A kind of method extracting active acid from Zijinniu root

A technology of violet root and active acid, applied in organic chemistry and other directions, to achieve the effect of broad industrial application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

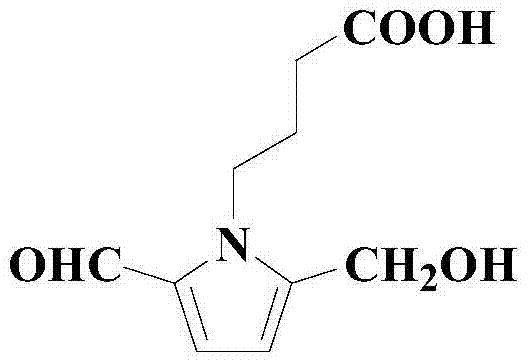

Image

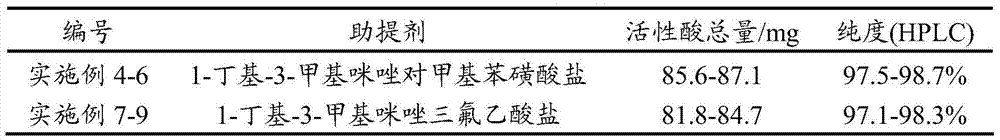

Examples

preparation example

[0047] Preparation example: Preparation of acidic silica gel

[0048] I. Bake 200-300 mesh neutral silica gel in a muffle furnace at 500°C for 4 hours. After baking, cool to 260°C and keep it for 45 minutes, and finally cool to room temperature to obtain activated silica gel;

[0049] II. Add dropwise an aqueous sulfuric acid solution with a concentration of 25% by mass to the activated silica gel. The mass ratio of the activated silica gel to the sulfuric acid contained in the aqueous sulfuric acid solution is 1:0.04, then fully shake it uniformly, and vacuum dry completely to obtain Acidic silica gel.

[0050] Unless otherwise specified, the acidic silica gel used in the following examples is the acidic silica gel obtained in this preparation example.

Embodiment 1

[0052] S1: Preparation of Purple Golden Beef Root Powder

[0053] Take dried purple golden bull root with mass water content less than 2%, and use NaHCO with a mass percentage concentration of 1% 3 Soak in the aqueous solution for 20 hours, then wash it with deionized water for 2-3 times, and after it is completely dried, pulverize and pass through a 100-mesh sieve to obtain purple golden bull root powder (ie raw material);

[0054] S2: Preparation of multi-component composite extract

[0055] Mix acetone, petroleum ether and cis-3-hexenyl 2-methylbutyrate in a mass ratio of 2:1.5:1 to obtain a mixed solution; then add 5% of the weight of the mixed solution as an auxiliary 1-butanol 3-methylimidazole dicyandiamide salt, stirred and mixed for 5 minutes at room temperature, which is a multi-component composite extract;

[0056] S3: Preparation of crude product

[0057] Add the purple golden bull root powder of step S1 to the multi-component composite extract of step S2 (the mass ratio of...

Embodiment 2

[0066] S1: Preparation of Purple Golden Beef Root Powder

[0067] Take dried purple golden bull root with mass water content less than 2%, and use 2% NaHCO 3 Soak in the aqueous solution for 25 hours, then wash with deionized water for 2-3 times, and after completely drying, crush and pass through a 100-mesh sieve to obtain purple golden bull root powder (ie raw material);

[0068] S2: Preparation of multi-component composite extract

[0069] Mix acetone, petroleum ether and cis-3-hexenyl 2-methylbutyrate in a mass ratio of 2.5:2:1 to obtain a mixed solution; then add 10% of the weight of the mixed solution as an auxiliary 1-butanol 3-methylimidazole dicyanamide salt, stirred and mixed for 8 minutes at room temperature, that is, a multi-component composite extract;

[0070] S3: Preparation of crude product

[0071] Add the purple golden bull root powder of step S1 to the multi-component composite extract of step S2 (the mass ratio of the raw material to the multi-component composite ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com