Oil water separation nanofiber membrane with CO2 stimulus response as well as preparation method and application thereof

A nanofiber membrane, oil-water separation technology, applied in separation methods, liquid separation, semi-permeable membrane separation and other directions, can solve the problems affecting the reversibility of the system circulation, diluted solution, salt accumulation, etc., to achieve low price, efficient preparation process, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1, the preparation of oil-water separation nanofibrous membrane

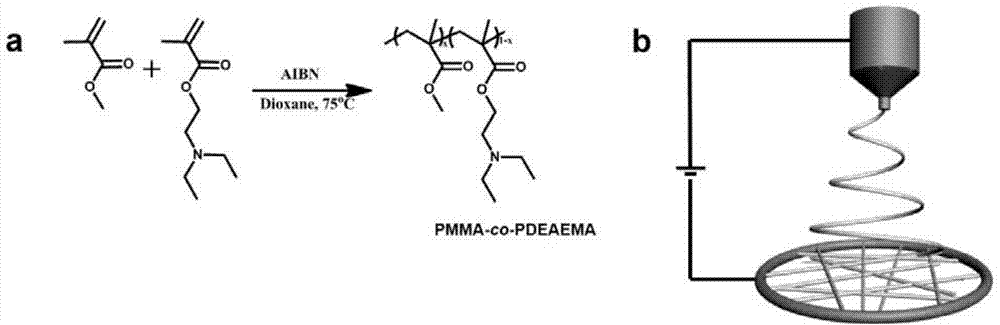

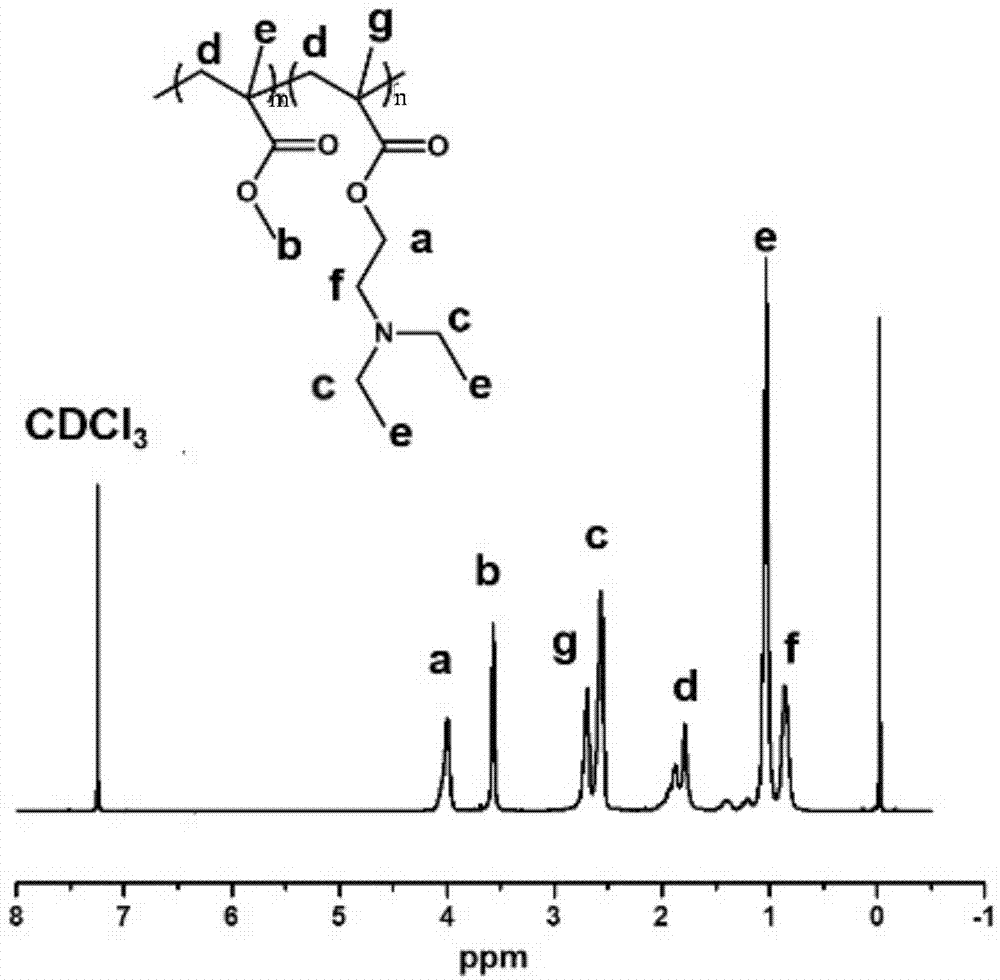

[0053] (1) Synthesis of random copolymer PMMA-co-PDEAEMA

[0054] as per figure 1 Synthetic steps shown in (a) are synthesized: in a 100mL round bottom flask, monomer methyl methacrylate (abbreviated as MMA, 4.0g, 40mmol), DEAEMA (11g, 60mmol) and initiator azobisisobutyl Nitrile (abbreviated as AIBN, 33 mg, 0.2 mmol) was dissolved in 50 mL of dioxane, and magnetically stirred for half an hour. Subsequently, the reaction solution was subjected to liquid nitrogen freezing-gas pumping-nitrogen gas filling, each pumping for 15 minutes, and the cycle was repeated three times. After the oxygen in the reaction system was completely removed, it was under the protection of nitrogen. The reaction bottle was placed in a 75°C oil bath, stirred by a magnet, and reacted for 24 hours. After the reaction, the reaction bottle was quickly placed in liquid nitrogen, and the gas was vented to communicate with...

Embodiment 2

[0067] Embodiment 2, the preparation of oil-water separation nanofibrous membrane

[0068] (1) Synthesis of random copolymer PMMA-co-PDEAEMA

[0069] as per figure 1 (a) Synthetic steps shown in: In a 100mL round bottom flask, monomer MMA (2.0g, 20mmol) and DEAEMA (11g, 60mmol), initiator AIBN (11mg, 0.07mmol) were dissolved in 40mL of dioxygen In six rings, stir magnetically for half an hour. Subsequently, the reaction solution was subjected to liquid nitrogen freezing-gas pumping-nitrogen gas filling, each pumping for 15 minutes, and the cycle was repeated three times. After the oxygen in the reaction system was completely removed, it was under the protection of nitrogen. The reaction bottle was placed in a 75°C oil bath, stirred by a magnet, and reacted for 20 hours. After the reaction, the reaction bottle was quickly placed in liquid nitrogen, and the gas was vented to communicate with the atmosphere to terminate the reaction. After the system was cooled to room tempe...

Embodiment 3

[0080] Embodiment 3, the preparation of oil-water separation nanofibrous membrane

[0081] (1) Synthesis of random copolymer PMMA-co-PDEAEMA

[0082] The preparation method is the same as in Example 1.

[0083] (2) Preparation of PMMA-co-PDEAEMA spinning solution

[0084] The preparation method is the same as in Example 2.

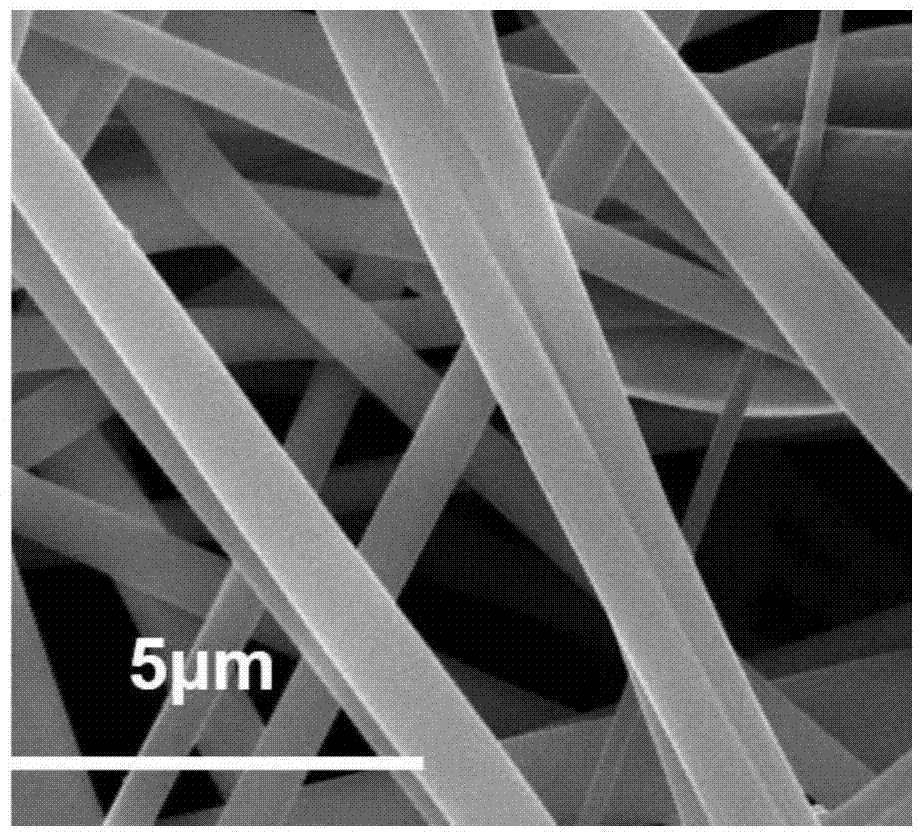

[0085] (3) Preparation of PMMA-co-PDEAEMA nanofibrous membrane

[0086] Such as figure 1 As shown in (b), the spinning solution obtained in step (2) was placed in a 2mL syringe containing a metal nozzle (16 gauge), the distance between the nozzle and the cylindrical receiver was 20cm, and the injection speed was set to 1mL h -1 , the voltage is set to 20kV. When the nanofibers are interwoven and arranged, the ambient temperature is 35° C., the humidity is 54%, and the time is 12 hours. The obtained nanofiber membrane is dried in a vacuum oven at 50° C. for 24 hours to obtain an oil-water separation nanofiber membrane with a thickness of 110 μm.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com