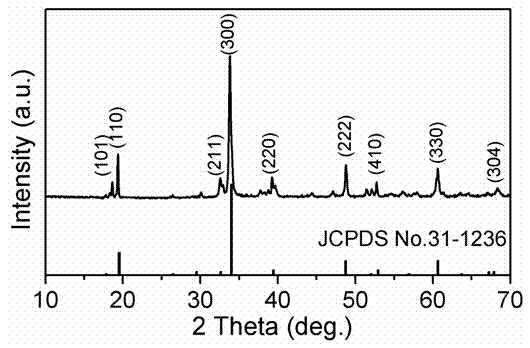

Mesoporous silver carbonate nanorod visible light photocatalyst and preparation method thereof

A technology of nanorods and silver carbonate, which is applied in chemical instruments and methods, physical/chemical process catalysts, silver compounds, etc., to achieve the effects of simple preparation methods, many reactive sites, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

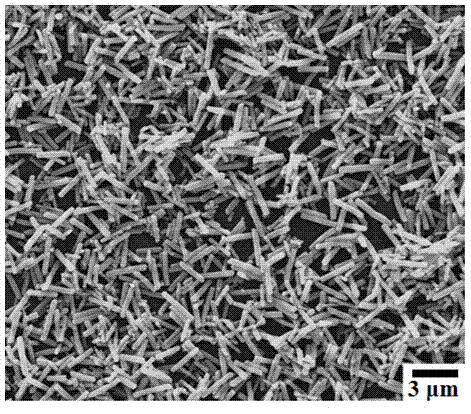

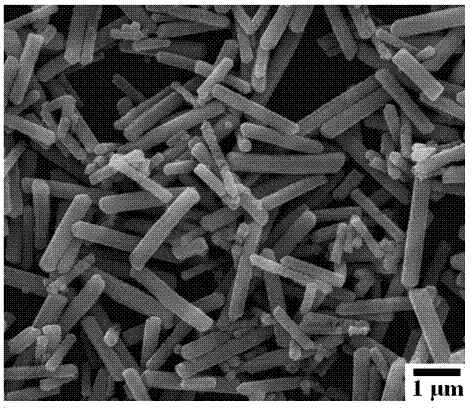

[0026] The diameter of each nanorod in the mesoporous silver carbonate nanorod visible light catalyst is 200~300nm, the length is 2~3μm, and the average pore diameter is 3~4nm; the degradation efficiency of the mesoporous silver carbonate nanorod visible light catalyst to methylene blue in 28min under visible light conditions Reached 96%.

[0027] The preparation method of the above-mentioned mesoporous silver carbonate nanorod visible light catalyst, its concrete steps are as follows:

[0028] Step 1. First, add 0.17 g of silver nitrate to 40 mL of deionized water and stir evenly to obtain a silver nitrate solution with a concentration of 0.025 mol / L;

[0029] Step 2. Add 0.05 g of polyvinylpyrrolidone (2 g in total) to the silver nitrate solution prepared in step 1 according to adding 0.05 g of polyvinylpyrrolidone to each milliliter of silver nitrate solution and stir fully to obtain a mixed solution;

[0030] Step 3. At room temperature, add a sodium bicarbonate solution ...

Embodiment 2

[0039] The mesoporous silver carbonate nanorod visible light catalyst, the diameter of the nanorod in the mesoporous silver carbonate nanorod visible light catalyst is 200~300nm, the length is 2~3μm, and the average pore diameter is 3~4nm; Under the conditions, the degradation efficiency of methylene blue reached 94% within 28 minutes.

[0040] The preparation method of the above-mentioned mesoporous silver carbonate nanorod visible light catalyst, its concrete steps are as follows:

[0041] Step 1. First, add 0.68 g of silver nitrate to 80 mL of deionized water and stir evenly to obtain a silver nitrate solution with a concentration of 0.05 mol / L;

[0042] Step 2. Add 0.025 g of polyvinylpyrrolidone (2 g in total) to the silver nitrate solution prepared in step 1 according to every milliliter of silver nitrate solution, and add polyvinylpyrrolidone to obtain a mixed solution;

[0043] Step 3. At room temperature, add a sodium bicarbonate solution with a concentration of 0.1m...

Embodiment 3

[0046] The diameter of the nanorods in the mesoporous silver carbonate nanorod visible light catalyst is 200~300nm, the length is 2~3μm, and the average pore diameter is 3~4nm; the degradation efficiency of the mesoporous silver carbonate nanorod visible light catalyst to methylene blue reaches 95% in 28min under the condition of visible light. %.

[0047] The preparation method of the above-mentioned mesoporous silver carbonate nanorod visible light catalyst, its concrete steps are as follows:

[0048] Step 1. First, add 0.17 g of silver nitrate to 40 mL of deionized water and stir evenly to obtain a silver nitrate solution with a concentration of 0.025 mol / L;

[0049] Step 2. Add 0.025 g of polyvinylpyrrolidone (1 g in total) to the silver nitrate solution prepared in step 1 according to adding 0.025 g of polyvinylpyrrolidone to each milliliter of silver nitrate solution and stir fully to obtain a mixed solution;

[0050] Step 3. At room temperature, add a sodium bicarbonat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com