Three-dimensional oil suction fabric

A three-dimensional, fabric technology, applied in the direction of fabrics, textiles, textiles and papermaking, etc., can solve the problems of unfavorable industrial production research and development and control, unfavorable industrial production, and difficulties in industrial production, and achieve good recovery of adsorption capacity and excellent mechanical properties , The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

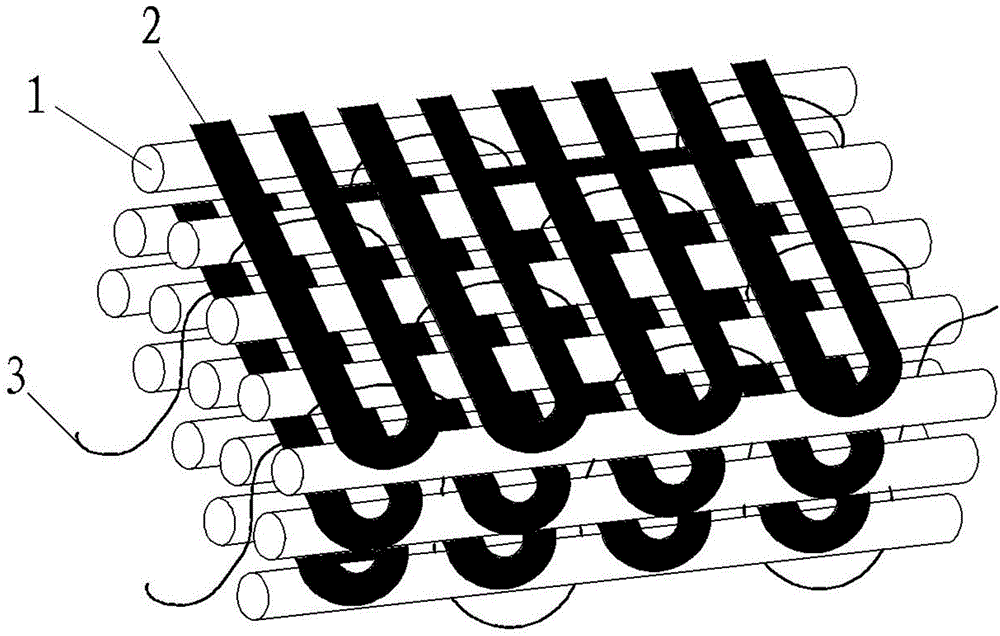

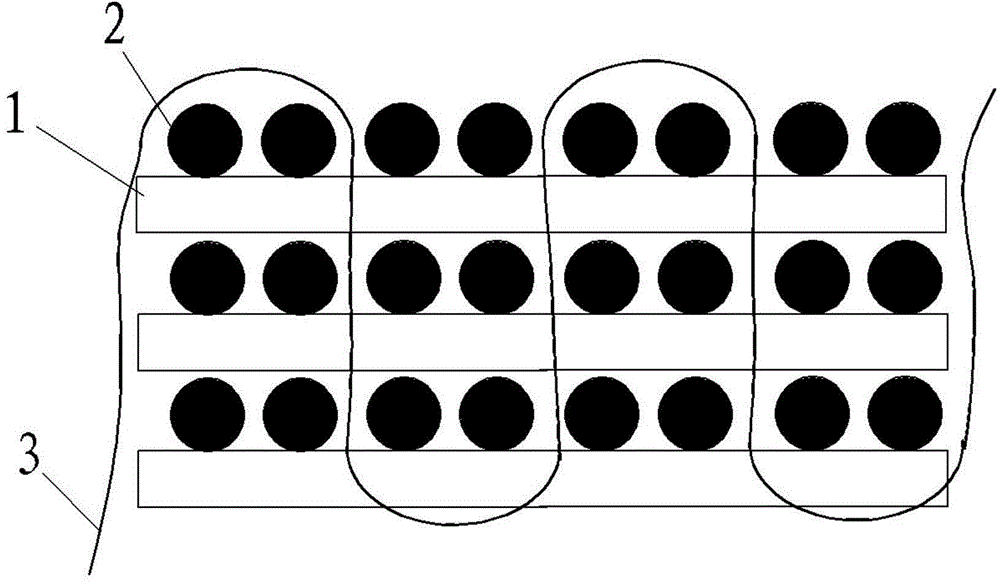

[0028] Such as figure 1 and figure 2 As shown, a three-dimensional oil-absorbing fabric includes yarns in X direction, Y direction and Z direction. The yarns in X direction are polylactic acid fibers with a fineness of 7.8dtex prepared by wet spinning technology, and the fibers in Y direction are The yarns are flax fibers with a denier of 6.4dtex and a strength of 5.4cN / dtex, and the yarns in the Z direction are bamboo fibers with a hemicellulose content of 23% and a denier of 4.2dtex.

[0029] The yarns in the X direction, Y direction and Z direction are woven into a square three-dimensional oil-absorbing fabric using three-dimensional weaving technology. The thickness of the three-dimensional oil-absorbing fabric is 2mm, and the content of polylactic acid fiber is 45%.

Embodiment 2

[0031] Such as figure 1 and figure 2 As shown, a three-dimensional oil-absorbing fabric includes yarns in X direction, Y direction and Z direction. The yarns in X direction are polylactic acid fibers with a fineness of 7.8dtex prepared by wet spinning technology, and the fibers in Y direction are The yarn is carboxylic acid-modified chitosan fiber with a denier of 3.6dtex and a strength of 4.6cN / dtex, and the yarn in the Z direction is a polylactic acid fiber with a denier of 7.8dtex prepared by wet spinning technology.

[0032] The yarns in the X direction, Y direction and Z direction are woven into a circular three-dimensional oil-absorbing fabric using three-dimensional weaving technology. The thickness of the three-dimensional oil-absorbing fabric is 158mm, and the content of polylactic acid fiber is 67%.

Embodiment 3

[0034] Such as figure 1 and figure 2 As shown, a three-dimensional oil-absorbing fabric includes yarns in X direction, Y direction and Z direction. The yarns in X direction are polylactic acid fibers with a fineness of 7.8dtex prepared by wet spinning technology, and the fibers in Y direction are The yarn prepared by wet spinning technology is a polylactic acid fiber with a fineness of 7.8dtex, and the yarn in the Z direction is a flax fiber with a fineness of 6.4dtex and a strength of 5.4cN / dtex.

[0035] The X-direction yarn, Y-direction yarn and Z-direction yarn are woven into an I-shaped three-dimensional oil-absorbing fabric using three-dimensional weaving technology. The thickness of the three-dimensional three-dimensional oil-absorbing fabric is 87mm, and the content of polylactic acid fiber is 69%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com