A kind of color-changing environmental protection coating and preparation method thereof

An environmentally friendly coating and raw material technology, applied in the coating and other directions, can solve the problems of long over-temperature discoloration reaction time, the coating cannot be reused, and the warning error is large, and achieves extensive industrial use, reversible discoloration effect, and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] According to the ratio of components by weight, 40 parts of bismuth vanadate, 10 parts of Haibi, 10 parts of Al2O3, 20 parts of talcum powder, and 8 parts of mica powder are added to 30 parts of epoxy-modified silicone resin, and stearin 2 parts of acid glycerides, disperse for 20 minutes with 2000 rev / min rotating speed; add xylene and organic silicon coupling agent in the obtained mixture, keep rotating speed and disperse for 8 minutes; In the mixture, the rotation speed is 1600 rpm, and disperse for 8 minutes; while stirring and dispersing, add 1 part of modified polyurea N-methylpyrrolidone anti-settling agent and 3 parts of organosiloxane defoamer in sequence , dispersed for 10 minutes, and filtered to obtain the corresponding product A.

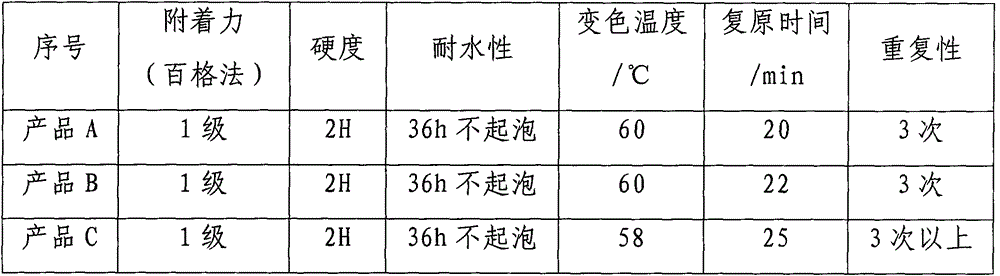

[0038] The performance test was carried out on the above-mentioned product A, and the results are shown in Table 1.

Embodiment 2

[0040] According to the ratio of components by weight, 45 parts of bismuth vanadate, 12 parts of Haibi, 12 parts of Al2O3, 24 parts of talcum powder, and 12 parts of mica powder are added to 35 parts of epoxy-modified silicone resin, and stearin 3 parts of acid glycerides, dispersed for 25 minutes at 2200 rev / min; add xylene and organic silicon coupling agent to the obtained mixture, keep the rotating speed for 9 minutes; add polyvinyl alcohol to the obtained mixture according to the components In the mixture, the rotation speed is 1800 rpm, and disperse for 9 minutes; while stirring and dispersing, add 2 parts of modified polyurea N-methylpyrrolidone anti-settling agent and 4 parts of organosiloxane defoamer in sequence , dispersed for 12 minutes, and filtered to obtain the corresponding product B.

[0041] The performance test was carried out on the above-mentioned product B, and the results are shown in Table 1.

Embodiment 3

[0043] According to the ratio of components by weight, 50 parts of bismuth vanadate, 15 parts of Haibi, 15 parts of Al2O3, 30 parts of talc powder, and 15 parts of mica powder were added to 40 parts of epoxy modified silicone resin, and three hard 4 parts of fatty acid glycerides, disperse at 2400 rpm for 30 minutes; add xylene and silicone coupling agent to the obtained mixture, keep the speed of dispersion for 10 minutes; add polyvinyl alcohol to the previous step according to the components to obtain In the mixture, the rotating speed is 2000 rev / min, disperse for 10 minutes; while keeping stirring and dispersing, add 3 parts of modified polyurea N-methylpyrrolidone anti-settling agent and 5 parts of organosiloxane defoamer in sequence parts, dispersed for 15 minutes, and filtered to obtain the corresponding product C.

[0044] The performance test was carried out on the above-mentioned product C, and the results are shown in Table 1.

[0045] Table 1

[0046]

[0047]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com