A temperature-displacement coupling device for real-time monitoring of on-line crystallizer copper plate

A technology for crystallizer copper plate and real-time monitoring, which is applied in the configuration of indicating equipment/measuring equipment, manufacturing tools, metal processing equipment, etc. Simple, reduce breakout rate, and ensure the effect of equipment reliability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

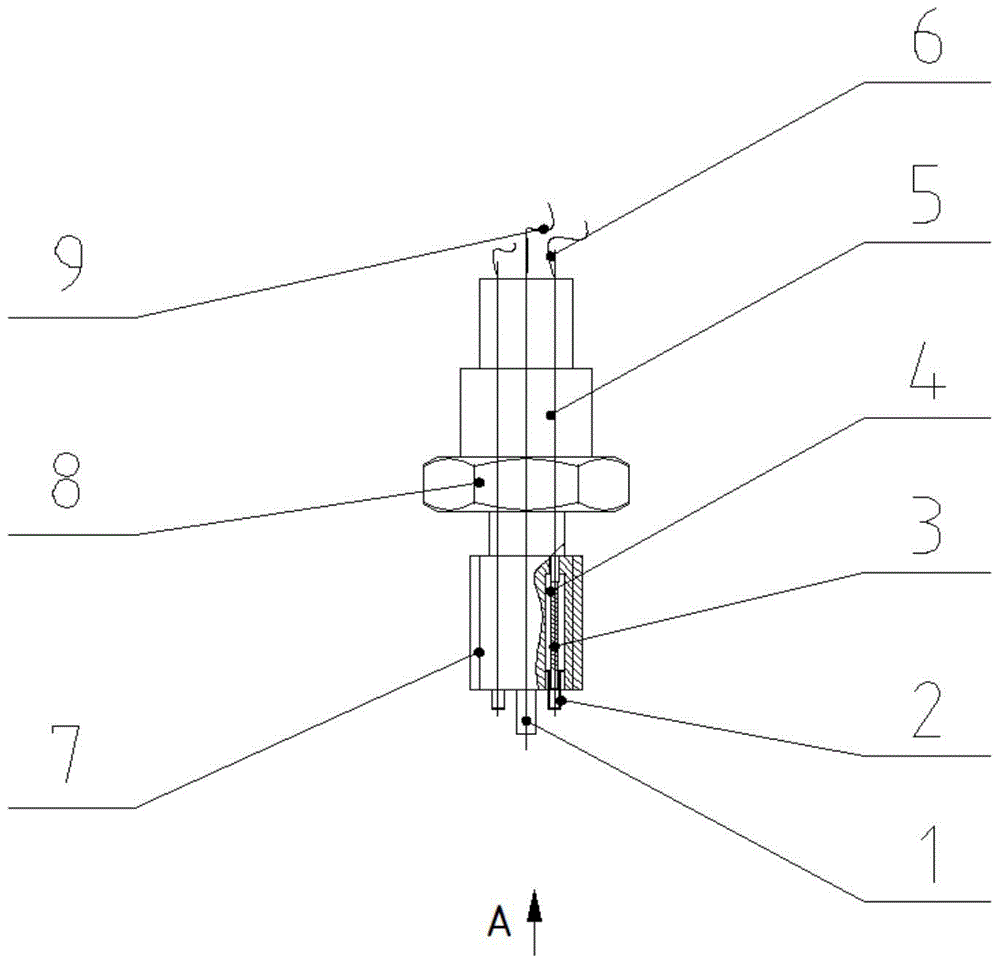

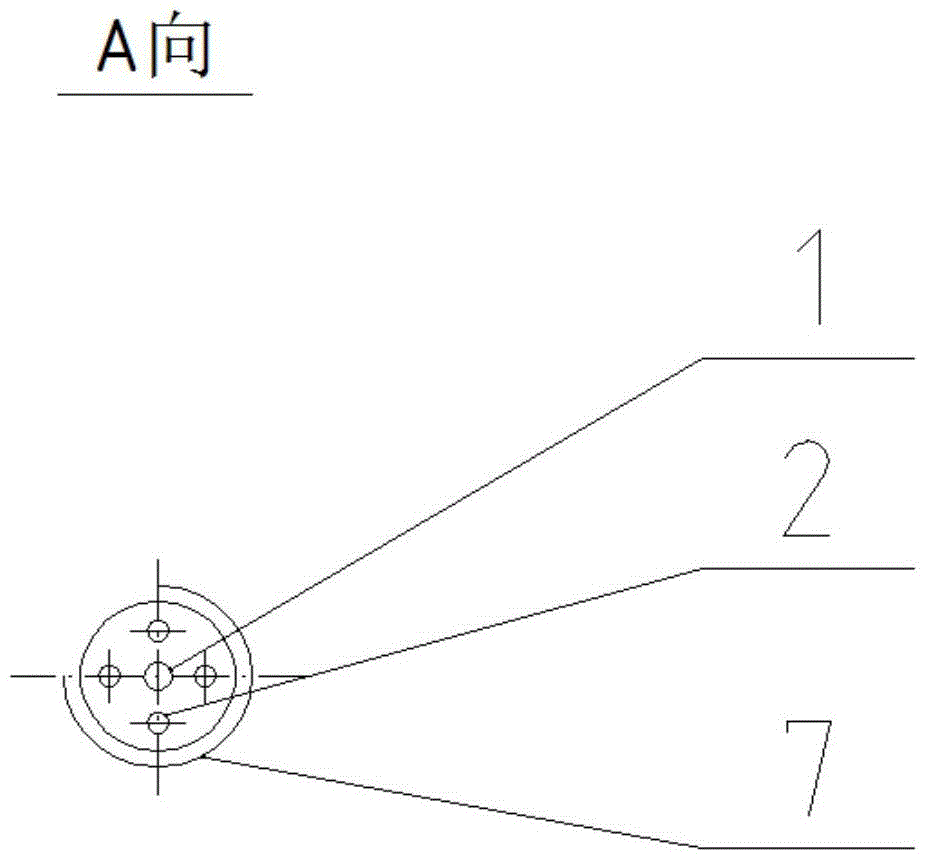

[0017] The present invention will be further described below in conjunction with accompanying drawing. Such as Figure 1-2 As shown, a temperature-displacement coupling device for real-time monitoring of an online crystallizer copper plate, including a temperature-sensing probe 1, a displacement probe 2, a spring slide 3, a guide rod 4, a ferrule device 5, a displacement compensation wire 6, and a screw sleeve 7. Fasteners 8 and temperature compensating wires 9; there are four displacement probes 2 connected to the lower ends of the respective guide rods 4, the spring slides 3 are set on the guide rods 4, and the guide rods 4 The upper ends of the rods 4 are respectively connected to the respective displacement compensation wires 6, the temperature sensing probe 1 is connected to the temperature compensation wires 9, the screw sleeve 7 has connecting threads on the outside, and there are five through holes in the inner cavity, each of which is a The temperature probe through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com