Sound-absorbing panels

A technology for sound-absorbing panels and substrates, which is used in sound-emitting equipment, railway car body parts, instruments, etc., can solve the problems of inability to meet the heat resistance, melting and dripping resistance of railway vehicles, and achieve the effect of improving sound absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

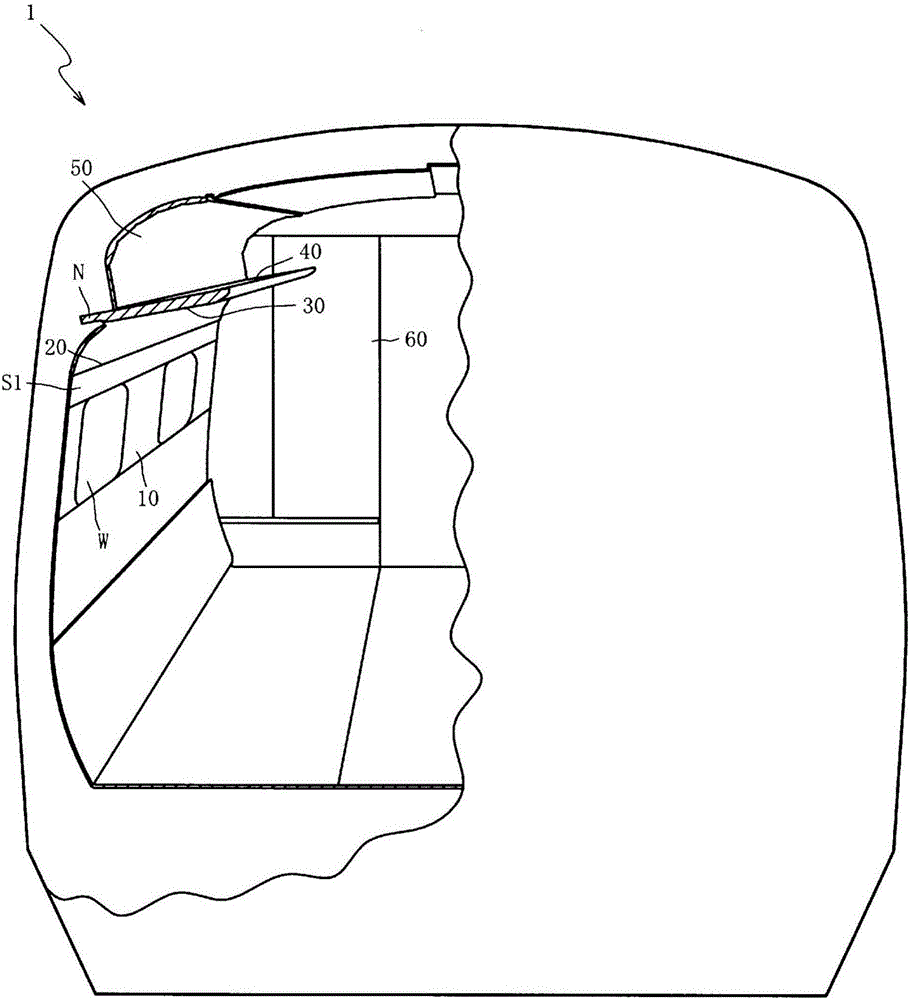

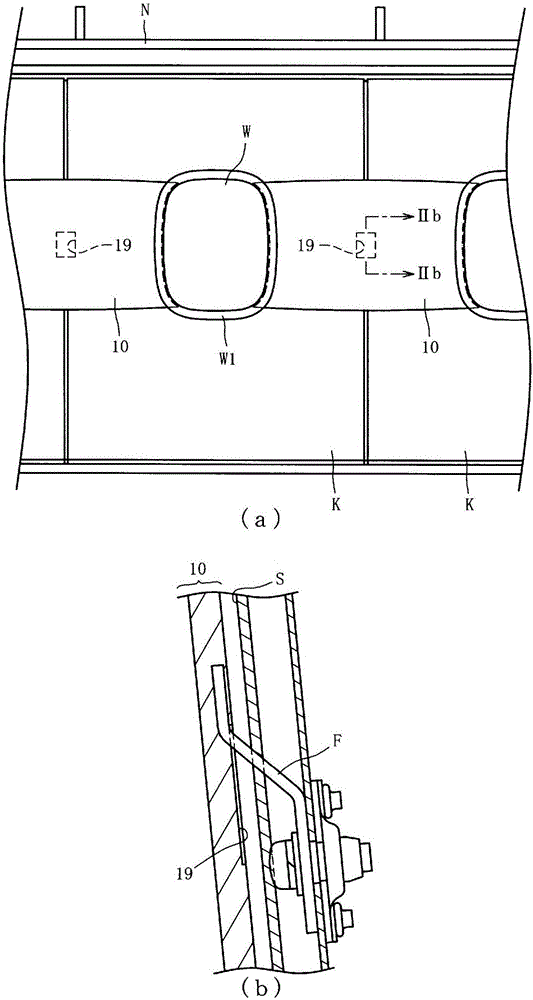

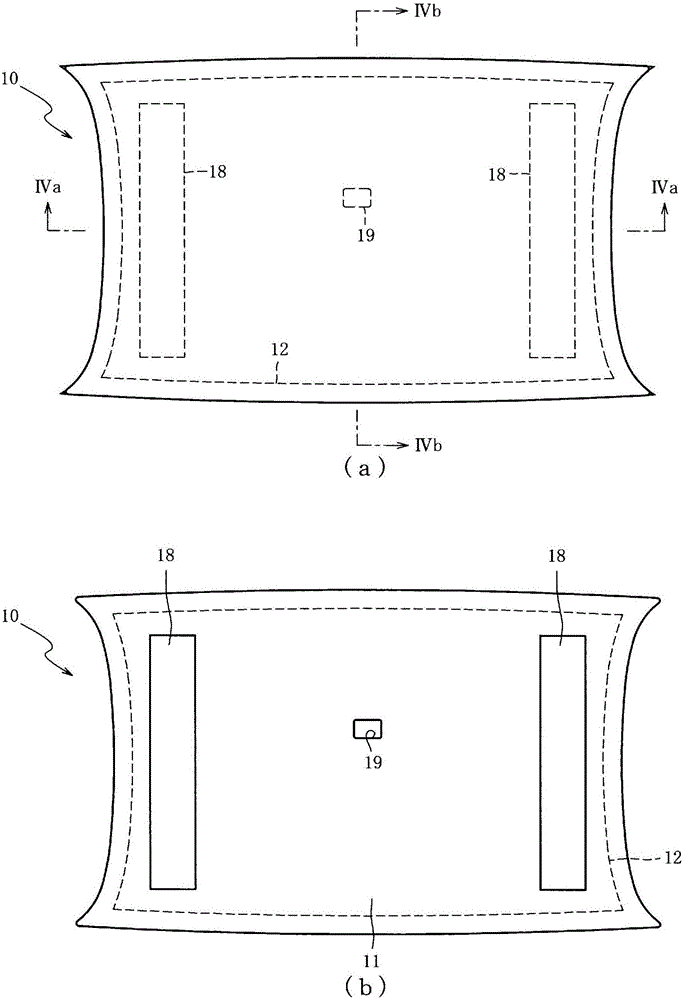

[0033] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings. First, the position of the railway vehicle 1 to which the sound-absorbing panel of the present invention is mounted will be described. figure 1 It is a schematic diagram showing the passenger compartment of a railway vehicle 1 . and, in figure 1 In , illustration of seats etc. is omitted.

[0034] In the passenger compartment of the railway vehicle 1, a plurality of windows W are arranged on the inner wall surface of the passenger compartment at predetermined intervals along the longitudinal direction; A seat number plate (not shown), clothes hooks (not shown), etc. are arranged; and a luggage rack N protrudes from the upper inner wall of the space S1 toward the passenger compartment.

[0035] The sound-absorbing panels of the present invention include: window-side sound-absorbing panels 10, upper side wall sound-absorbing panels 20, luggage rack lower sound-ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com