Device for extracting protein from corn starch wastewater and preparation method for device

A corn starch and protein technology, applied in the field of protein extraction, can solve the problems of high cost, cumbersome process, excessive discharge and other problems, and achieve the effects of eliminating environmental pollution, simple process and preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

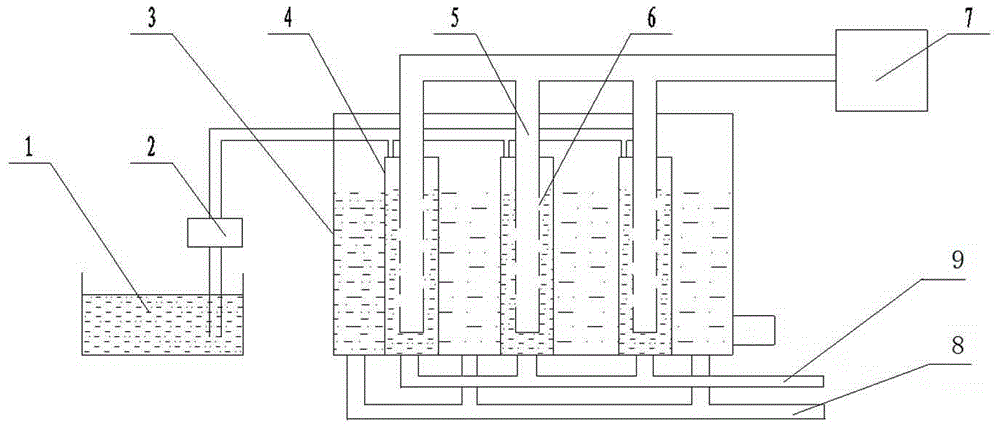

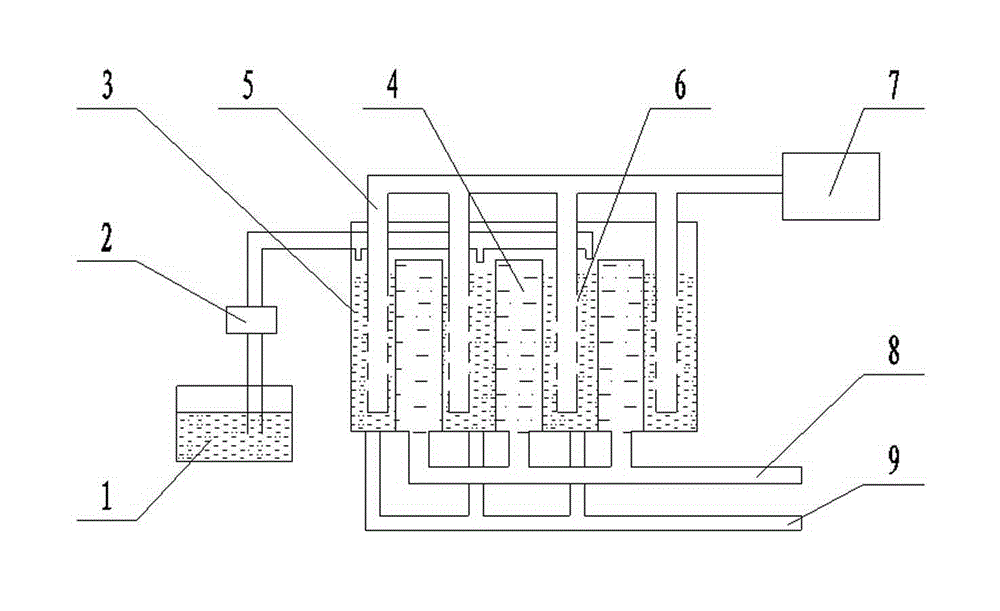

[0015] The cornstarch wastewater protein extraction device includes a membrane separator and a regulating water tank 1 connected to the cornstarch wastewater. A high-pressure water pump 2 is arranged on the pipeline between the regulating water tank 1 and the membrane separator. The membrane separator includes a housing 3, and the housing 3. Several tubular membranes 4 are arranged at the bottom, and an air duct 5 with a bottom end sealing is arranged near the tubular membrane 4. A plurality of vortex holes 6 arranged along the tangential direction of the duct wall are opened on the air duct 5. The upper end of the air duct 5 is provided with Have the air pump 7 that communicates with it.

[0016] The air duct 5 is arranged at the center of the tubular membrane 4, the bottom of the casing 3 is provided with an outlet pipe 8, and the casing 3 at the lower end of the tubular membrane 4 is provided with a concentrate outlet pipe 9; the number of the air ducts 5 is several, and is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com