Railway transportation torpedo car brake device

A technology for a torpedo tank car and a braking device, which is used in transportation and packaging, railway car body parts, pneumatic brakes, etc. Influence, safe and reliable parking brake, high effect of parking safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

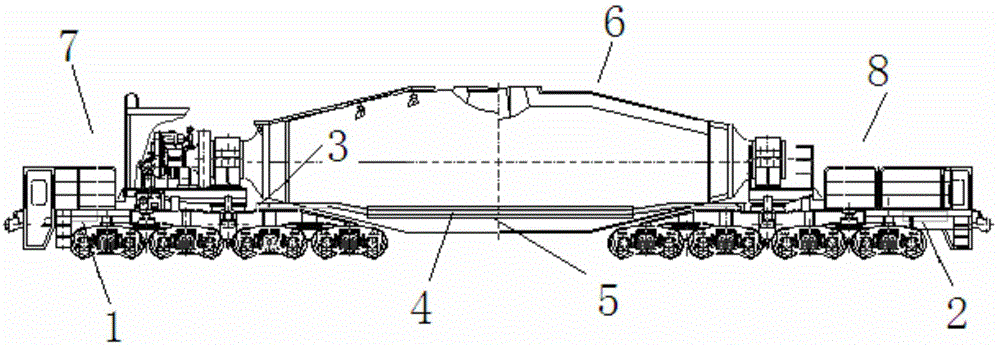

[0019] Such as figure 1 As shown, a brake device for a torpedo tank car includes a left brake unit 1, a right brake unit 2, and a brake main air duct 3. In the space near the right side of the bottom, the left brake unit 1 is arranged in the space of the underframe 7 of the running part of the left end of the torpedo tank body near the bottom of the left side of the middle beam, and the right brake unit 2 is arranged in the space of the bottom of the torpedo tank body. The underframe 8 of the running part at the right end of the tank car body is in the space near the bottom of both sides of the middle beam on the right side, which solves the influence of the high temperature of the tank body on the wind source, and designs the air brake unit into two parts, which are respectively instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com