Wire saw for cutting pipelines

A technology for cutting pipes and wire saw machines, which is applied in the direction of sawing machine devices, metal sawing equipment, sawing machine attachments, etc., and can solve the problems of cold cutting methods that are technically difficult, not suitable for underwater operations, and not environmentally friendly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

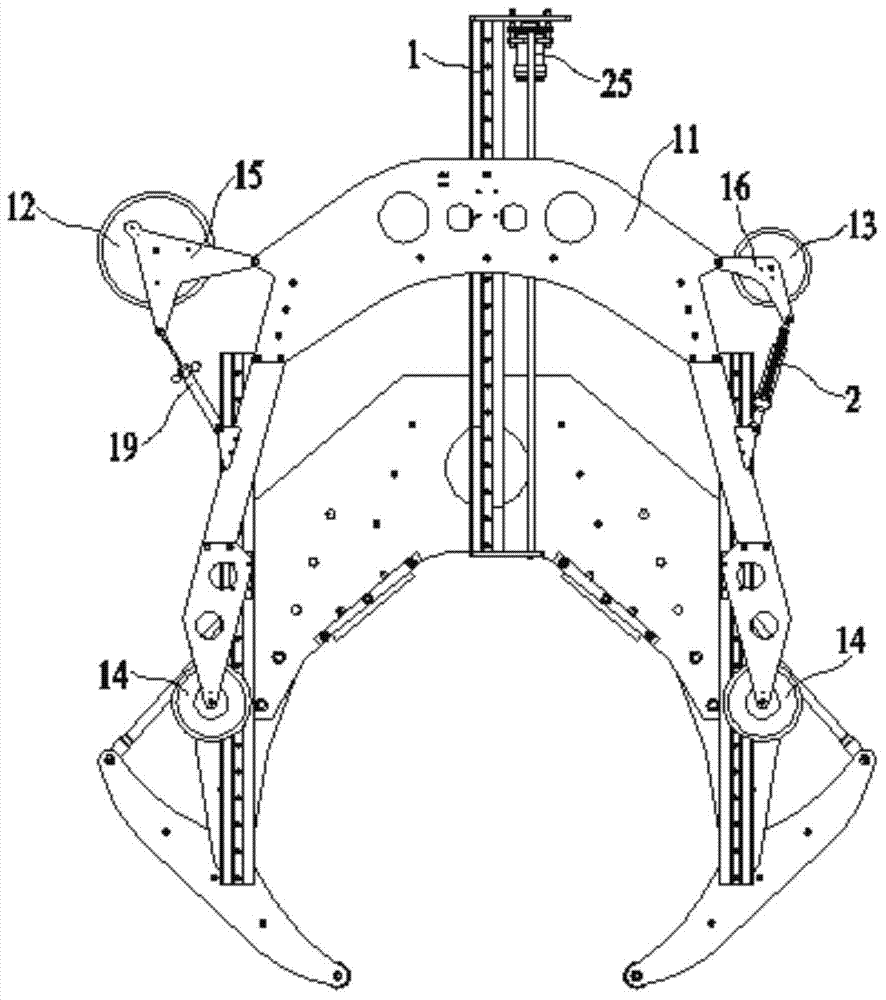

[0036] Embodiment: A wire saw machine for cutting pipes includes a support frame 1, an adaptive tension adjustment mechanism 2, a cutting mechanism 3, and a clamping mechanism 4. The cutting mechanism 3 and the clamping mechanism 4 are respectively located in the support frame 1. On both sides

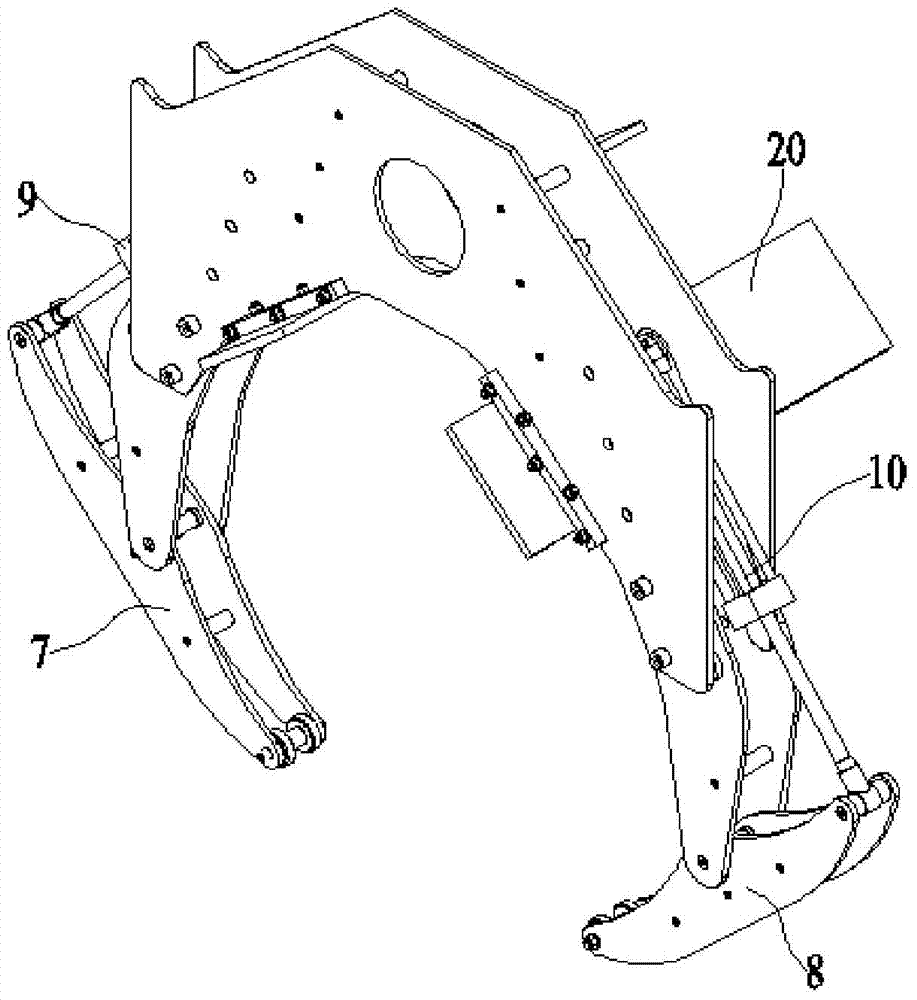

[0037] The clamping mechanism 4 includes a front clamping plate 5, a rear clamping plate 6, a left clamping jaw 7, a right clamping jaw 8, and left and right air cylinders 9, 10 installed between the front clamping plate 5 and the rear clamping plate 6. The left clamping jaw 7 The respective centers of the right clamping jaws 8 are respectively clamped and movably connected by the left and right ends of the front clamping plate 5 and the rear clamping plate 6. The upper ends of the left clamping jaws 7 and the right clamping jaws 8 are respectively connected with the left and right cylinders 9, 10 Mandrel connection;

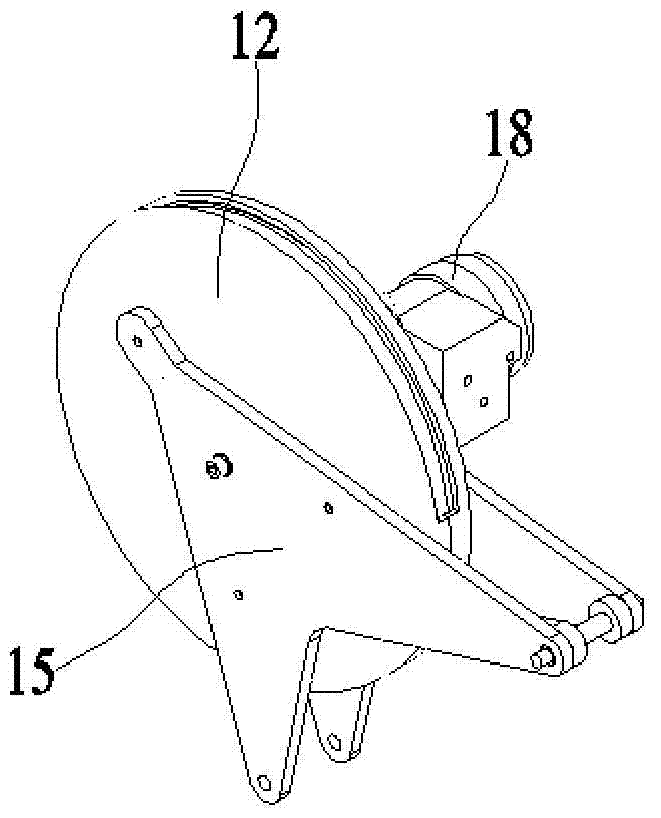

[0038] The cutting mechanism 3 includes a frame body 11, a driving whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com