Lens testing and calibration device

A lens and test board technology, used in installation, television, optics, etc., can solve the problems of low production efficiency and high work intensity, and achieve the effects of high production efficiency, easy operation and labor-saving operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

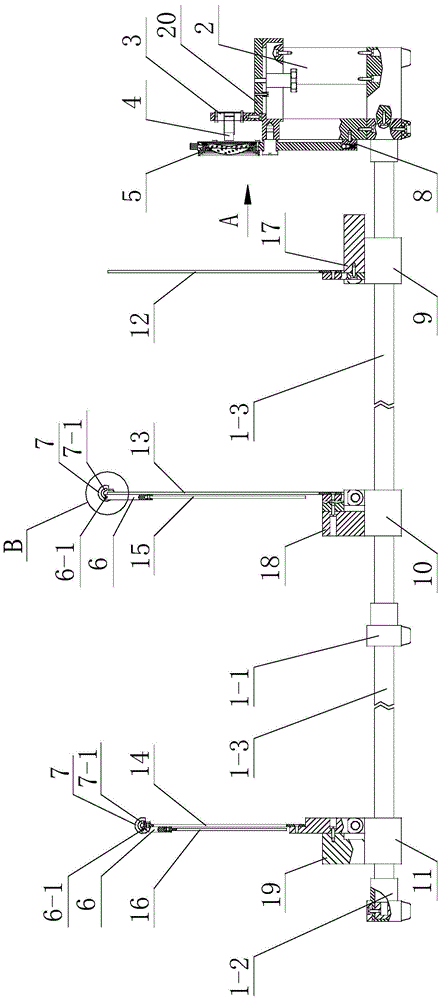

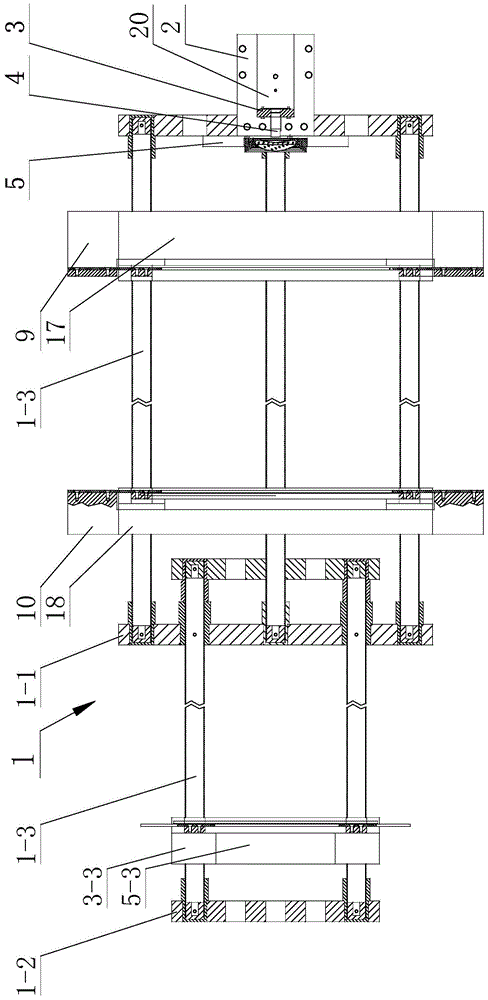

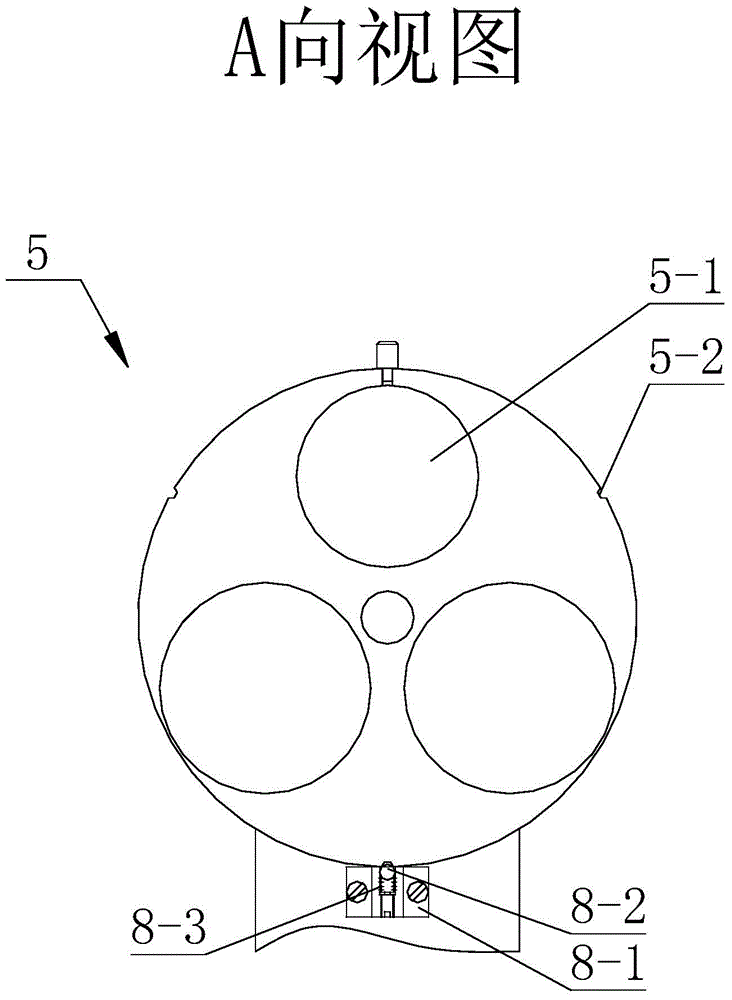

[0027] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments of the description:

[0028] like figure 1 - Figure 4 As shown, a lens testing and adjusting device provided by the present invention is characterized in that it includes a base 1, a test base 2 fixed at one end of the base 1, and a camera for installing a camera 3 on the test base 2 Mounting seat 20, described video camera 3 is provided with the connection lens barrel that is used to install tested lens 4; Described lens test, adjusting device also comprises the close-up lens that is arranged in sequence in front of tested lens 4 detection positions along light incident direction Place the turntable 5 and more than two groups of test plate devices; the close-up lens is placed on the turntable 5 and is rotatably connected to the test seat 2 and is provided with a plurality of spacers distributed on the different radial direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com