Safe environment-friendly colorful firecracker reagent and method for preparing colorful firecracker by using reagent

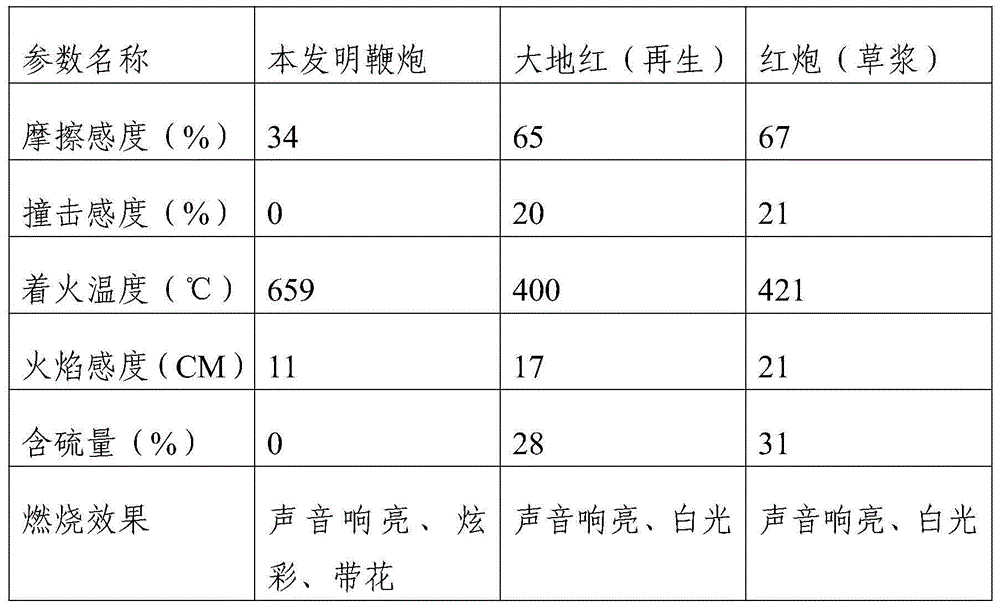

A safe, environmentally friendly and colorful technology, used in explosives, offensive equipment, pyrotechnics, etc., can solve the problems of reducing the stability of the chemical, poor thermal stability, affecting the environment, etc., achieving low friction sensitivity and flame sensitivity, crisp sound, Fast response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

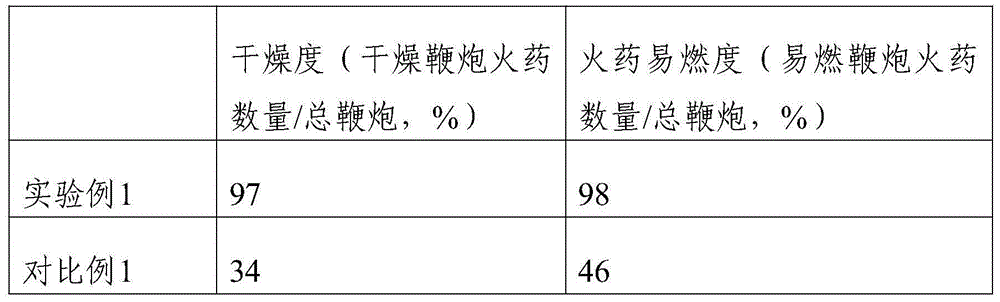

Examples

Embodiment 1

[0029] 1. Preparation of raw materials for safe and environmentally friendly colorful firecrackers

[0030] Component A is composed of the following raw materials: 10kg perchlorate, 2kg nano-carbon, 3kg chlorinated rubber, 50kg nitrate, 2kg aluminum powder, 4kg aluminum-magnesium alloy powder, 1kg antimony trioxide; The mixture of potassium chlorate and ammonium perchlorate, the mixing ratio is 15:1; the nitrate is the mixture of potassium nitrate and barium nitrate, the mixing ratio is 1:4;

[0031] Component B consists of the following raw materials: 30kg perchlorate, 30kg nitrate, 10kg aluminum-magnesium alloy powder, 1kg vitrified microspheres, 2kg microcrystalline wax, 2kg acrylic acid, 2kg phenolic resin, 4kg absolute ethanol, perchloric acid The salt is potassium perchlorate, and the nitrate is barium nitrate; among them, microcrystalline wax, acrylic acid, phenolic resin, and absolute ethanol are stored separately before use.

[0032] The above-mentioned component A a...

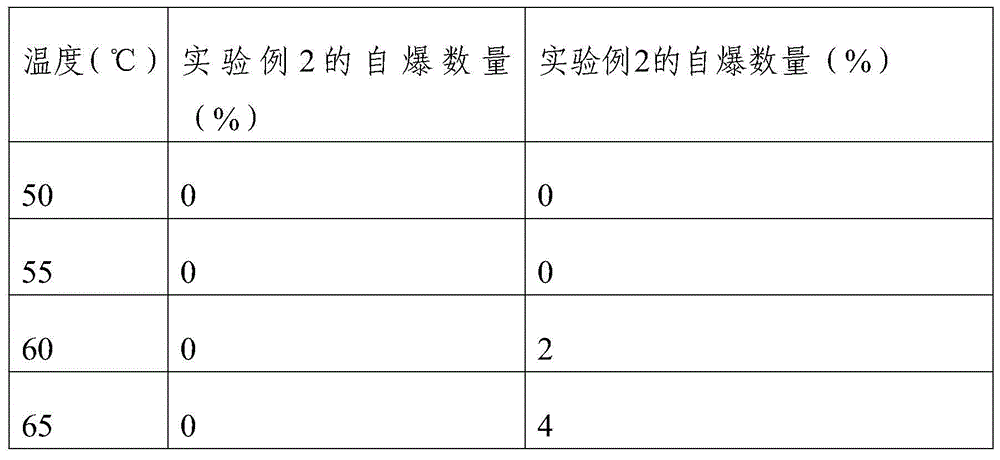

Embodiment 2

[0041] 1. Preparation of raw materials for safe and environmentally friendly colorful firecrackers

[0042] Component A consists of the following raw materials: 70kg of perchlorate, 10kg of nano-carbon, 20kg of chlorinated rubber, 40kg of nitrate, 10kg of aluminum powder, 30kg of aluminum-magnesium alloy powder, and 3kg of antimony trioxide; where perchlorate is high The mixture of potassium chlorate and ammonium perchlorate, the mixing ratio is 15:1; the nitrate is the mixture of potassium nitrate and barium nitrate, the mixing ratio is 1:4;

[0043] Component B consists of the following raw materials: 70kg perchlorate, 40kg nitrate, 20kg aluminum-magnesium alloy powder, 10kg vitrified microspheres, 5kg microcrystalline wax, 5kg acrylic acid, 5kg phenolic resin, 4-20kg absolute ethanol, high The chlorate is potassium perchlorate, and the nitrate is barium nitrate; wherein microcrystalline wax, acrylic acid, phenolic resin, and absolute ethanol are stored separately.

[0044]...

Embodiment 3

[0053] 1. Preparation of raw materials for safe and environmentally friendly colorful firecrackers

[0054]Component A is composed of the following raw materials: 4kg perchlorate, 5kg nano-carbon, 10kg chlorinated rubber, 20kg nitrate, 5kg aluminum powder, 15kg aluminum-magnesium alloy powder, 2kg antimony trioxide; The mixture of potassium chlorate and ammonium perchlorate, the mixing ratio is 15:1; the nitrate is the mixture of potassium nitrate and barium nitrate, the mixing ratio is 1:4;

[0055] Component B consists of the following raw materials: 50kg perchlorate, 35kg nitrate, 15kg aluminum-magnesium alloy powder, 5kg vitrified microspheres, 4kg microcrystalline wax, 3kg acrylic acid, 3kg phenolic resin, 12kg absolute ethanol, perchloric acid The salt is potassium perchlorate, and the nitrate is barium nitrate; among them, microcrystalline wax, acrylic acid, phenolic resin, and absolute ethanol are stored separately.

[0056] The above-mentioned component A and compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com