Neutral water base cleaning agent combination for circuit board

A neutral water, circuit board technology, applied in detergent compositions, soap detergent compositions, surface-active non-soap compounds and detergent compositions, etc., can solve the problems such as the complete removal of surfactant residues that cannot guarantee the PCB. , to achieve the effect of good removal ability and high operating safety factor

Inactive Publication Date: 2015-08-19

SHENZHEN MAKER TECH CO LTD

View PDF5 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

During the use of neutral water-based cleaning agents, the surfactant will be adsorbed on the metal surface. Even if the clean water is used for rinsing in the later stage, there is no guarantee that the surfactant residue on the PCB can be completely removed.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-7 and comparative example 1-2

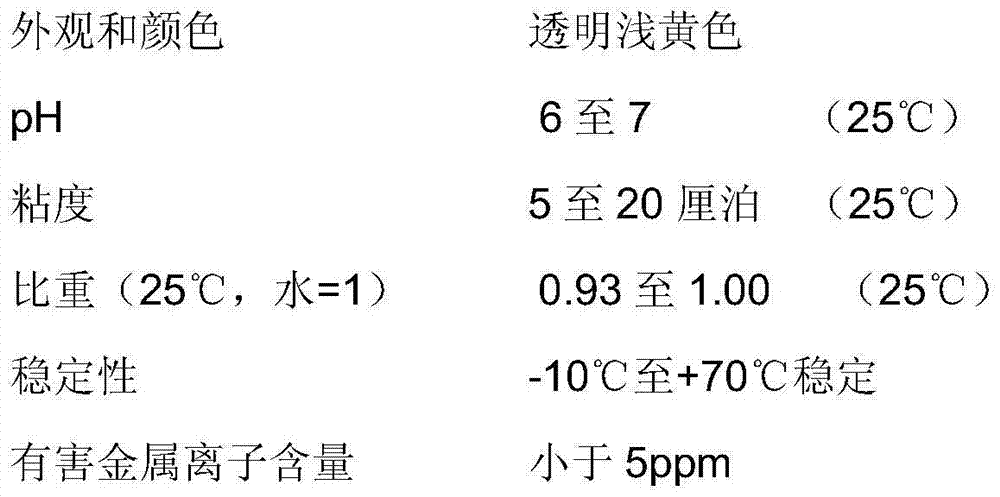

[0062] According to the proportions shown in Table 1, each component was added into deionized water to dissolve them all to obtain a uniform and transparent light-colored solution, which was a neutral water-based cleaning agent composition for circuit boards.

[0063] Table 1 Components and proportioning (percentage by weight) of Examples 1-7 and Comparative Examples 1-2

[0064]

[0065]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a neutral water base cleaning agent combination for a circuit board. The neutral water base cleaning agent combination comprises the following components in percentage by weight: 0.02 to 2% of C8-18 linear chain alkyl sulfhydryl, 0.02 to 2% of a specific sulfhydryl compound, 1 to 15% of an alcohol ether solvent, 0.02 to 5% of a nonionic surface active agent, water-soluble organic amine pH regulator and the balance of deionized water, wherein the specific sulfhydryl compound is a thiol-connected, benzene ring-free and nitrogenous five-membered heterocycle compound, and the adding amount of the water-soluble organic amine pH regulator is according to the ratio of 1:1 of an amine value to a thiol value in components. The neutral water base cleaning agent combination has a good capacity of removing flux residues after the circuit board is welded, can form composite hydrophobic organic membranes on most metal surfaces, and metals at PCB weld points and in electronic components are effectively protected and are prevented from being subjected to moisture absorption, corrosion and color change.

Description

technical field [0001] The invention belongs to the technical field of cleaning agents for the electronics industry, and in particular relates to a neutral water-based cleaning agent composition for circuit boards. Background technique [0002] Printed circuit board (hereinafter referred to as PCB) is an indispensable core component of electronic products. With the development trend of electronic product integration, high density, and high reliability, the design of the PCB used will be more compact, thin, short, multi-functional, and intelligent, and the quality requirements of the PCB are also getting higher and higher. During the PCB assembly and welding process, flux or a paste mixture of flux and tin powder (trade name: solder paste) is usually used as a soldering auxiliary material. The flux plays the role of removing the oxide film on the metal surface and reducing the surface tension of the molten solder to ensure the effectiveness of the soldering and the reliabili...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C11D10/02

Inventor 吴树文符瑄杜学晓

Owner SHENZHEN MAKER TECH CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com