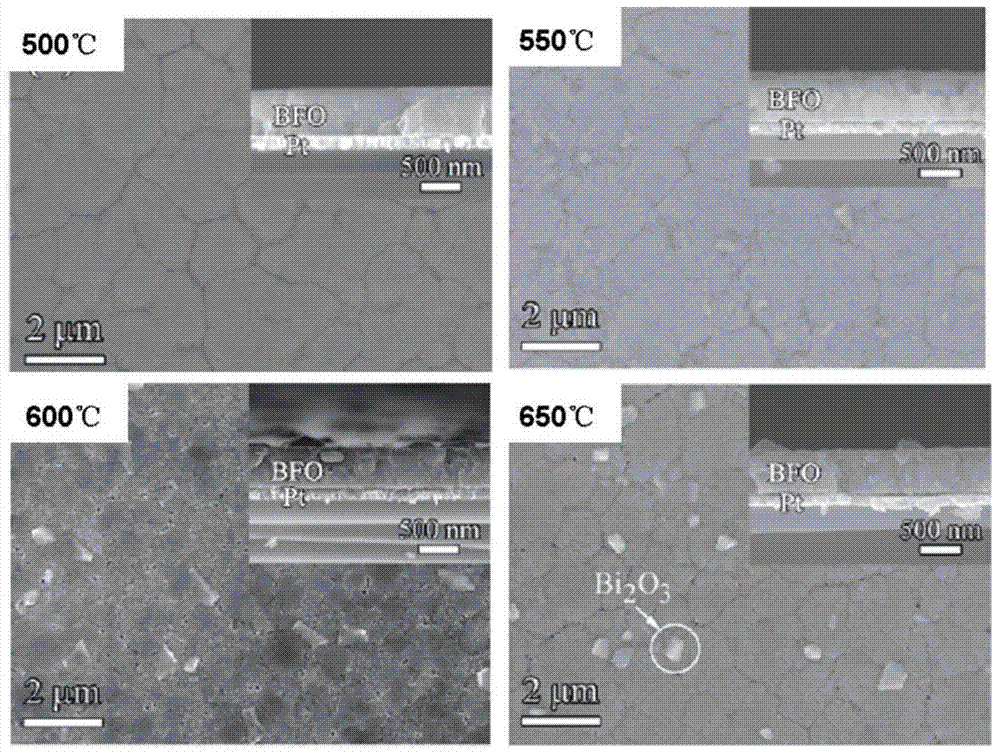

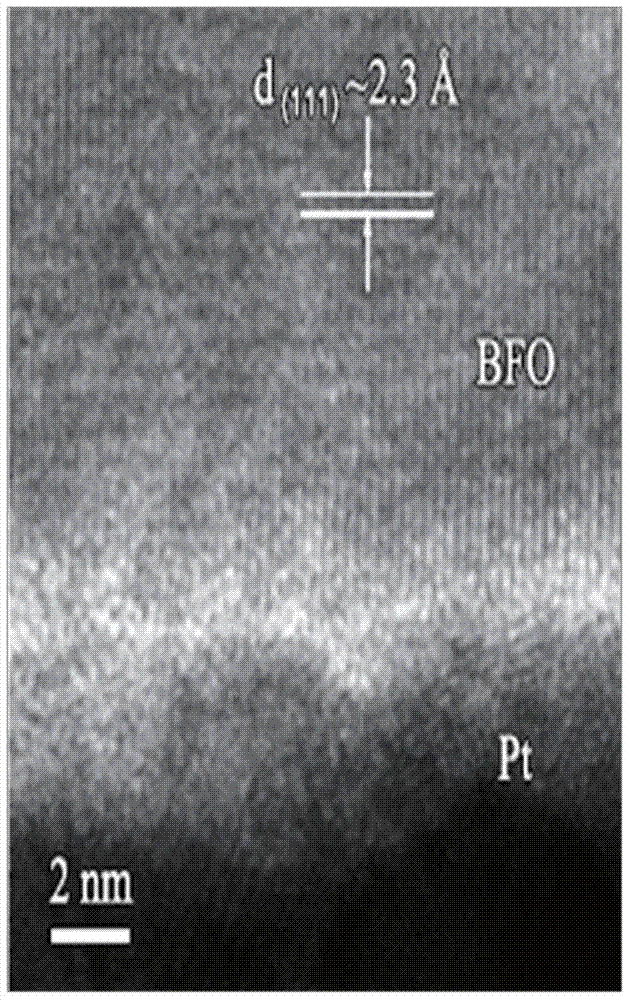

Method for preparing (111) oriented bismuth ferrite films by use of sol gel and chemical solution methods

A chemical solution method, sol-gel technology, applied in solid-state chemical plating, metal material coating process, coating and other directions, to achieve the effect of low room temperature leakage current density, less equipment, and large room electric polarization strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for preparing (111) oriented bismuth ferrite film by sol-gel and chemical solution method, comprising the following steps:

[0035] S1. Preparation of precursor solution: weigh bismuth acetate and ferrous acetate in a molar ratio of 1.02:1, add them to propionic acid, and stir to dissolve at 60°C to obtain a precursor solution, wherein the molar volume of ferrous acetate and propionic acid is The ratio (mol / L) is 0.05:1;

[0036] S2. Preparation of bismuth ferrite precursor colloid: add ethanolamine to the precursor solution obtained in S1, and stir at room temperature for 4 hours to obtain bismuth ferrite precursor colloid, wherein the volume ratio of ethanolamine and propionic acid is 1:30;

[0037] S3. Preparation of bismuth ferrite precursor thin film: The bismuth ferrite precursor colloid obtained in S2 is coated on Pt(111) / Ti / SiO 2 On the / Si substrate, the substrate was spin-coated at 3000r / min for 10s, then placed in the air, heated to 300°C, and kept ...

Embodiment 2

[0040] A method for preparing (111) oriented bismuth ferrite film by sol-gel and chemical solution method, comprising the following steps:

[0041] S1. Preparation of precursor solution: weigh bismuth acetate and ferrous acetate in a molar ratio of 1.06:1, add them to propionic acid, and stir to dissolve at 80°C to obtain a precursor solution, wherein the molar volume of ferrous acetate and propionic acid is The ratio (mol / L) is 0.3:1;

[0042] S2, preparation of bismuth ferrite precursor colloid: add ethanolamine to the precursor solution obtained in S1, and stir at room temperature for 8 hours to obtain bismuth ferrite precursor colloid, wherein the volume ratio of ethanolamine and propionic acid is 1:150;

[0043] S3. Preparation of bismuth ferrite precursor thin film: The bismuth ferrite precursor colloid obtained in S2 is coated on Pt(111) / Ti / SiO 2 On the / Si substrate, the substrate was spin-coated at 6000r / min for 60s, then placed in the air, heated to 355°C, and kept ...

Embodiment 3

[0046] A method for preparing (111) oriented bismuth ferrite film by sol-gel and chemical solution method, comprising the following steps:

[0047] S1. Preparation of precursor solution: weigh bismuth acetate and ferrous acetate in a molar ratio of 1.025:1, add them to propionic acid, and stir to dissolve at 65°C to obtain a precursor solution, wherein the molar volume of ferrous acetate and propionic acid is The ratio (mol / L) is 0.1:1;

[0048] S2, prepare bismuth ferrite precursor colloid: add ethanolamine to the precursor solution obtained in S1, and stir at room temperature for 5 hours to obtain bismuth ferrite precursor colloid, wherein the volume ratio of ethanolamine and propionic acid is 1:40;

[0049] S3. Preparation of bismuth ferrite precursor thin film: The bismuth ferrite precursor colloid obtained in S2 is coated on Pt(111) / Ti / SiO 2 On the / Si substrate, the substrate was spin-coated at 3500r / min for 20s, then placed in the air, heated to 330°C, and kept for 8mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com