Electro-hydraulic combined braking system with retardance braking function

A slow braking, electro-hydraulic compound technology, applied in electric braking systems, braking transmissions, brakes, etc., can solve the problems of limited braking capacity, small braking torque, etc., to reduce the frequency of use and reduce pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The structure and working principle of the electro-hydraulic composite braking system with retarding braking function involved in the present invention will be described in detail below in conjunction with the accompanying drawings.

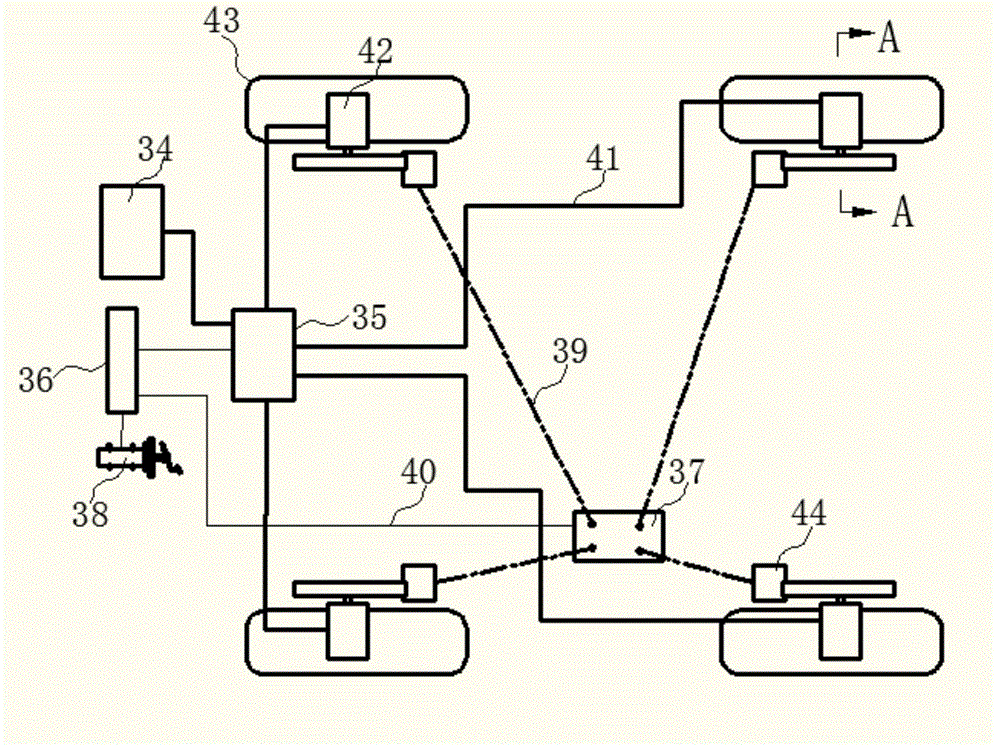

[0027] The electro-hydraulic composite braking system with retarding braking function includes a hydraulic braking subsystem, a motor braking subsystem and a control subsystem. The hydraulic brake subsystem consists of a hydraulic regulator 37 , an electronic brake pedal 38 , a brake pipeline 39 and a double disc brake 44 . The motor braking subsystem consists of a power battery 34 , a DC / AC converter 35 , a power line 41 and a motor 42 ; the control subsystem includes an electronic control unit 36 and a signal line 40 .

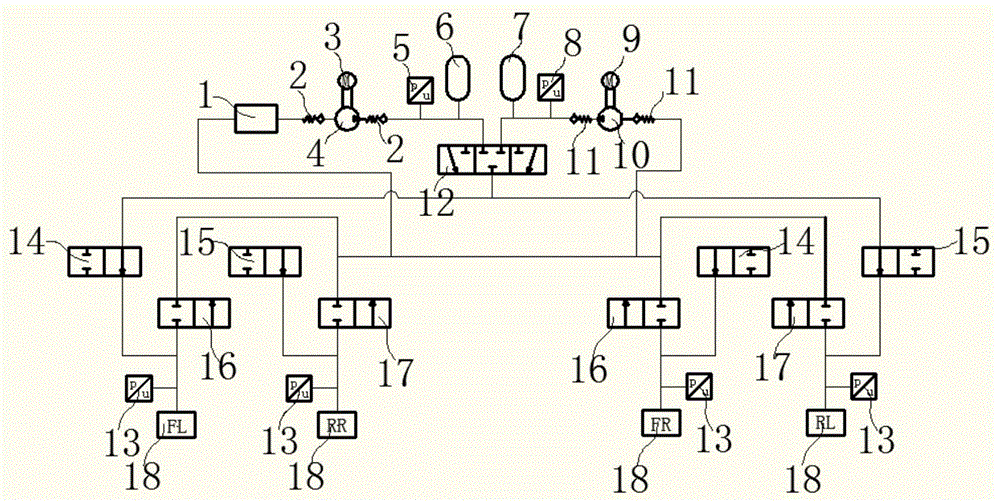

[0028] Such as figure 1As shown, the oil tank 1 is connected to the liquid inlet of the high-pressure pump 4 through the check valve 2, the liquid outlet of the high-pressure pump 4 is connected to the liquid outlet o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com