Method and device for mechanical deinking of printing paper

A technology of printing paper and machinery, which is applied in the direction of grinding drive devices, grinding machine parts, grinding machines, etc., can solve the problems of water pollution, air pollution, large manpower, material resources and financial resources, and achieve high safety performance and energy saving Paper cost, overcoming the effect of long cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

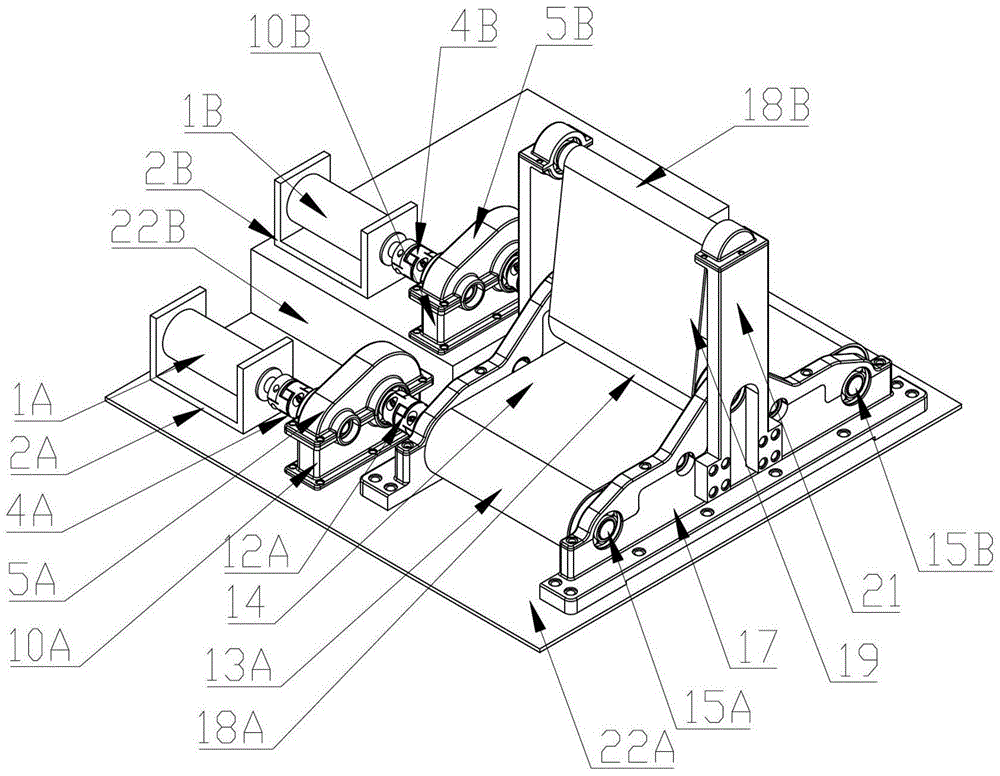

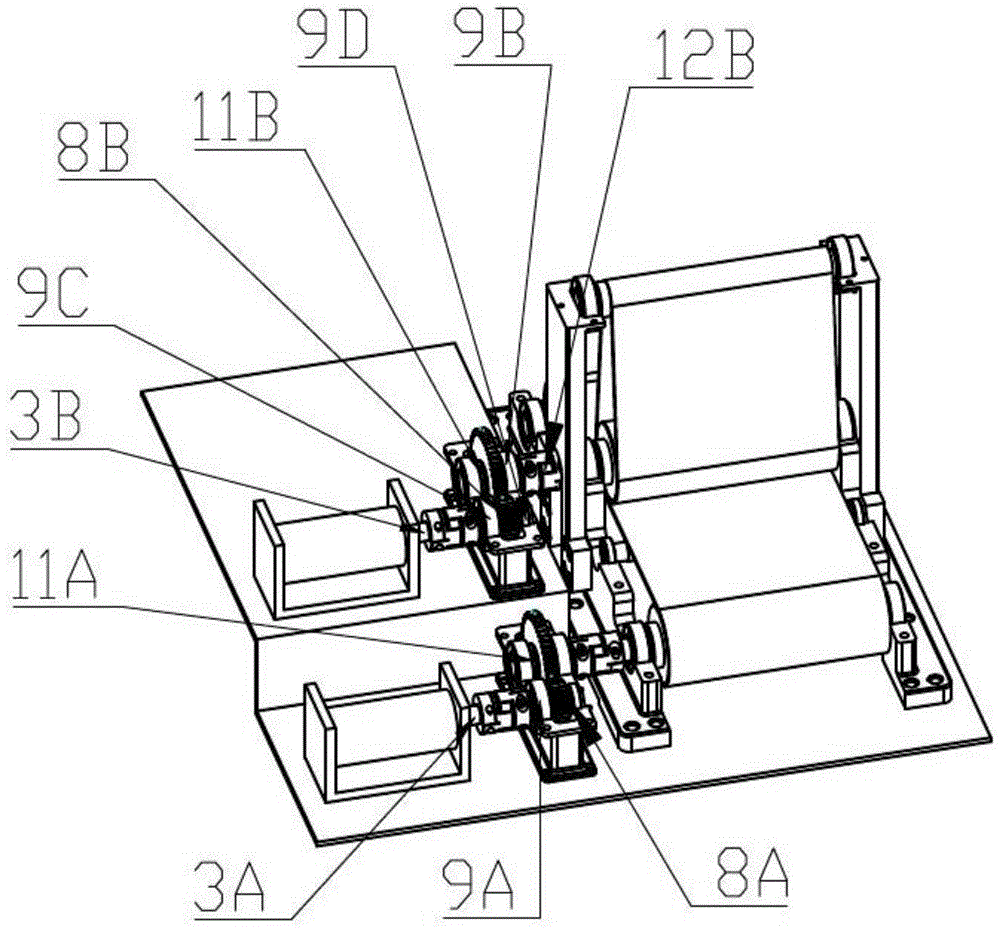

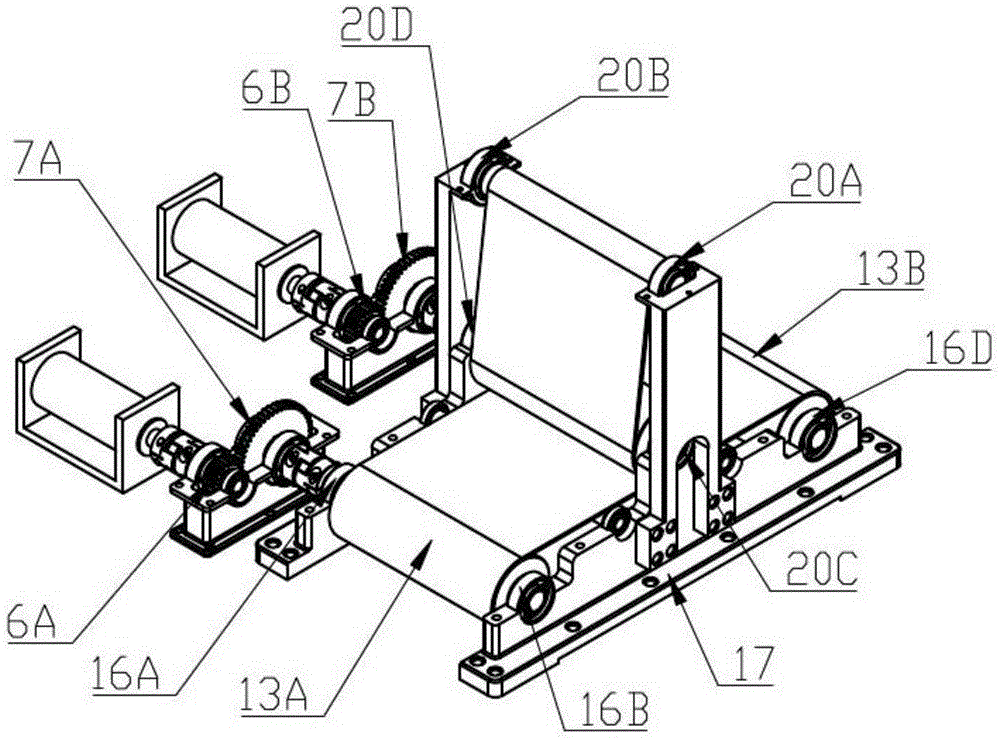

[0029] figure 1 -5 shows that a specific embodiment of the present invention is a mechanical deinking device for printing paper, including a transmission mechanism, a transmission mechanism, and a grinding mechanism, and is characterized in that:

[0030] The transmission mechanism is composed of a driving device and a reduction mechanism. The motor 1A is installed on the outer box 22A through the motor base 2A, the reducer 5A is a first-stage reducer composed of the driving gear 6A and the driven gear 7A, and the driving gear shaft 8A is connected with the motor main shaft 3A through the coupling 4A , the driving gear shaft 8A is installed on the reducer case 10A through rolling bearings (including 9A and 9B), the reducer case 10A is fixed on the outer case 22A by bolts, and the driven gear shaft 11A Pass shaft coupling 12A links to each other with the conveyor driving pulley 13A of transmission mechanism.

[0031] The transmission mechanism is composed of a driving wheel a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com