A raw material vibrating and homogenizing device for the production of composite material boards

A composite material board and raw material technology, which is applied in the field of raw material vibration and homogenization device, can solve the problems of affecting air permeability and sound absorption, low efficiency, raw material compaction, etc., and achieve good material uniformity, ingenious structure, excellent air permeability and sound absorption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

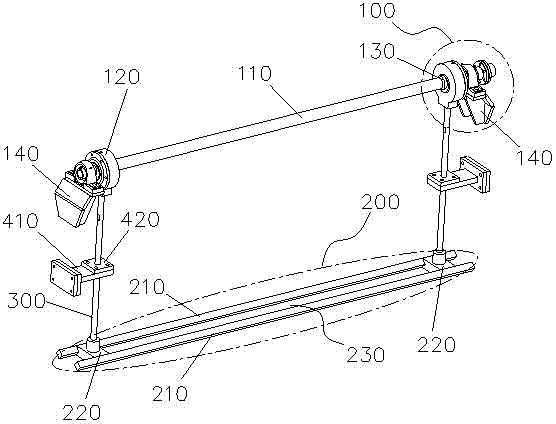

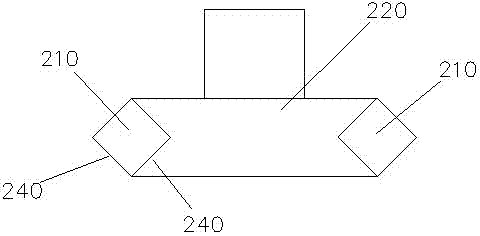

[0015] The invention discloses a vibrating and homogenizing device for raw materials used in the production of composite material boards, such as figure 1 As shown, it includes a power structure 100 and a pounding structure 200. The power structure 100 is connected to the pounding structure 200 through a connecting rod 300. The power structure 100 drives the pounding structure 200 to shake repeatedly up and down, so as to realize pounding and squeezing of the raw materials on the surface of the mold. pressure.

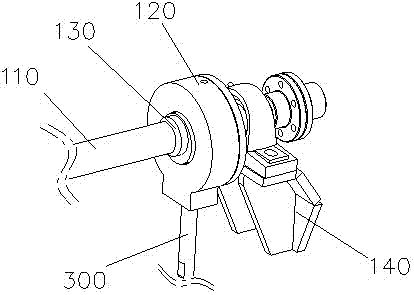

[0016] In practice, see figure 2 , the power structure 100 includes a rotating shaft 110 and a base 120 (the support seat 140 for fixing the rotating shaft 110 is provided outside the base 120), the rotating shaft 110 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com