Low-formaldehyde-content high-density fiberboard

A high-density fiberboard and low-formaldehyde technology, applied in the field of fiberboard, can solve the problems of secondary pollution, high cost, and low bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

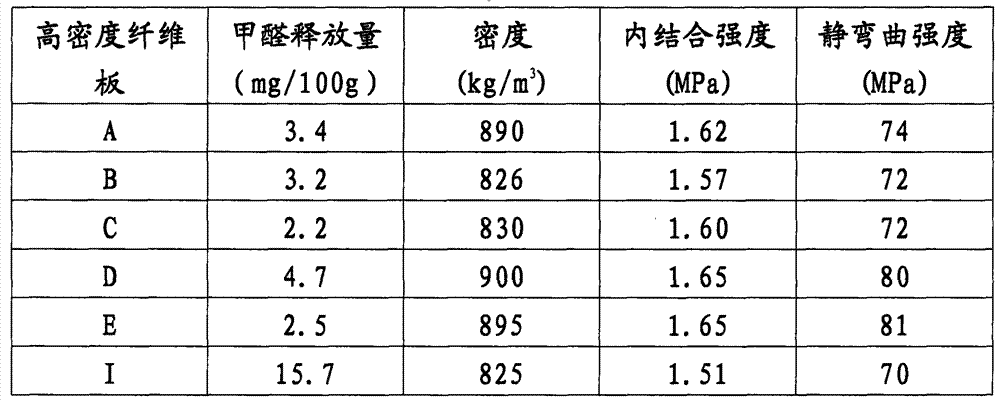

Examples

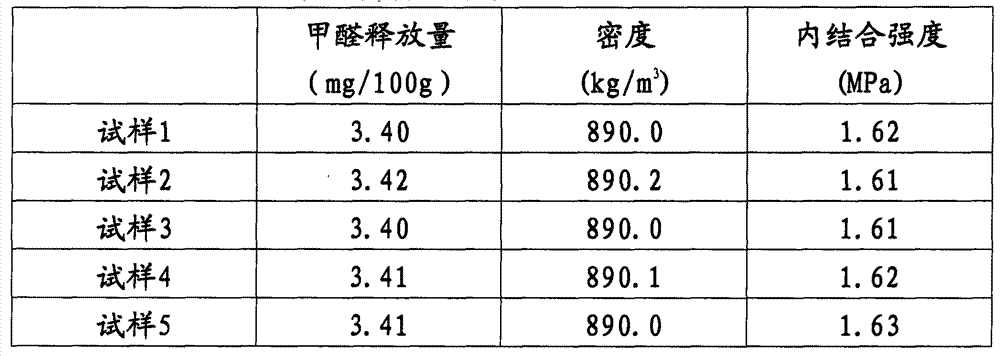

Embodiment 1

[0060] 125 parts by weight of fiber slurry, 10 parts by weight of urea-formaldehyde resin, and 6.5 parts by weight of propyl benzoate are uniformly mixed in a stirring tank, and the mixture is dried at 50-70°C until the water content is 15 wt%, to obtain a mixture. The mixture was pre-pressed at 6-7MPa for 30s to form a blank, and the blank was isostatically pressed at 8MPa and 70°C for 1min to form a slab. The slab is hot-pressed, and the hot-pressing conditions are: temperature 150-160°C; rise to 19-21MPa within 20-30s, hold pressure for 50-100s; decompress to 6-8.5MPa within 10-15s, hold Press for 65-135s; then rise to 10-14MPa within 10-15s, hold the pressure for 50-75s; finally depressurize uniformly to 0MPa within 60-120s. The hot-pressed sheet was cooled to room temperature, tempered, and sanded to obtain a high-density fiberboard A with a thickness of 30 mm.

[0061] It has been determined that the composition of the high-density fiberboard A is 85wt% fiber, 10wt% ure...

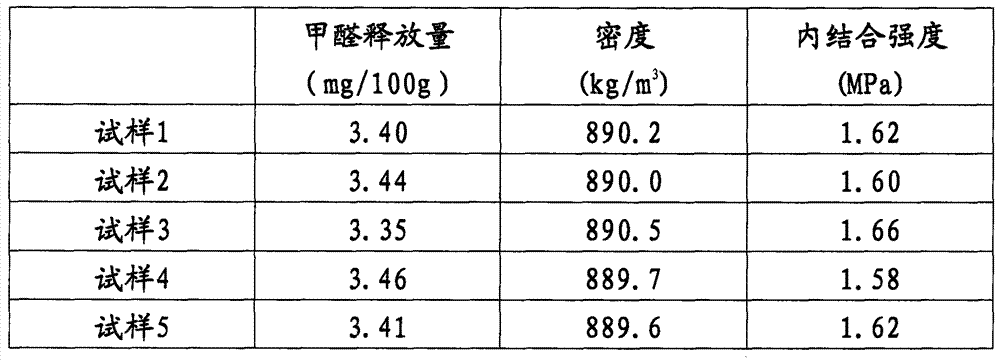

Embodiment 2

[0063] 167 parts by weight of fiber slurry, 20 parts by weight of urea-formaldehyde resin, and 11 parts by weight of propyl benzoate are uniformly mixed in a stirring tank, and the mixture is dried at 60-70°C until the water content is 10 wt%, to obtain a mixture. The mixture was pre-pressed at 6-7MPa for 40s to form a blank, and the blank was isostatically pressed at 8MPa and 70°C for 50s to form a slab. The slab is hot-pressed, and the hot-pressing conditions are: temperature 150-160°C; rise to 19-21MPa within 20-30s, hold pressure for 50-100s; decompress to 6-8.5MPa within 10-15s, hold Press for 65-135s; then rise to 10-14MPa within 10-15s, hold the pressure for 50-75s; finally depressurize uniformly to 0MPa within 60-120s. The hot-pressed plate was cooled to normal temperature, tempered and sanded to obtain a high-density fiberboard B with a thickness of 30 mm.

[0064] It has been determined that the composition of the high-density fiberboard B is 76wt% fiber, 15wt% urea...

Embodiment 3

[0066] 140 parts by weight of fiber slurry, 15 parts by weight of modified urea-formaldehyde resin, and 4.5 parts by weight of propyl benzoate were uniformly mixed in a stirring tank, and the mixture was dried at 80° C. until the moisture content was 10 wt % to obtain a mixture. The mixture is pre-pressed at 6-7MPa for 1min to form a blank, and the blank is isostatically pressed at 8-9MPa and 60-70°C for 50s to form a slab. The slab is hot-pressed, and the hot-pressing conditions are: temperature 150-160°C; rise to 19-21MPa within 20-30s, hold pressure for 50-100s; decompress to 6-8.5MPa within 10-15s, hold Press for 65-135s; then rise to 10-14MPa within 10-15s, hold the pressure for 50-75s; finally depressurize uniformly to 0MPa within 60-120s. The hot-pressed sheet was cooled to normal temperature, tempered, and sanded to obtain a high-density fiberboard C with a thickness of 30 mm.

[0067] It has been determined that the composition of the high-density fiberboard C is 85 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Moisture content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com